Flashforge Hunter Photopolymer 3D Printer Review

Hello! We talk about the properties of the 3D-printer company Flashforge Hunter . This is a desktop stereolithographic 3D printer that prints volumetric models with photopolymer resins . We tested the printer, printed a lot of test samples, and now we can share what we learned about it in practice.

First look

The printer looks at least interesting: futuristic design, in the style of fantastic films of the 90s, in everything: from the shape of the case, to the menu of management. Calibration is not needed, neither the platform nor the laser - it is enough to start autofocus, fill the polymer, send the model and start the printing process. Preparations for printing and launching happen quickly and without any complications.

Specifications

Material: Photopolymer resin

Printing technology: DLP;

Light source: 405 nm LED;

Projector resolution: 1920x1080 (Full HD);

Projector lifetime: 50,000 hours;

Layer thickness: 25 and 50 microns

XY axis positioning accuracy: 0.0625 mm;

Working area: 120x67.5x150 mm;

Connection interface: USB, USB drive, Wi-Fi;

Software: FlashPrint;

Supported file formats: STL;

Weight (unpacked): 17.8 kg;

Dimensions (without packaging): 360x310x565 mm;

Power supply: 100-240 V, 50-60 Hz, 1А;

Country of origin: China

Price: 275 000 rubles

Governing bodies

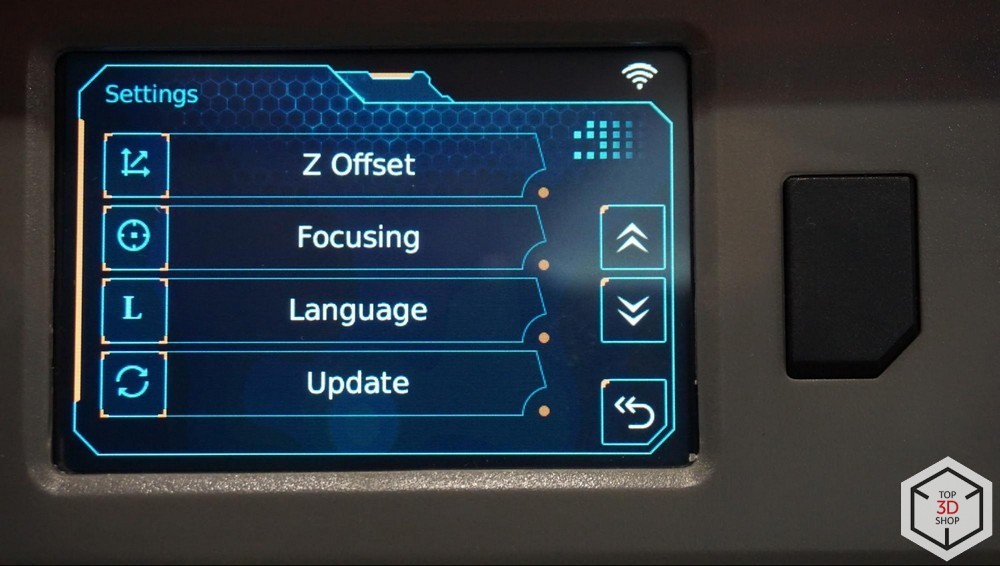

All Hunter controls - power button and touchscreen display. The printer menu consists of 2 main sections: Print - prepared files for printing and managing it, and Settings - settings.

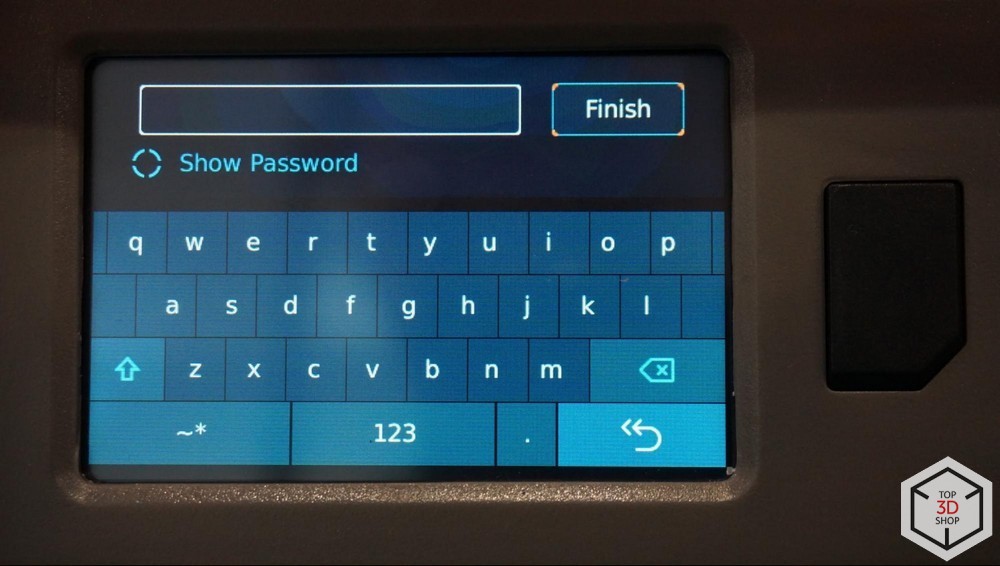

The menu itself is quite simple, stylized. In the Settings menu you can set up a Wi-Fi connection, for this PC and printer should be on the same network.

There is a standard password entry.

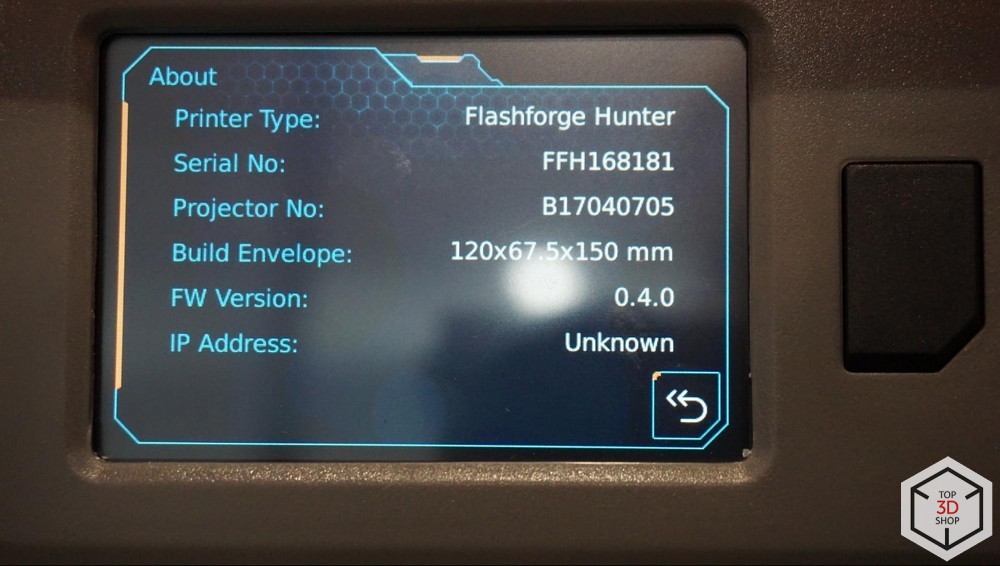

Also in the menu, you can configure the printer’s autofocus, raise and lower the platform, set the Z-axis, select a language (alas, no Russian), update the printer software and view information about it.

Compound

To receive project files, a wired connection to the computer with a USB cable, the use of flash media and a wireless connection via Wi-Fi are provided.

Device Overview

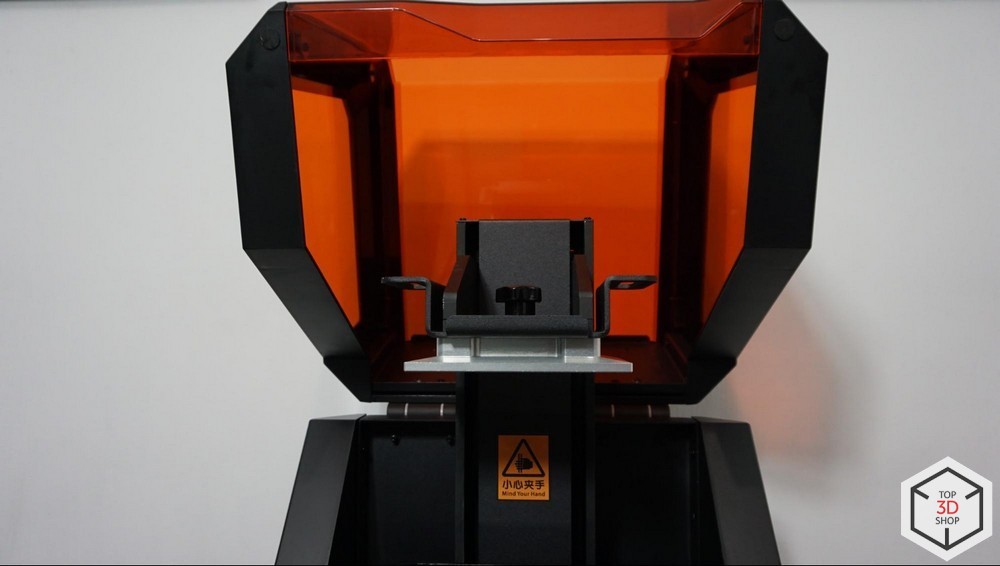

The cover is made of orange polymer to protect the resin from exposure.

There are no adjusting devices in the platform mount - calibration is not needed, autofocus copes with everything perfectly.

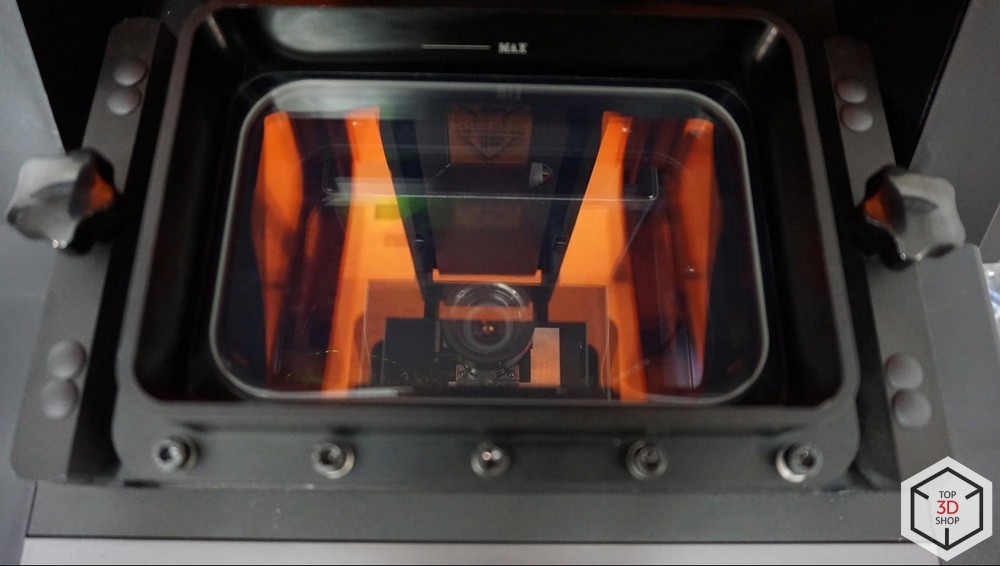

Bathroom itself is complex. It can also be called a “technically complex device” because her disassembly is impossible without the training course of the young fighter.

Its installation also does not require any adjustment.

Self-produced Z-Axis guides. Possess considerable rigidity and precision.

The construction platform has a textured surface for better adhesion of the model in the printing process.

The diode projector is protected from leakage even in the event of polymer leakage from the bath when the film is broken, but, alas, the polymer can leak into the internal cavities of the printer.

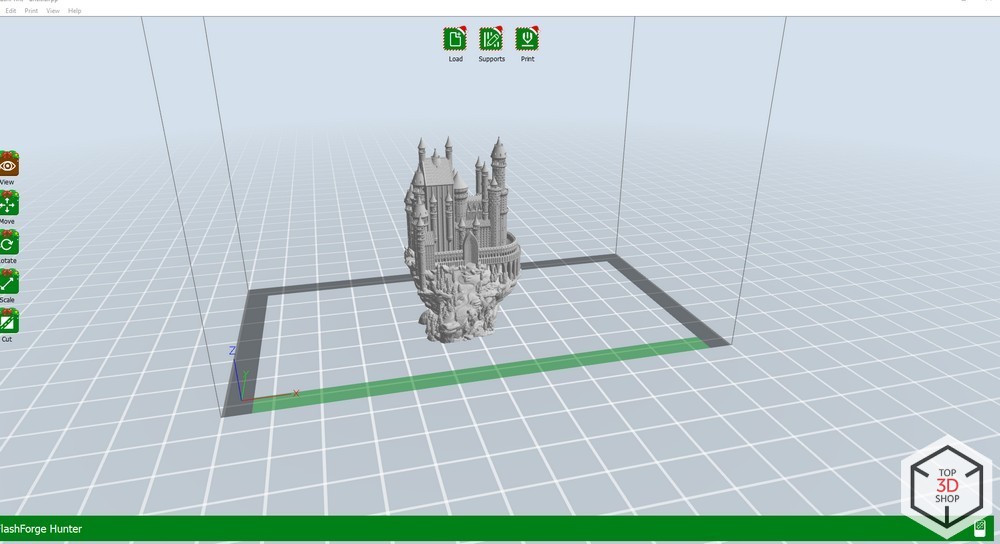

Slicer FlashPrint

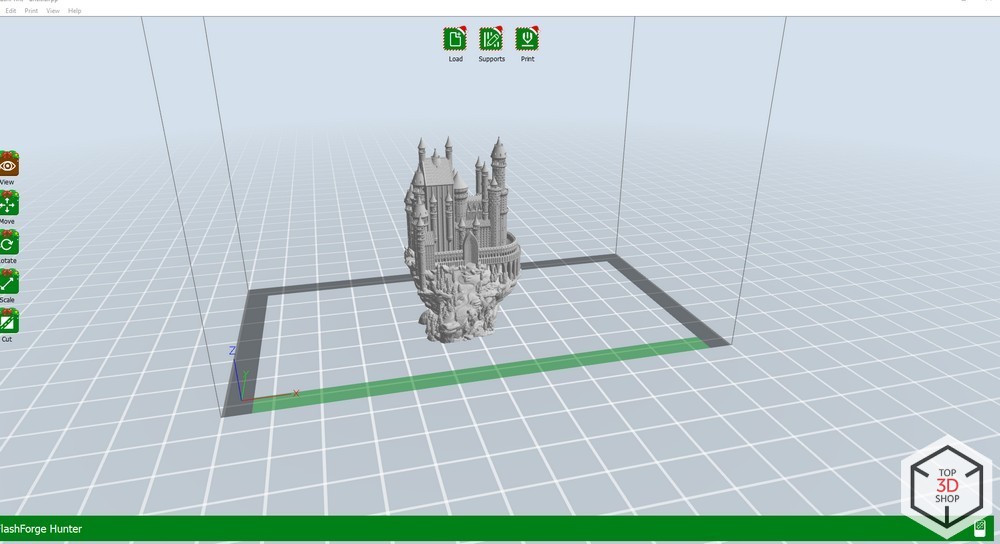

Minimalistic simple interface. On the left are the icons of view, location, rotation, zoom and cross section of the model into its component parts. There are 3 main icons at the top: model loading, support menu and final slicing.

The model can be moved in 3 planes and simply dragged along the X and Y axes.

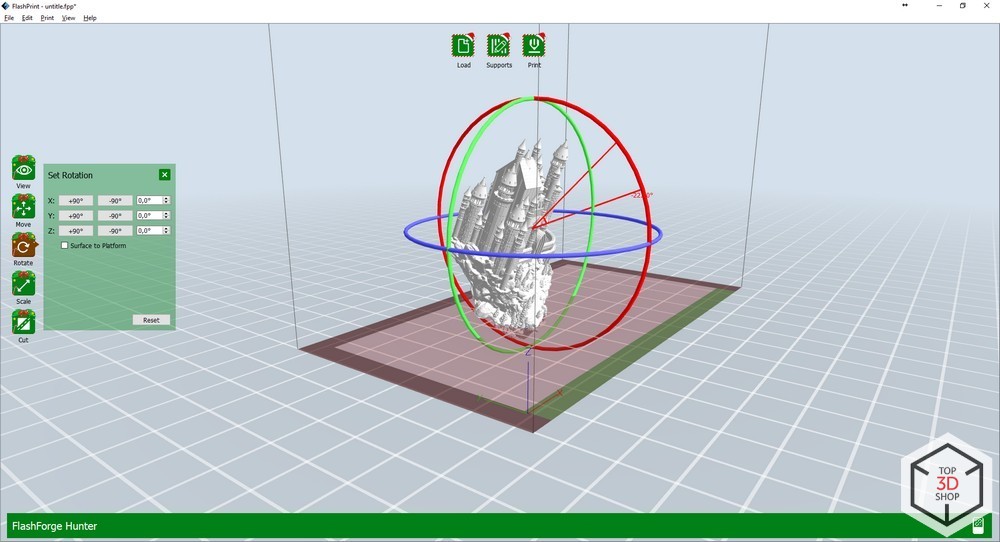

You can rotate objects both in manual mode and in degree measure. Also, holding CTRL + Z, you can cancel the action.

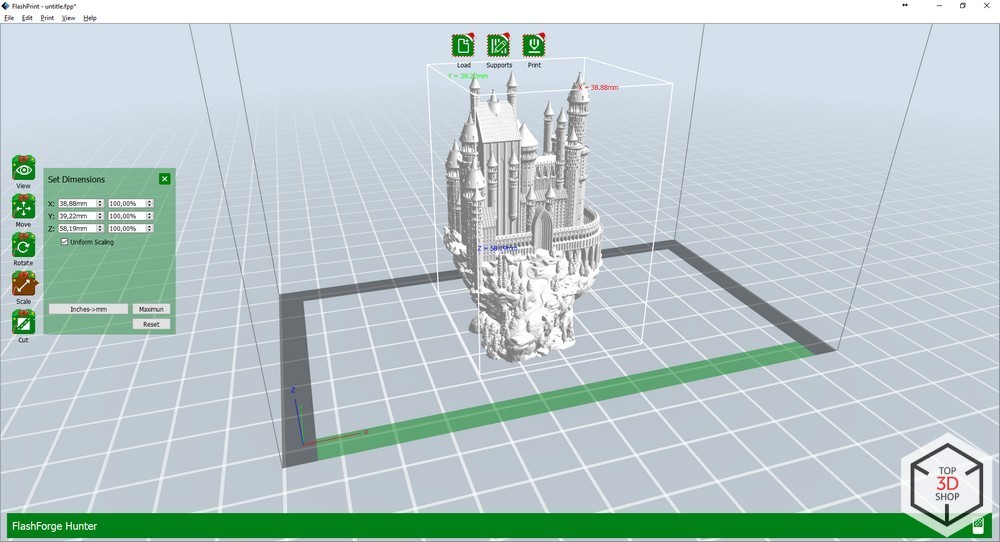

Scaling is also available manual and specified by digital value.

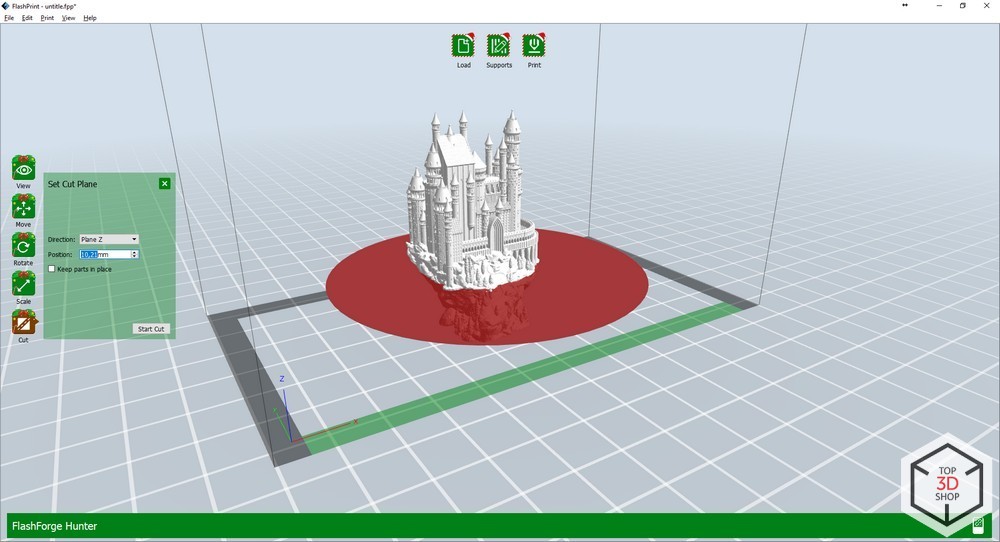

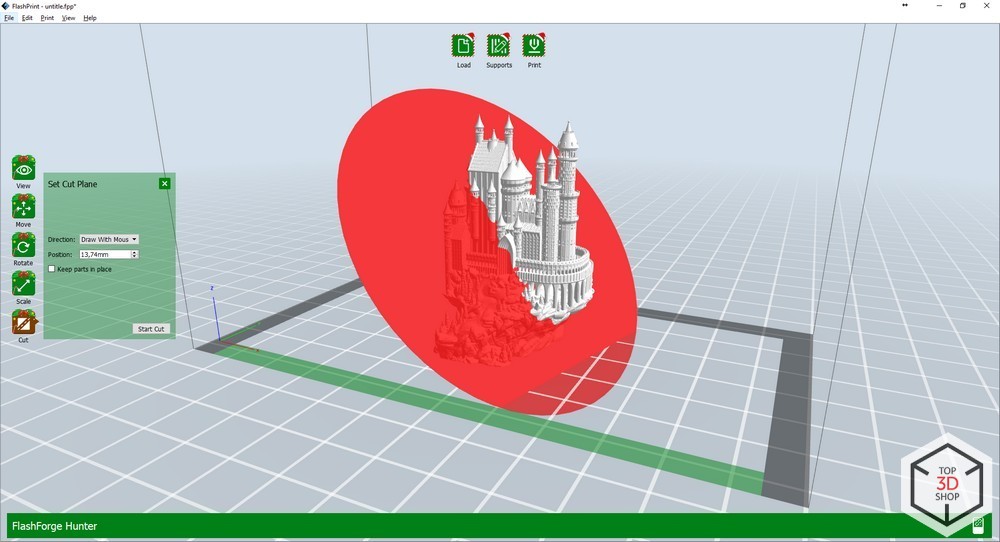

Section mode allows you to divide an object into its component parts, both in three planes and in free mode, by setting the direction with the mouse.

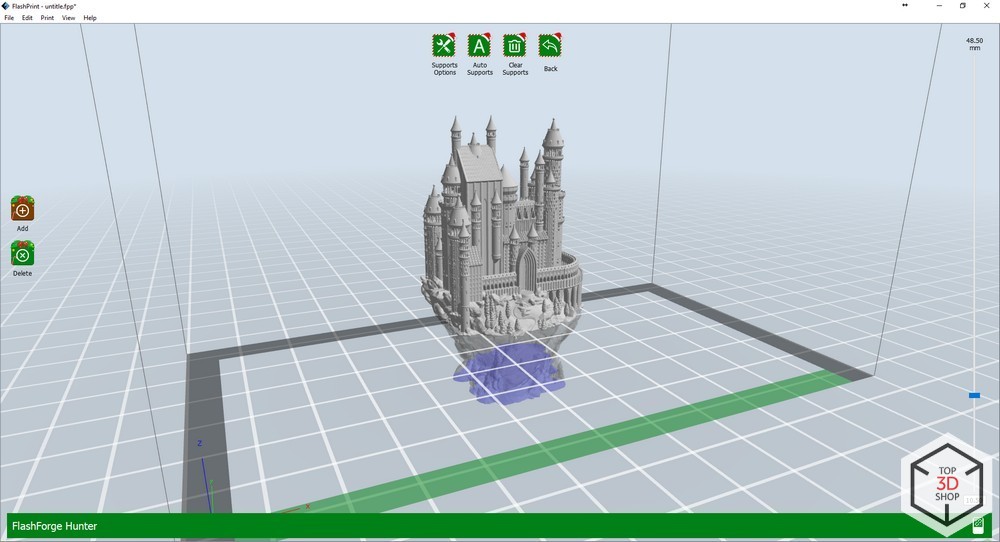

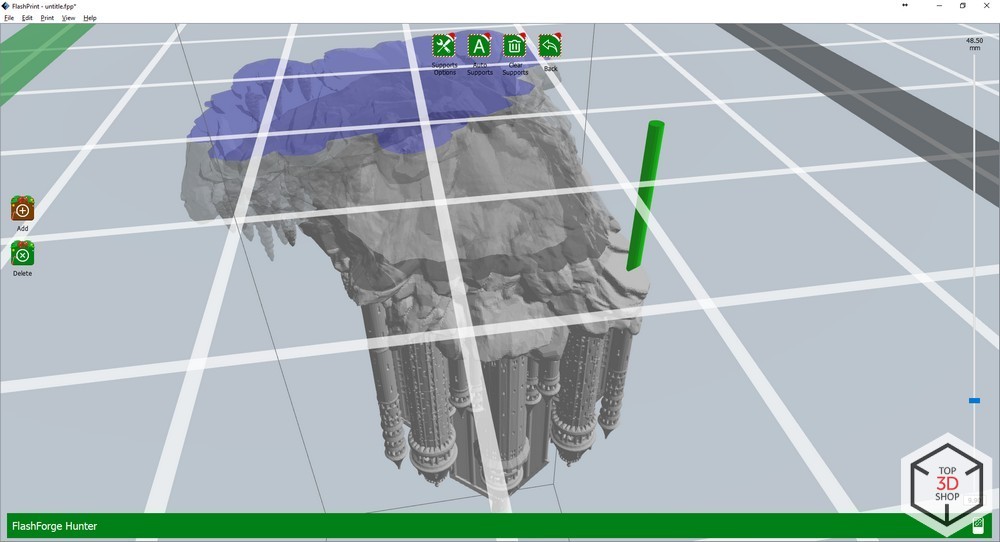

In the support mode, we can immediately see the section scale on the right. It is very convenient to find all vertices in the section through it, to add the necessary support in manual mode.

So, with closest consideration, we can find out that our model is hollow. We visually see the thickness of the walls and can track the exact location of the peaks.

Each vertex requires support when building.

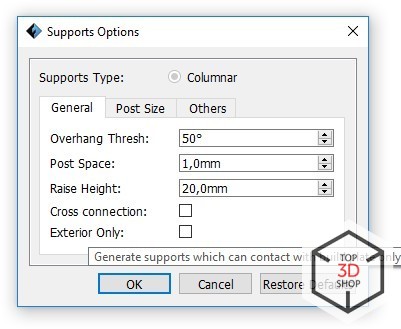

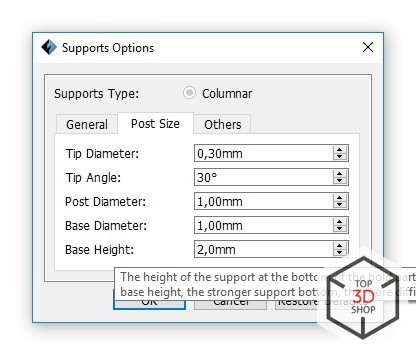

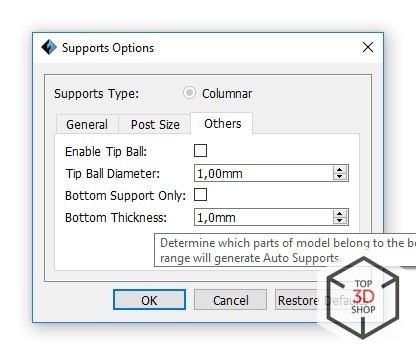

Supports are configured in a wide range.

From the angle of inclination of the model and the thickness of the supports, to the thickness and type of contact patch.

When you hover the mouse over each function, you will receive a description in English.

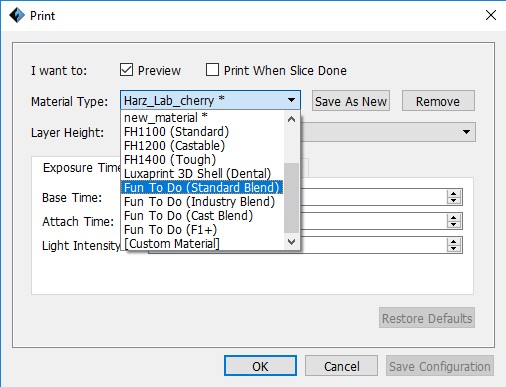

Slicing Menu Allows you to select predefined profiles and add your own. Very pleased with the availability of settings for the popular polymer Fun To Do.

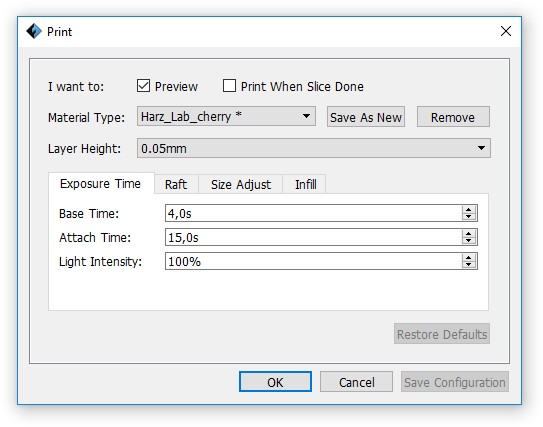

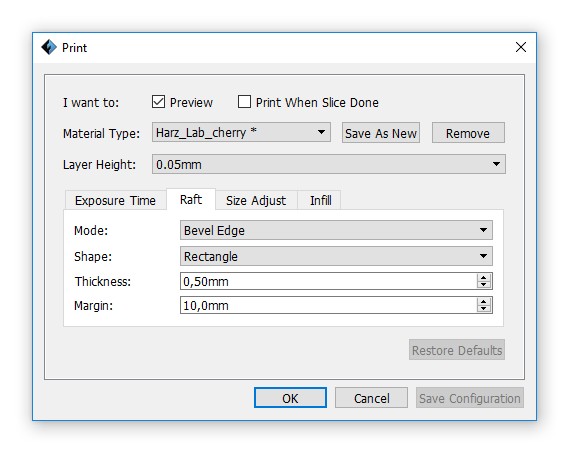

You can set the exposure time, size, shape and thickness of the raft and many other parameters.

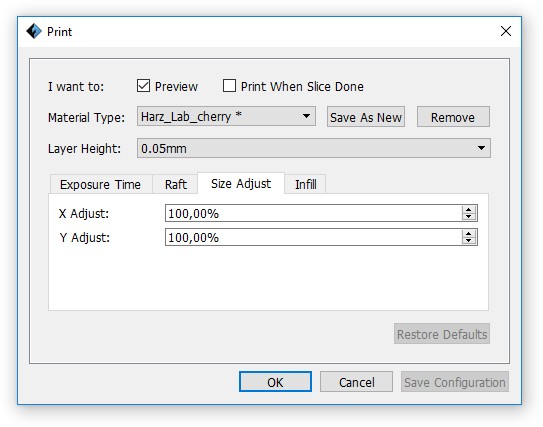

Using the settings, you can rescale the object.

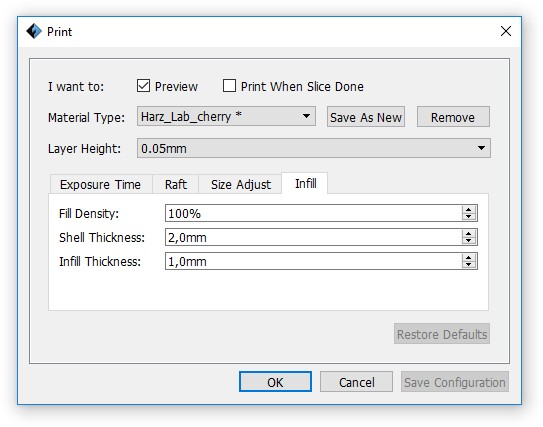

And also to set the degree of filling and even make the model hollow, which will facilitate it and save the polymer.

Printing process

The printing process is no different from most photopolymer 3D printers.

There are no additional valves in the printer, as in Creator B9 and Form. Sticking occurs due to the deformation of the film.

Illumination is uniform throughout the area. Diode projector is able to change its intensity of illumination without losing the lifetime of the projector. There is no agitator in the printer, so try not to leave the polymer for a week in the bath unattended, and if left, you need to mix it with a soft brush.

Service

All maintenance of the FlashForge Hunter 3D printer comes down to topping up the polymer and replacing the film on the bath. Thin film instead of thick glass that serves as the bottom of the bath is a good move towards improving print quality, but not the best in terms of service.

This film is the only thing that can cause difficulties. The replacement procedure requires accuracy and some skill. An improperly stretched film frowns and prevents the printer from operating normally.

In addition, it can lead to leakage of the photopolymer inside the printer. And to clean it from there is still a pleasure.

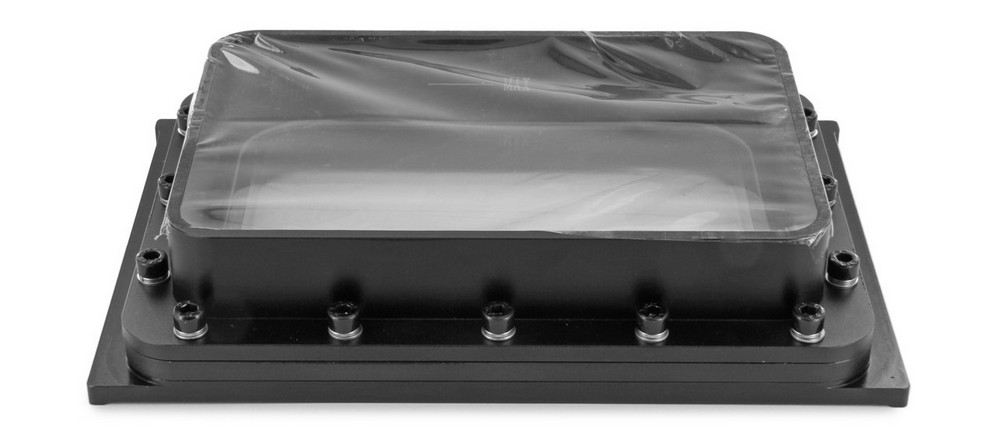

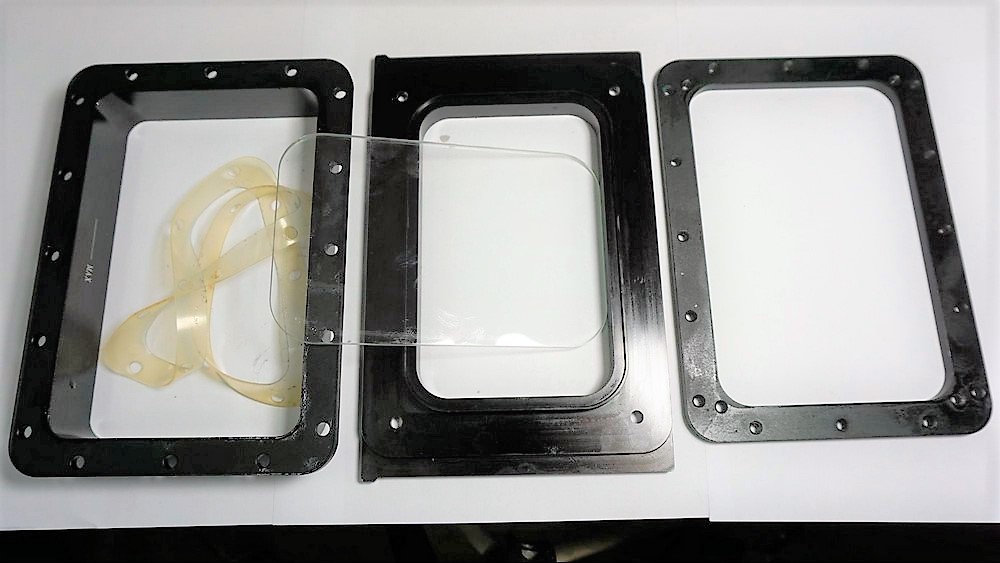

The bathroom consists of three fixing plates connected by screws, glass and film. You can not be afraid to break the thread, the quality of the metal at the highest level, but the principle of film replacement, to put it mildly, is inconvenient.

In case of improper assembly, due to which the film will receive an uneven tension, it can be stretched or torn during the first printing.

Film replacement

Turn off the main screws.

Disconnect the plate.

Remove the old film and throw it to the damn grandmother!

Remove the glass from the bottom plate. It is not fixed properly, but it can stick due to the frozen polymer.

My all the elements. Putting the first “sandwich”.

Turn over, tighten the main screws.

Next, take the second “sandwich”, in the grooves set the glass.

We connect all together. The glass at the same time presses the film.

Important: if the top plates are installed unevenly and the film sticks to the glass, then when fixing the plates, the film may overly stretch in one place and remain weakened in the other, which will lead to premature film aging, and even to a breakthrough.

Carefully overturn and tighten the tensioning screws that stretch the film.

Done! We are inimitable and finally replaced this damned film!

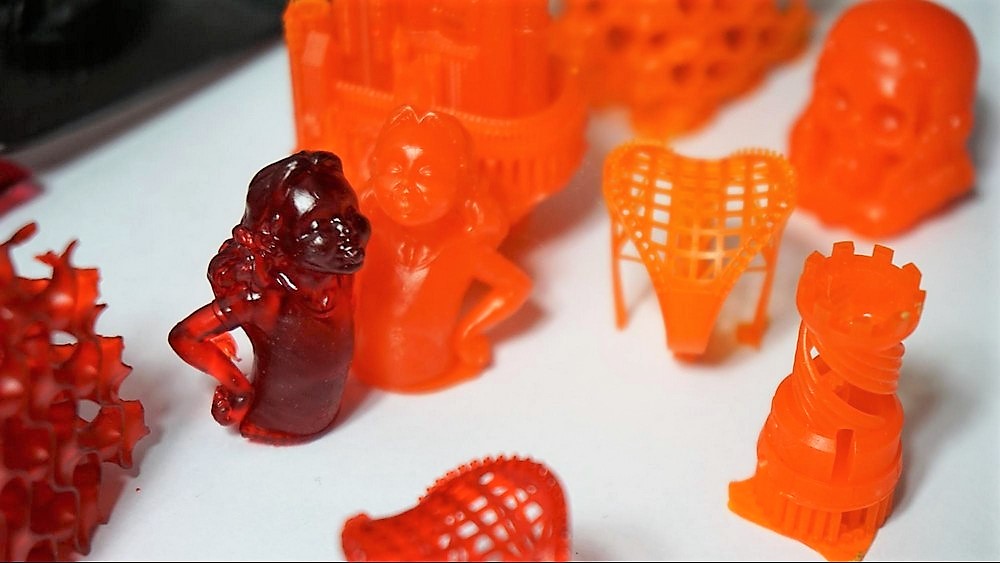

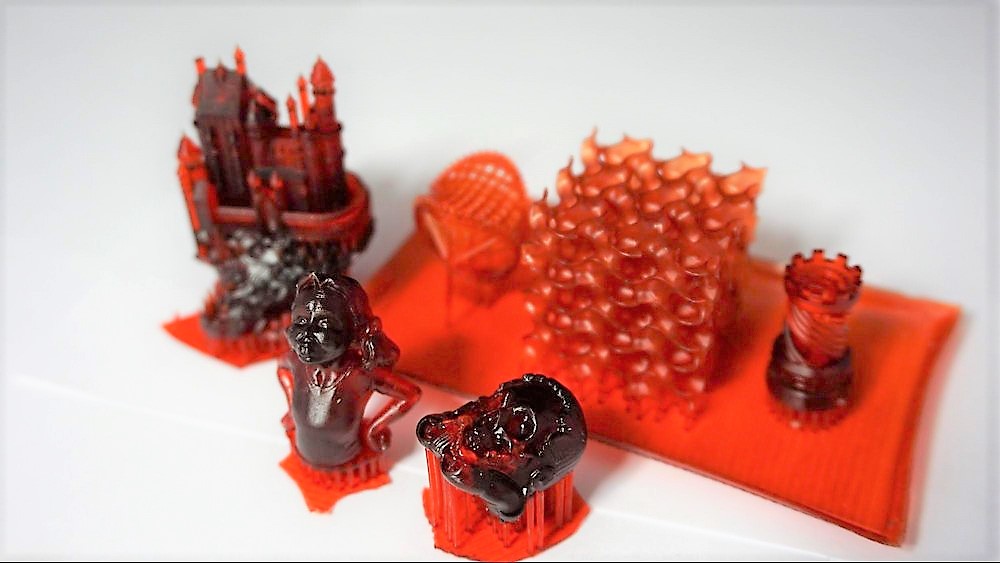

Materials

For testing FlashForge, we used photopolymer resins from different manufacturers.

FlashForge FH1100 Snatdart

Standard photopolymer supplied with the printer. Designed for prototyping.

NextDent C & B

Dental photopolymer for 3D printing of temporary bridges and crowns.

Fun to Do Standart Blend Black

Standard polymer for prototyping and modeling

Harz Labs Model

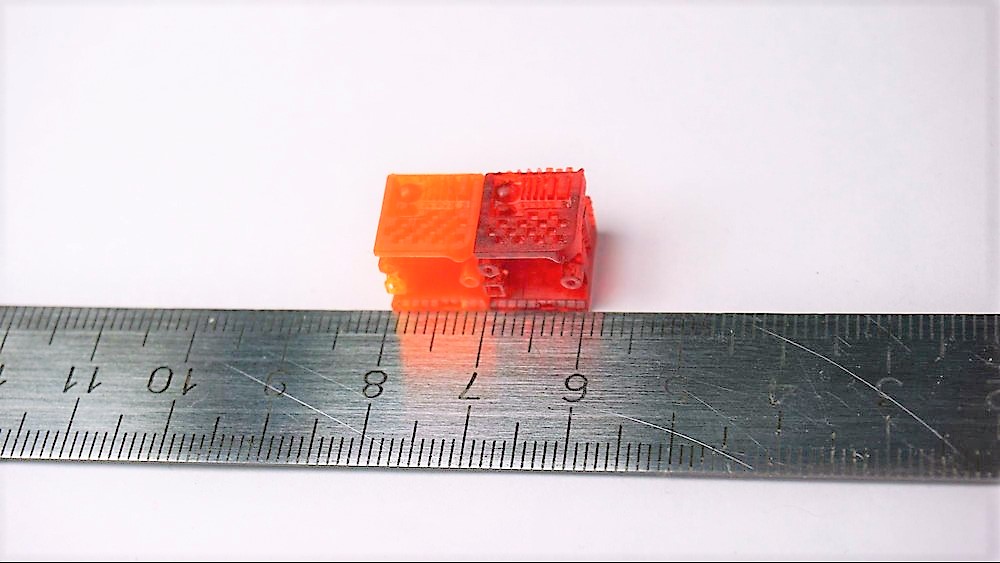

Photopolymer Harz Labs Model Available in orange, black, white, blue and transparent.

UVRes M001 Red and M111 Orange

Photopolymers UvRes M001 and M111 are designed for printing models for various purposes.

3Dsla “Oh, everything!” Red

“Oh, everything!” Is used for fast 3D printing.

Print quality with all tested materials is high, visually indistinguishable.

It was more convenient and easiest to work with Fun To Do, since the settings for these polymers were originally in the slicer.

Soon we will release a separate review on the testing of domestic photopolymers for stereolithographic 3D printing, there we will analyze their properties in more detail. Do not miss!

Advantages and disadvantages

The 3D printer showed itself diametrically on both sides. On the one hand - the undoubted advantages.

1. High quality print

2. Autofocus

3. Detailed customizable slicer

4. Rigid construction

5. Convenient fastening of the cover

And Hunter looks original. Whether it can be seriously attributed to the pluses is a matter of taste.

On the other hand - one minus. A peculiar and inconvenient system of replacing a bathroom film can frighten inexperienced users and lead to contamination of the printer. Tearing the film and filling the printer with photopolymer is not the most pleasing prospect.

Total

Unlike many photopolymer printers, FlashForge Hunter has a number of excellent features that provide a decent level of print quality.

If it were not so inconvenient to replace the film and the danger of its rupture, this printer could be called the best stereolithograph in its class.

Despite the difficulties with the bath, we were pleased with the printer. Print quality, usability and the ability to use most photopolymers on the market are worth it to cope with this.

We can recommend FlashForge Hunter as a decent and well-made machine with excellent print quality, which will become a loyal assistant to both the modeller and the homemade artist, as well as the professional jeweler or engineer.

Buy FlashForge Hunter 3D printer at Top3DShop.ru and get free shipping and training. We also remind you that when you buy a 3D printer in Top 3D Shop you get a lifetime discount on consumables up to 20%.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/409663/