DIY controller LED panel on CPLD using BAM modulation Some time ago, I participated in the discussion of the DIY project of a matrix LED clock.

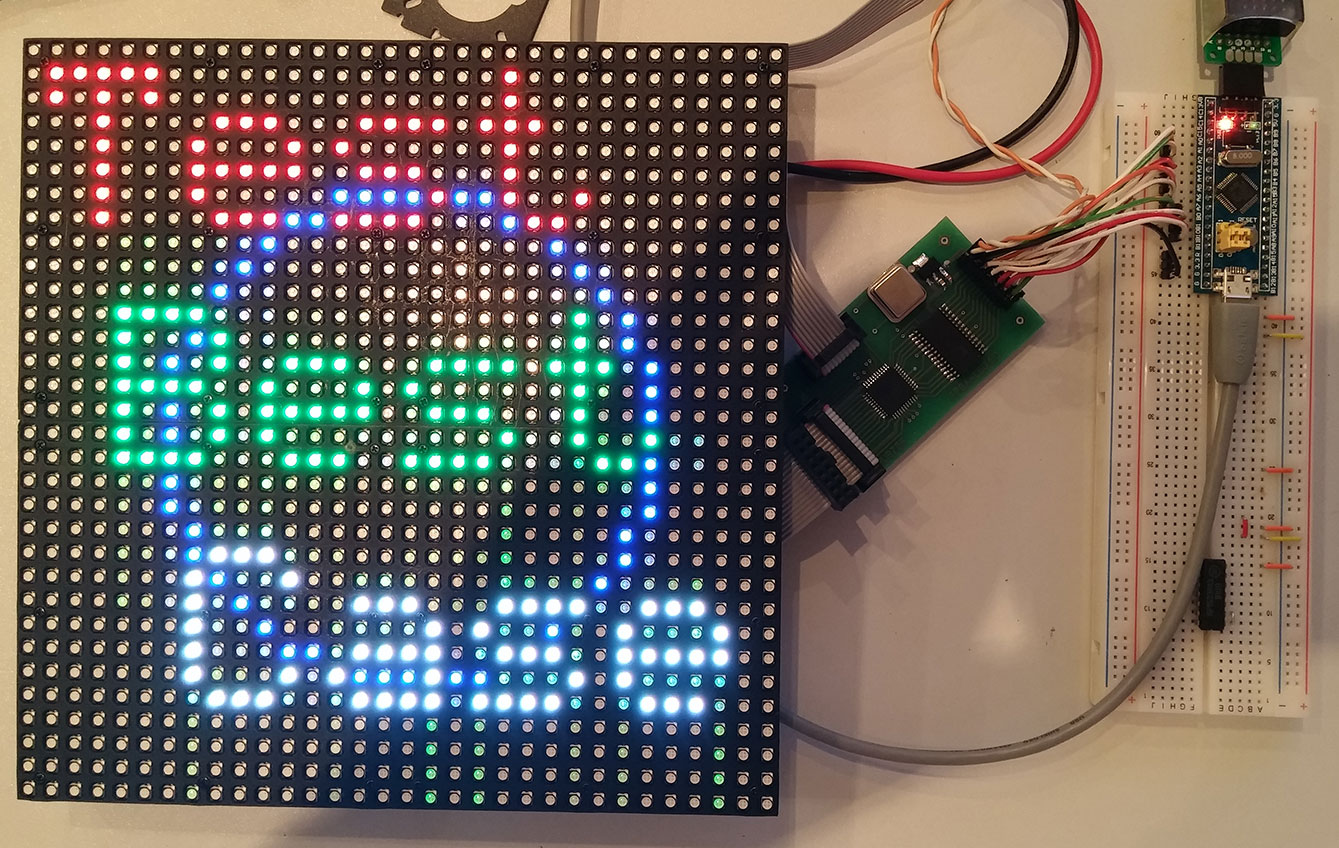

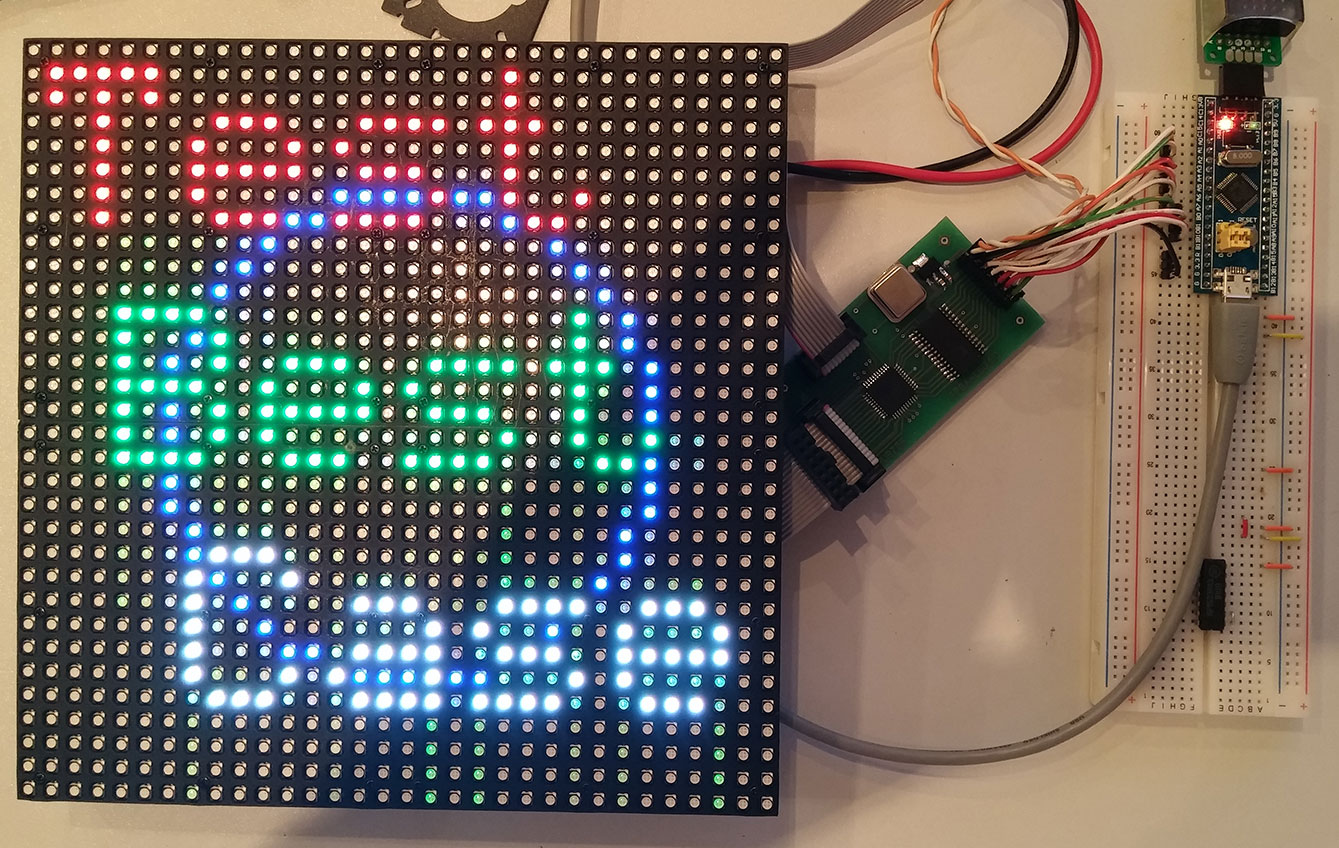

And what surprised me was that the ancient monochrome 8x8 LED matrixes were used as a display device in increments of 5 millimeters. Moreover, complex printed circuit boards were divorced under them, and software dynamic display was made. And this is at a time when ready-made full-color LED panels 64x32 in 3 mm increments are available at a price of around $ 10-20 a long time ago. And the total range of such panels is very large and has a pixel pitch from 2 to 10 mm and almost any size.

At the same time, it is rather difficult to use such panels in DIY constructions - ready controllers cost quite a lot of money and do not have a normal API. It’s quite difficult to do quite a quick scan of the panel on microcontrollers commonly used in DIY. Moreover, time intervals must be maintained with high accuracy - otherwise a noticeable unevenness of brightness begins.

There are some good solutions at

Adafruit , but they are all quite expensive and complicated.

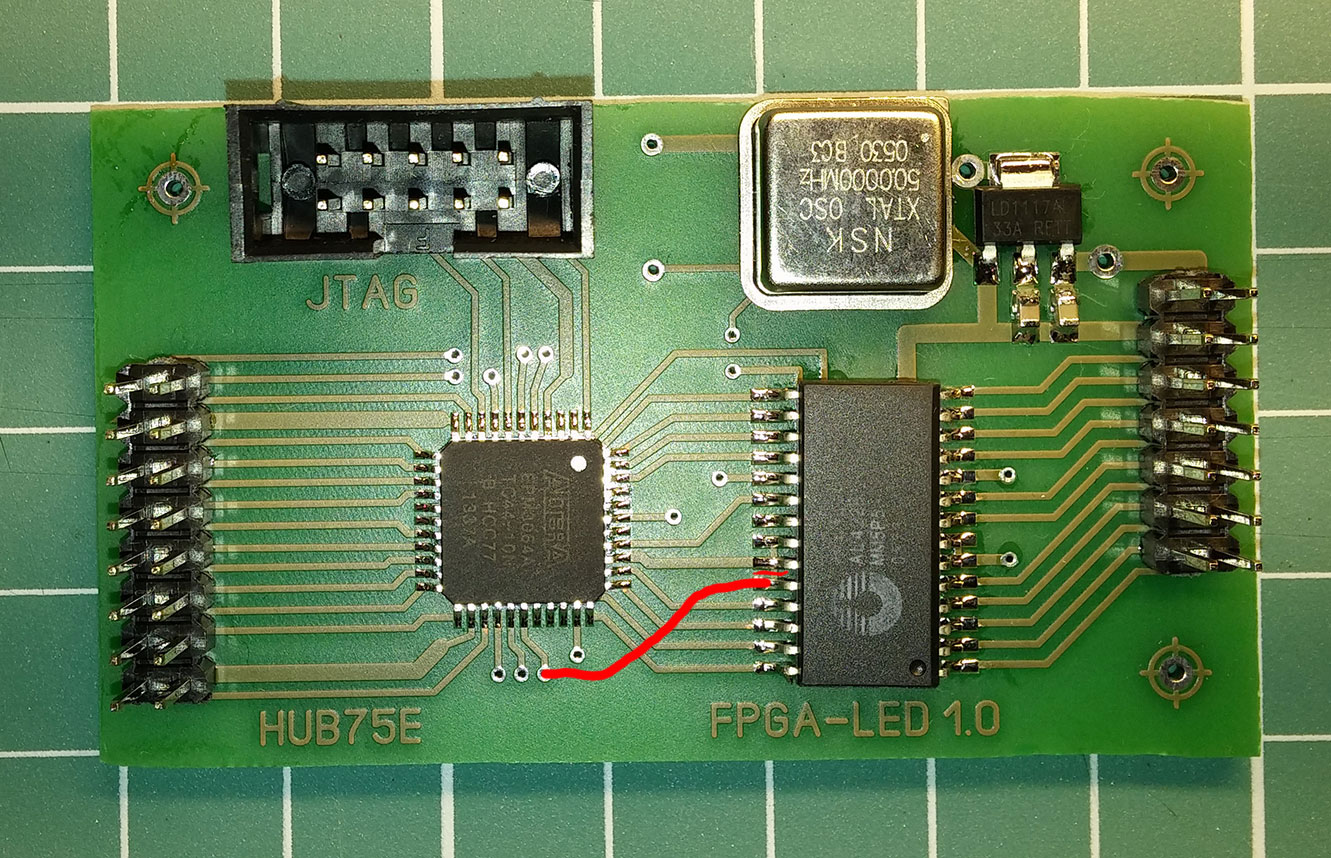

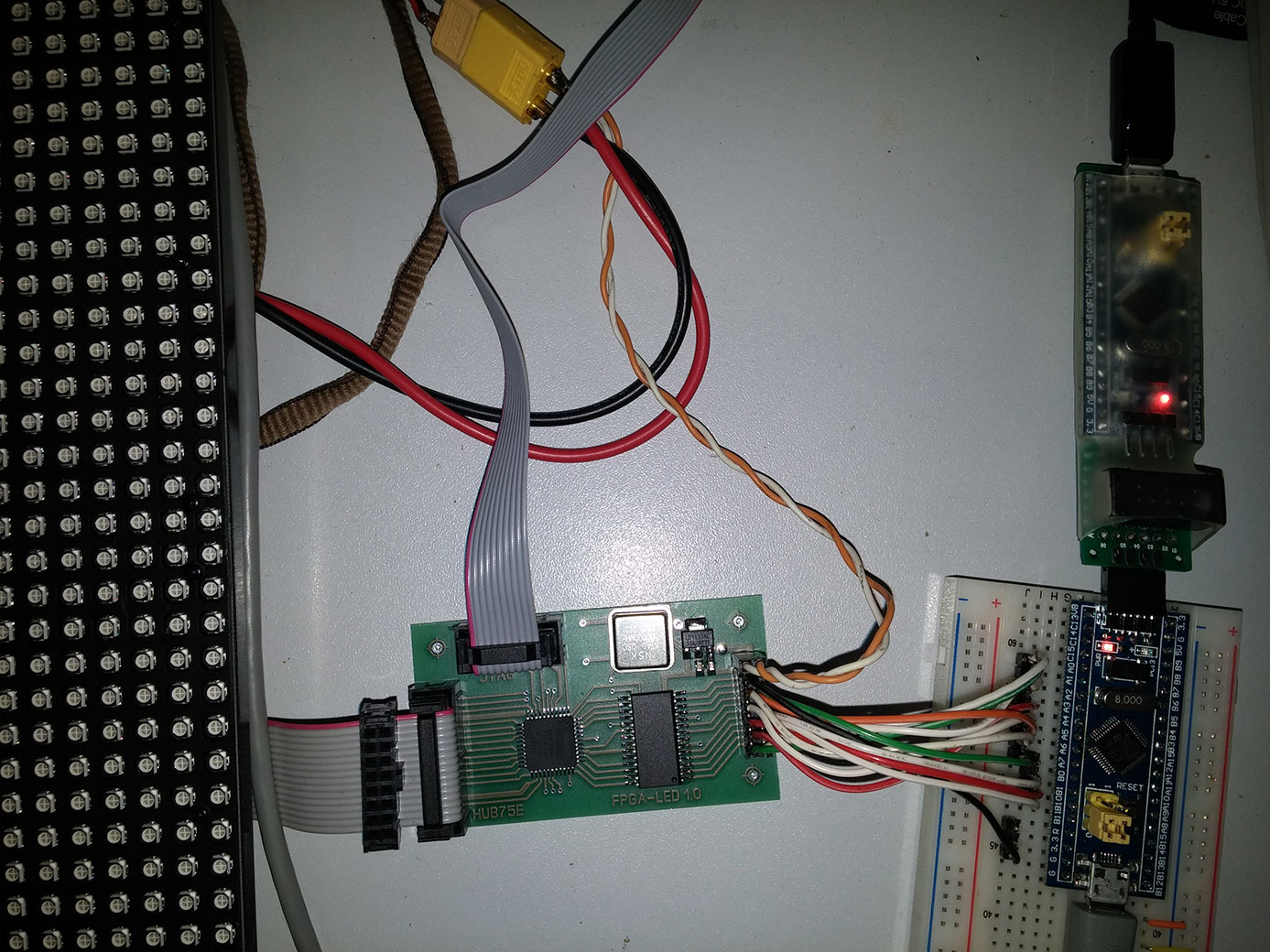

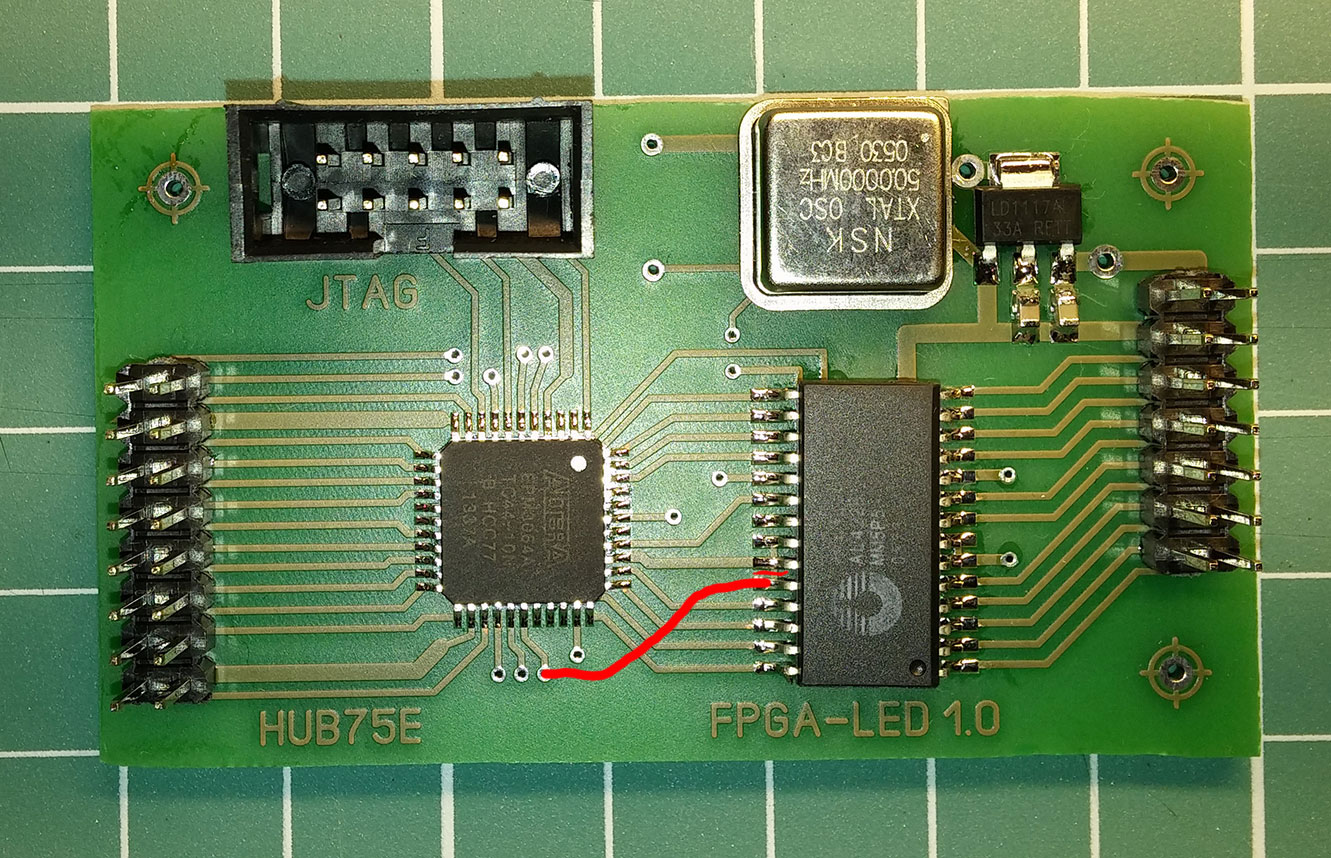

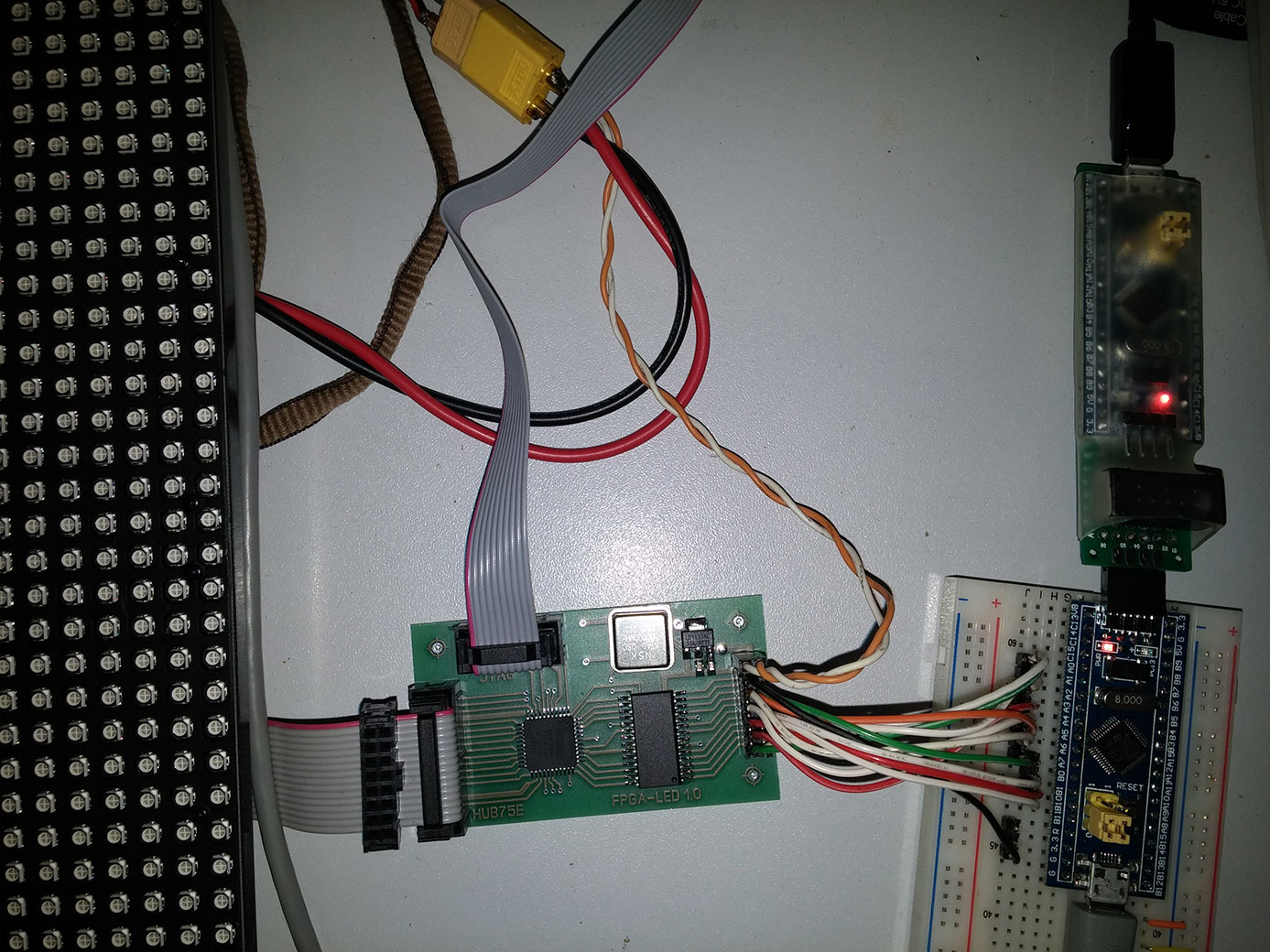

After some thought, the thought arose - why not make an extremely inexpensive board that would be a bridge between a regular penny type Arduino board and a LED panel? After a couple of months, the fussing was born.

This article describes the second, improved version of the controller.