Why photo reporter 3D printer

Hello! We share our case study on using the Raise3D N2 3D printer by our client - the photo workshop Photmas.

Working in professional photojournalism for over 20 years, we know that modern standards for the work of a photo reporter place high demands on the speed of transferring materials to the editor and on the variety of survey points. These problems can be solved with the help of modern technologies and additional equipment that helps to install and control cameras in places inaccessible to the photographer. However, there are many niches in the market for accessories that have helped to solve these problems. Most often, photographers design such things on their own, and they do not go beyond the framework of "homemade". We decided to take this problem seriously and concentrated on the development, design and production of accessories that facilitate and simplify work with remote cameras.

Our photo workshop Photmas.ru was born gradually. It all started with a large project - developing a DKV identikit, with which you can mount the camera in almost any inaccessible place, control it from a distance, receive broadcast from the viewfinder and the photos themselves to a remote computer online. At present, the robot has already been successfully tested at many major sporting events, two copies bought a large news agency.

Installation of the identikit DKV on VTB Ice Palace in Legends Park

Installation of the identikit DKV at the Arena Otkrytie (Spartak Stadium)

Developing the first version of the DKV identikit, we ordered the production of all the parts on the side. But it was a long and expensive way. All parts are test and trial - they are constantly being modified, and during production at an outsourcing, you have to pay for the part made, even if by the time it is manufactured (and it can take up to a week) it is already clear that it will not be like that. It became obvious that you need to buy your own equipment. At that time - 3 years ago, 3D printers were already on the market, but the market itself was not quite mature. Therefore, we decided to postpone the printer and first bought a router.

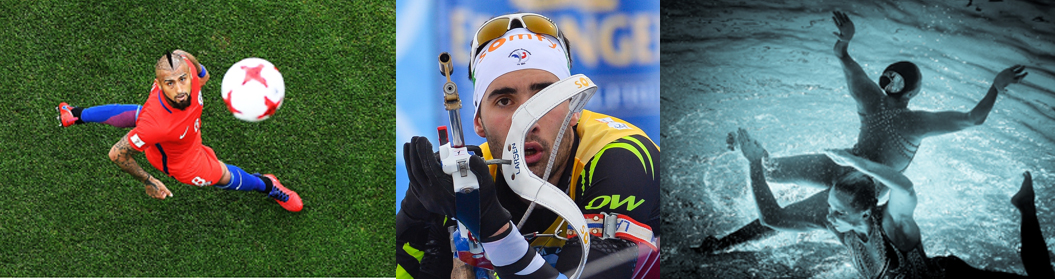

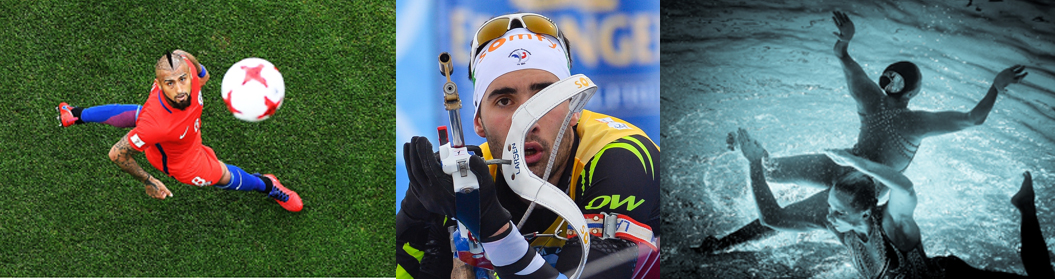

Photos taken using equipment made by the Photmas photo workshop

Gradually, we also had other developments - equipment that facilitates the work of a news photographer in remote cameras (buttons and remote control pedals, camera switches, ice hockey boxes, etc.). However, the milling machine cannot replace all the ways of creating parts; moreover, often we only needed test prototypes that are not rational and sometimes impossible to grind on the mill. Fraser is noisy, dirty, any change in details requires adjustment of the control program, and this time. The classic struggle of additive against subtractive. In other words, what is easier and faster is to cut or stick. And I had to go back to the idea of buying a printer.

Photmas.ru workshop equipment: Raise 3D N2 printer, CNC milling machine, thermal designer (device for bending plastic).

The printer was chosen for a long time. For us, it was very important to have a stable print quality, the presence of two nozzles, which allow printing complex parts with soluble supports, a closed chamber, for printing with abs plastic and a large desktop size. We chose from several models - we considered both Chinese and Russian manufacturers. However, in the end, they chose Raise3D . In addition to the announced functionality, reliability and price, quality and friendly technical support was also important for us - we chose not only the brand, but also the supplier, hoping to find a good partner for the future.

A device for controlling DKV Fire remout and its installation during the Confederation Cup 2017.

When the printer appeared in our workshop - which was previously a harsh male den, where aluminum was milled, sawed and plexiglas bent, we even felt somehow embarrassed - as far as it was met with its metrosexuality, style and glamor. However, looking ahead, we will say that in difficult and rather dusty conditions of the neighborhood with a router and a circular printer, the printer has no problems.

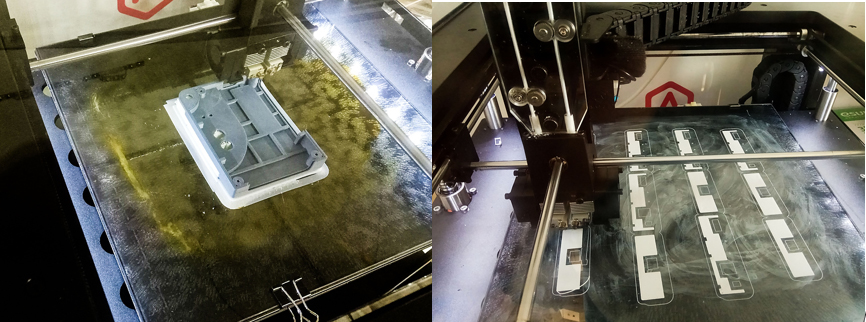

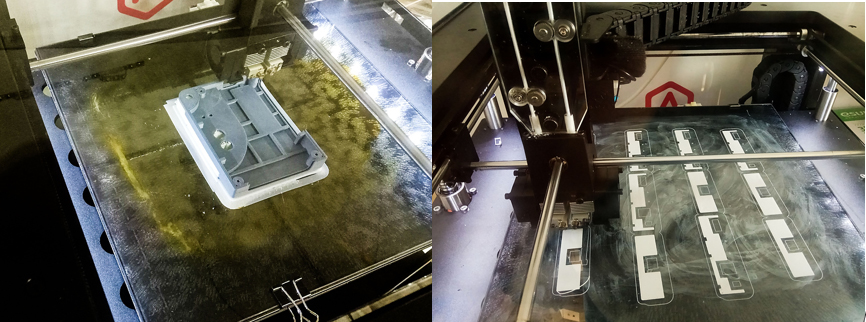

Printing DKV-Fire Device Body Parts

The software ideaMaker for MAC, which comes with Raise3D, was not difficult to master - control through Wi-Fi, presets, auto updates, visible print areas ... against the backdrop of brutal, like a MACH3 bootstrap with self-written G-code scripts on the screen with lower SVGA resolution, all of the above seemed like a cosmic achievement.

However, the devil is kept in the details - in our case, the heated table became this important detail: first (sorry for the pun) these very details stuck to it simply tightly. And we were glad that they stick so well here - usually the problem is that everything is sticking out ... However, we soon realized that you just need to cool the surface and the part can be easily removed. But as soon as we figured it out, the real problems with sticking started. We tried a huge number of solutions and techniques (such “dances with a tambourine”): sugar solution, kvass, and different types of beer. In the end they came to abs-juice - a solution of abs plastic in acetone. On what we live the last six months.

DKV Flash camera remote shutter button and HC Dynamo Moscow Moscow photojournalist Sergey Babunov, who equipped his camera with a button.

Print quality is good. We make the corps of our products on it, for example, the DKV-FLASH release buttons or the DKV-FIRE remout control device. The buttons are small - and they can be printed at once by 5-6 pieces, but Fire is more complex objects. It takes more than a day to print all the details of 1 case. This summer we had a large order for this product - and it was necessary to make it in a short time. Every day, after working in Moscow, we had to come to the workshop in the Moscow region, put a printer on the seal, go to bed, remove a part in the morning and install a new print before going to work. In this almost continuous mode, the printer worked for almost 2 weeks - the quality was consistently good.

Video camera for the DKV robot, which translates the image from the camera viewfinder. 5 details printed on Raise 3d, adjustable retractable lens hood to protect the lens.

I must say that Raise3D is quite friendly with its customers. The head office released the firmware with the support of the Russian language (although Pushkin’s language is, as usual, 30% longer than the Byron language, and some of the inscriptions on the buttons and the menu turned out to be abbreviations in the spirit of the novelty of the 1920s), however, a few comments and suggestions were made by us on the forum support has been accounted for.

The “Color World” is also very operational - “cartridges” in the form of plastic or spare parts are delivered thanks to a successful geography in just a few hours.

During the operation there were 2 serious breakdowns, but thanks to the CM, it was simple in each case for a couple of hours.

The first time the limit switch broke. Most likely it was a marriage. He just collapsed and the printer, not finding the limit switch, began to peck with an extruder and nozzles on the model and the wall. Fortunately, it was noticed immediately and it was de-energized. The repair, that is, the replacement of the scarves with the switch off, took the notorious couple of hours and the work resumed.

The second problem arose after night printing - a blockage of the right nozzle with HIPS support. Attempting to clean with the standard methods described in the user manual and on the support site did not help, and when disassembling for washing (supposed to be washed by Lemonen), the nozzle broke - so much it coked and stuck. And again the delivery of spare parts took only a couple of hours.

As already mentioned, printing is mainly ABS plastic with HIPS support. All ESUN Materials. There were practically no problems with the thread. Printing is either directly on the glass with ABS-juice, or on the raft, if you need a fraction of roughness on this side. Models with a layer thickness of 0.1 look and feel tactile, of course, much more pleasant, but the print time increases significantly compared to 0.25, so the usual print mode is still 0.25.

Another pair of nuances. Plastic from a freshly coil can overwhelm around the shafts on which the reels hang. The G-code of the program start can be corrected so that the nozzles do not try to cling to the clips that secure the glass. This is in theory. We did not do this, save time and just move the leftmost clip to the right.)

Aligning the nozzles to Z is convenient to do not only with the caliber that comes with the printer, but more accurately and with the help of cigarette foil - the way traditional for the router and its smoking operator.

In the depths of the FAK on the English site, a manual for calibrating nozzles on X and U is hidden. You only need to search, and it will be found.

And, perhaps, the main problem with the printer is to calculate timing. What kind of things to put on the stamp at night, so that at the right moment before leaving for work the stamp is over. Well, or on arrival it was possible to immediately put the next detail. Fortunately, the internal software timers work correctly.

In general, Raise3D abounds with features. Its price niche is a buyer of advanced or expert level, requiring reliability, stability and large volume, combined with almost the maximum quality for this class of printers. Therefore, the above and other nuances will not become a big problem. Thanks to its powerful shafts and solid construction, it’s a machine, a terminator. That is, the resource of use is great. But thanks to the LCD display, excellent software, Wi-Fi, he is glamorous enough to decorate the office of a large campaign, and to impress the client. At the same time, nothing prevents to put it at home. He is not noisy, sleep in the next room so-called. Home office is absolutely real, especially if you disable the Z-hop function and print the model without support. And “otkolupyvanie” in the morning printed samples can be a favorite entertainment for young households and pets))).

The text is provided by the photo workshop www.photmas.ru and www.dkvis.ru .

Join us in the social. networks to keep abreast of the latest developments:

VKontakte Raise3D Club Russia - Raise3D Owners Club in Russia

VKontakte | Facebook | YouTube

The team of the company Color World

Working in professional photojournalism for over 20 years, we know that modern standards for the work of a photo reporter place high demands on the speed of transferring materials to the editor and on the variety of survey points. These problems can be solved with the help of modern technologies and additional equipment that helps to install and control cameras in places inaccessible to the photographer. However, there are many niches in the market for accessories that have helped to solve these problems. Most often, photographers design such things on their own, and they do not go beyond the framework of "homemade". We decided to take this problem seriously and concentrated on the development, design and production of accessories that facilitate and simplify work with remote cameras.

Our photo workshop Photmas.ru was born gradually. It all started with a large project - developing a DKV identikit, with which you can mount the camera in almost any inaccessible place, control it from a distance, receive broadcast from the viewfinder and the photos themselves to a remote computer online. At present, the robot has already been successfully tested at many major sporting events, two copies bought a large news agency.

Installation of the identikit DKV on VTB Ice Palace in Legends Park

Installation of the identikit DKV at the Arena Otkrytie (Spartak Stadium)

Developing the first version of the DKV identikit, we ordered the production of all the parts on the side. But it was a long and expensive way. All parts are test and trial - they are constantly being modified, and during production at an outsourcing, you have to pay for the part made, even if by the time it is manufactured (and it can take up to a week) it is already clear that it will not be like that. It became obvious that you need to buy your own equipment. At that time - 3 years ago, 3D printers were already on the market, but the market itself was not quite mature. Therefore, we decided to postpone the printer and first bought a router.

Photos taken using equipment made by the Photmas photo workshop

Gradually, we also had other developments - equipment that facilitates the work of a news photographer in remote cameras (buttons and remote control pedals, camera switches, ice hockey boxes, etc.). However, the milling machine cannot replace all the ways of creating parts; moreover, often we only needed test prototypes that are not rational and sometimes impossible to grind on the mill. Fraser is noisy, dirty, any change in details requires adjustment of the control program, and this time. The classic struggle of additive against subtractive. In other words, what is easier and faster is to cut or stick. And I had to go back to the idea of buying a printer.

Photmas.ru workshop equipment: Raise 3D N2 printer, CNC milling machine, thermal designer (device for bending plastic).

The printer was chosen for a long time. For us, it was very important to have a stable print quality, the presence of two nozzles, which allow printing complex parts with soluble supports, a closed chamber, for printing with abs plastic and a large desktop size. We chose from several models - we considered both Chinese and Russian manufacturers. However, in the end, they chose Raise3D . In addition to the announced functionality, reliability and price, quality and friendly technical support was also important for us - we chose not only the brand, but also the supplier, hoping to find a good partner for the future.

A device for controlling DKV Fire remout and its installation during the Confederation Cup 2017.

When the printer appeared in our workshop - which was previously a harsh male den, where aluminum was milled, sawed and plexiglas bent, we even felt somehow embarrassed - as far as it was met with its metrosexuality, style and glamor. However, looking ahead, we will say that in difficult and rather dusty conditions of the neighborhood with a router and a circular printer, the printer has no problems.

Printing DKV-Fire Device Body Parts

The software ideaMaker for MAC, which comes with Raise3D, was not difficult to master - control through Wi-Fi, presets, auto updates, visible print areas ... against the backdrop of brutal, like a MACH3 bootstrap with self-written G-code scripts on the screen with lower SVGA resolution, all of the above seemed like a cosmic achievement.

However, the devil is kept in the details - in our case, the heated table became this important detail: first (sorry for the pun) these very details stuck to it simply tightly. And we were glad that they stick so well here - usually the problem is that everything is sticking out ... However, we soon realized that you just need to cool the surface and the part can be easily removed. But as soon as we figured it out, the real problems with sticking started. We tried a huge number of solutions and techniques (such “dances with a tambourine”): sugar solution, kvass, and different types of beer. In the end they came to abs-juice - a solution of abs plastic in acetone. On what we live the last six months.

DKV Flash camera remote shutter button and HC Dynamo Moscow Moscow photojournalist Sergey Babunov, who equipped his camera with a button.

Print quality is good. We make the corps of our products on it, for example, the DKV-FLASH release buttons or the DKV-FIRE remout control device. The buttons are small - and they can be printed at once by 5-6 pieces, but Fire is more complex objects. It takes more than a day to print all the details of 1 case. This summer we had a large order for this product - and it was necessary to make it in a short time. Every day, after working in Moscow, we had to come to the workshop in the Moscow region, put a printer on the seal, go to bed, remove a part in the morning and install a new print before going to work. In this almost continuous mode, the printer worked for almost 2 weeks - the quality was consistently good.

Video camera for the DKV robot, which translates the image from the camera viewfinder. 5 details printed on Raise 3d, adjustable retractable lens hood to protect the lens.

I must say that Raise3D is quite friendly with its customers. The head office released the firmware with the support of the Russian language (although Pushkin’s language is, as usual, 30% longer than the Byron language, and some of the inscriptions on the buttons and the menu turned out to be abbreviations in the spirit of the novelty of the 1920s), however, a few comments and suggestions were made by us on the forum support has been accounted for.

The “Color World” is also very operational - “cartridges” in the form of plastic or spare parts are delivered thanks to a successful geography in just a few hours.

During the operation there were 2 serious breakdowns, but thanks to the CM, it was simple in each case for a couple of hours.

The first time the limit switch broke. Most likely it was a marriage. He just collapsed and the printer, not finding the limit switch, began to peck with an extruder and nozzles on the model and the wall. Fortunately, it was noticed immediately and it was de-energized. The repair, that is, the replacement of the scarves with the switch off, took the notorious couple of hours and the work resumed.

The second problem arose after night printing - a blockage of the right nozzle with HIPS support. Attempting to clean with the standard methods described in the user manual and on the support site did not help, and when disassembling for washing (supposed to be washed by Lemonen), the nozzle broke - so much it coked and stuck. And again the delivery of spare parts took only a couple of hours.

As already mentioned, printing is mainly ABS plastic with HIPS support. All ESUN Materials. There were practically no problems with the thread. Printing is either directly on the glass with ABS-juice, or on the raft, if you need a fraction of roughness on this side. Models with a layer thickness of 0.1 look and feel tactile, of course, much more pleasant, but the print time increases significantly compared to 0.25, so the usual print mode is still 0.25.

Another pair of nuances. Plastic from a freshly coil can overwhelm around the shafts on which the reels hang. The G-code of the program start can be corrected so that the nozzles do not try to cling to the clips that secure the glass. This is in theory. We did not do this, save time and just move the leftmost clip to the right.)

Aligning the nozzles to Z is convenient to do not only with the caliber that comes with the printer, but more accurately and with the help of cigarette foil - the way traditional for the router and its smoking operator.

In the depths of the FAK on the English site, a manual for calibrating nozzles on X and U is hidden. You only need to search, and it will be found.

And, perhaps, the main problem with the printer is to calculate timing. What kind of things to put on the stamp at night, so that at the right moment before leaving for work the stamp is over. Well, or on arrival it was possible to immediately put the next detail. Fortunately, the internal software timers work correctly.

In general, Raise3D abounds with features. Its price niche is a buyer of advanced or expert level, requiring reliability, stability and large volume, combined with almost the maximum quality for this class of printers. Therefore, the above and other nuances will not become a big problem. Thanks to its powerful shafts and solid construction, it’s a machine, a terminator. That is, the resource of use is great. But thanks to the LCD display, excellent software, Wi-Fi, he is glamorous enough to decorate the office of a large campaign, and to impress the client. At the same time, nothing prevents to put it at home. He is not noisy, sleep in the next room so-called. Home office is absolutely real, especially if you disable the Z-hop function and print the model without support. And “otkolupyvanie” in the morning printed samples can be a favorite entertainment for young households and pets))).

The text is provided by the photo workshop www.photmas.ru and www.dkvis.ru .

Join us in the social. networks to keep abreast of the latest developments:

VKontakte Raise3D Club Russia - Raise3D Owners Club in Russia

VKontakte | Facebook | YouTube

The team of the company Color World

Source: https://habr.com/ru/post/409799/