[CASE] As we did the layout of the building Novo Nordisk

This is a story about how we made the layout of the building of the pharmaceutical company Novo Nordisk.

The popularity of 3D printing in architecture is growing. Architectural models are popular not only among developers and architects, many companies are not opposed to decorate the interior with 3D models of their buildings. This is one of these orders.

Order

The request from the client came from the already rendered renders of buildings, structures and infrastructure, with a general plan of the territory and several photos of the real object.

It was not possible to get the 3D models by which the renders were created, but it doesn’t matter - it’s much easier to work on your own models when creating a layout, creating them from scratch.

As it was done before

Before the advent of 3D printing and software-controlled machine tools, mock-ups were created manually from paper and foam plastic, which had its own characteristic flaws, such as low accuracy and production time.

How we did it

Project

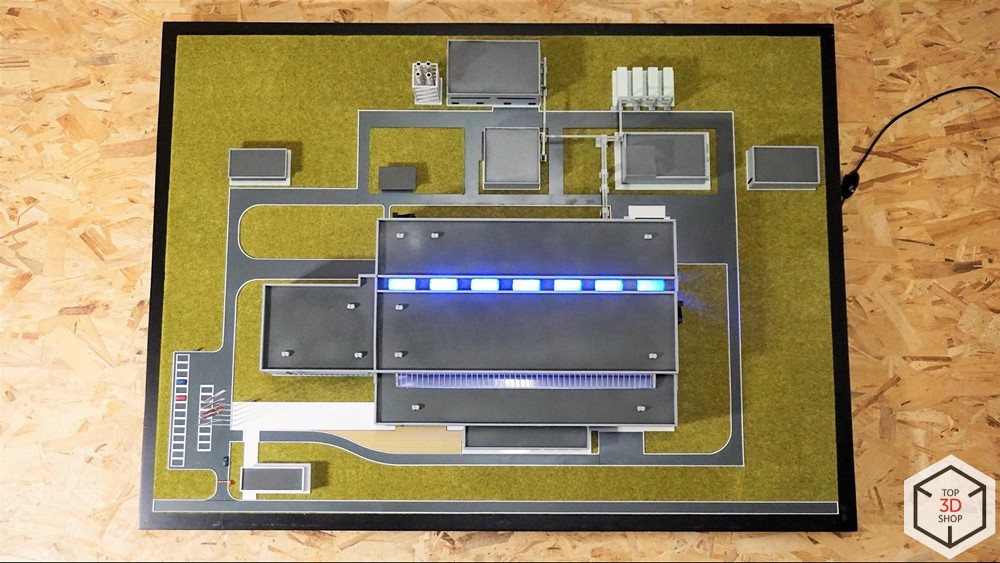

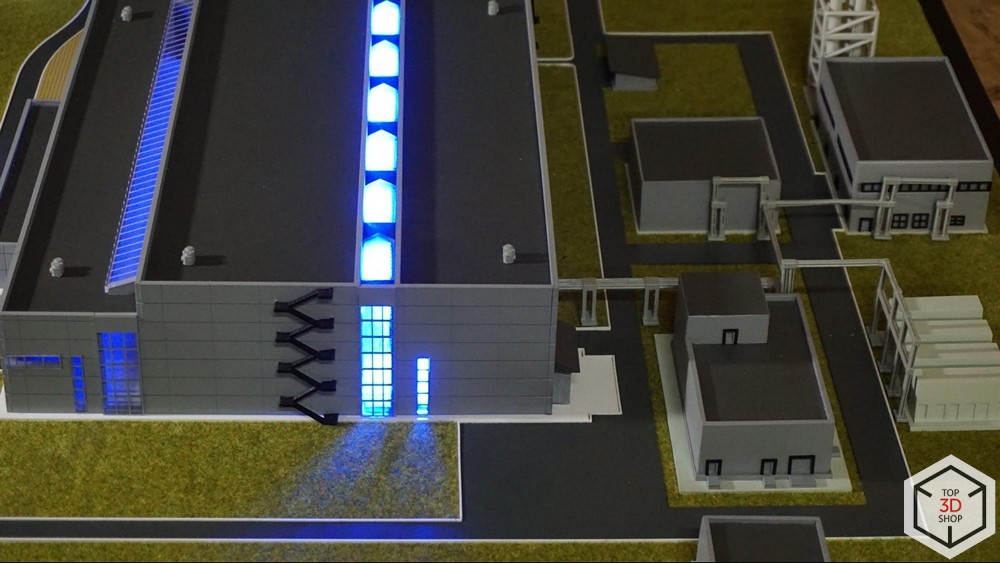

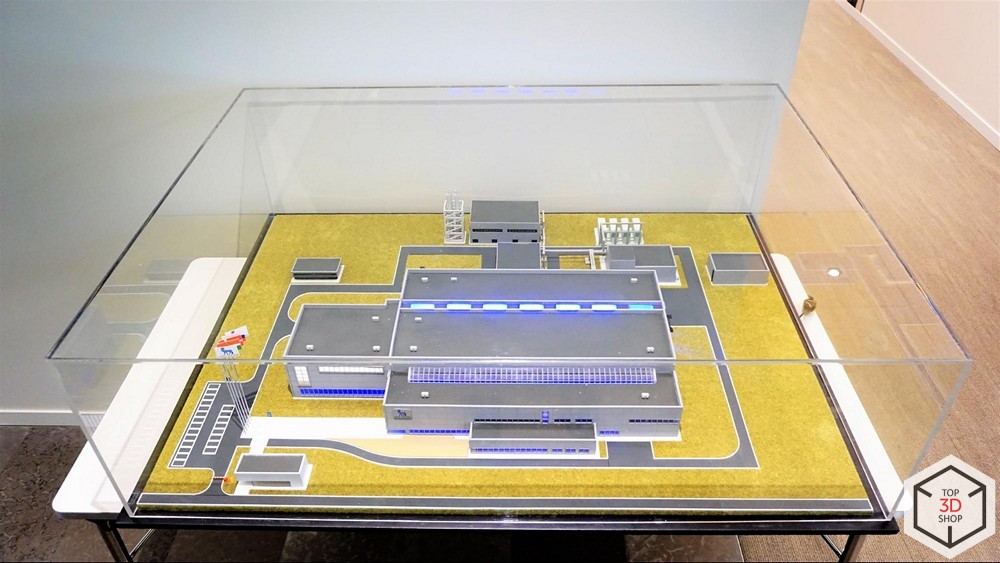

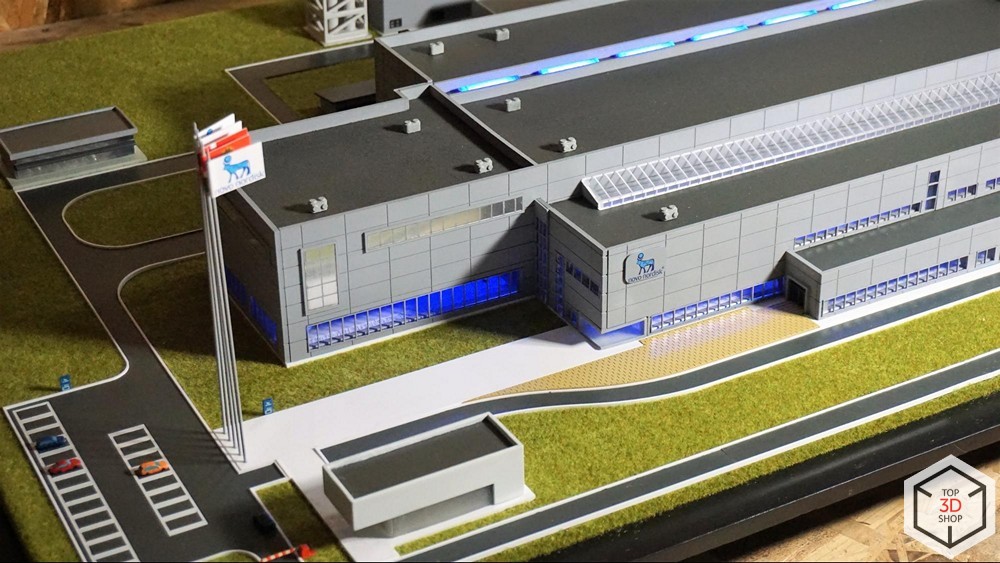

Since we only had a couple of photographs, renders and a BTI plan for a small part of the main building, the scale was selected for quite a long time, tried on. Did a few renders of the grounds. Compared with the original images. One of the customer's requirements was to place the layout on an area of no more than 1 sq. M. Everything was done. The total area of the make-up bin was 0.97 sq.m.

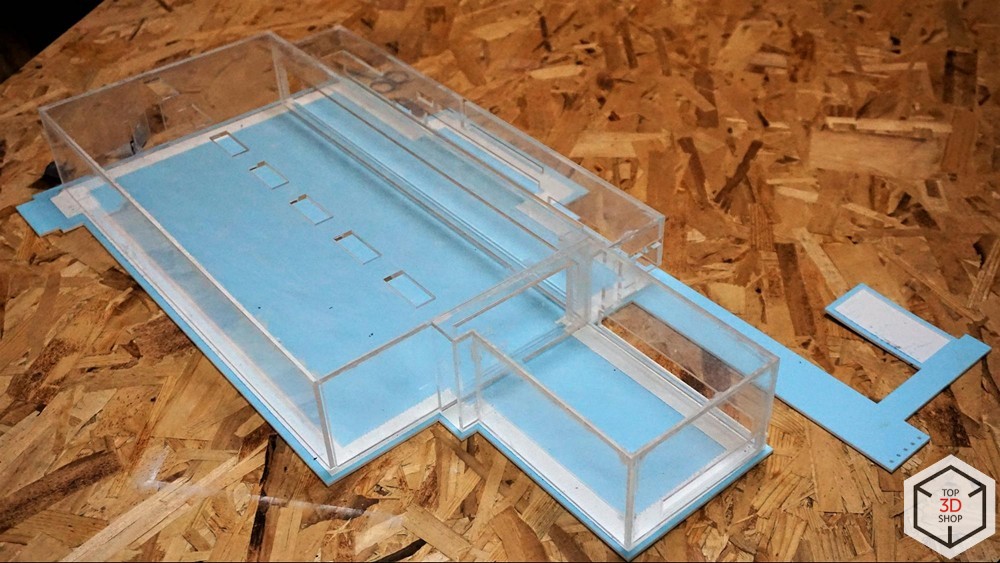

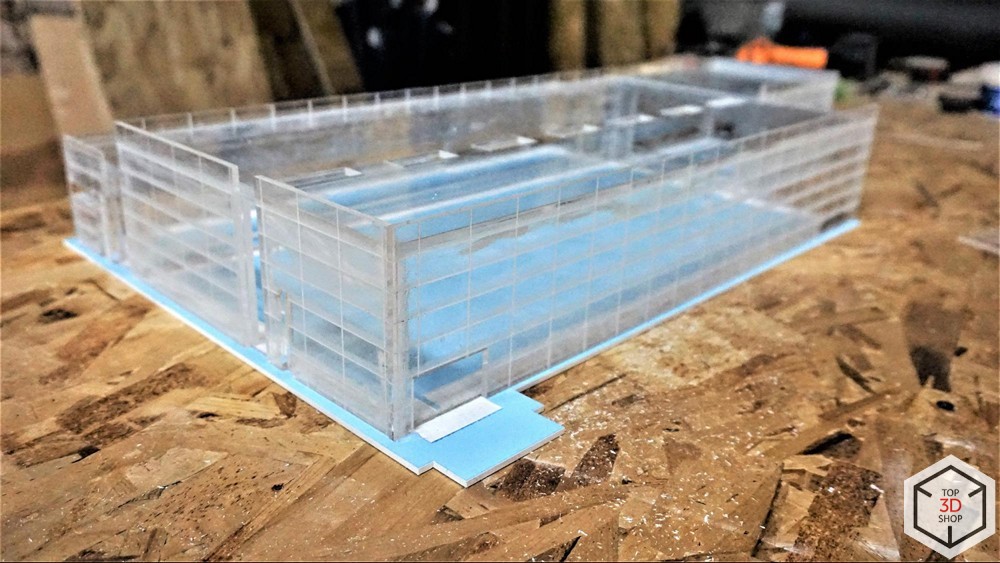

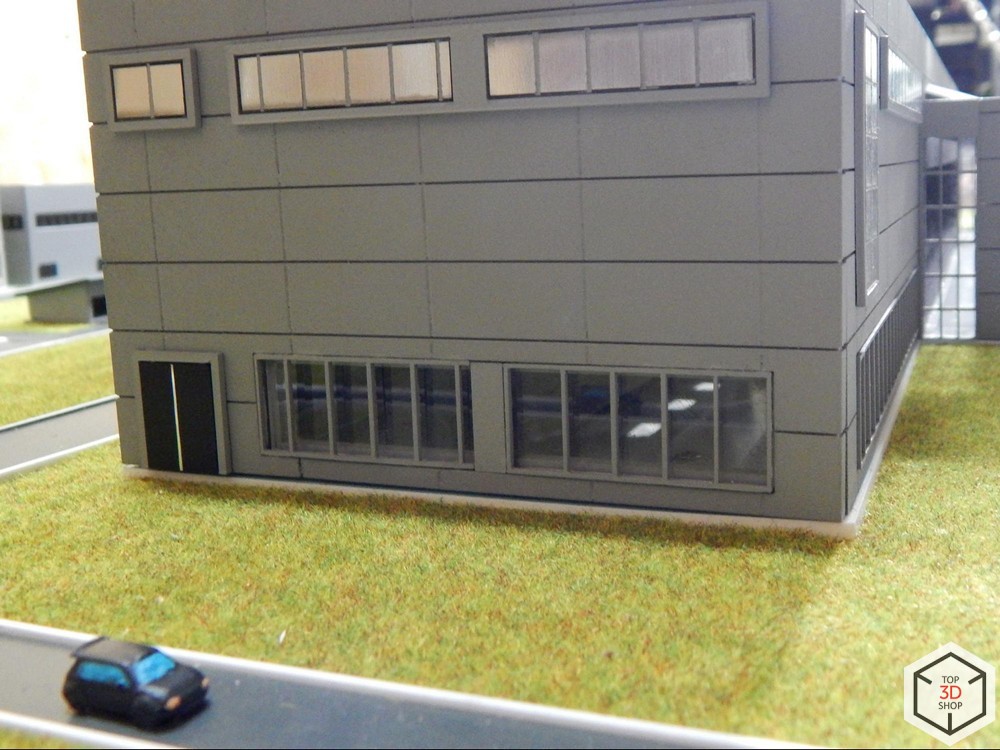

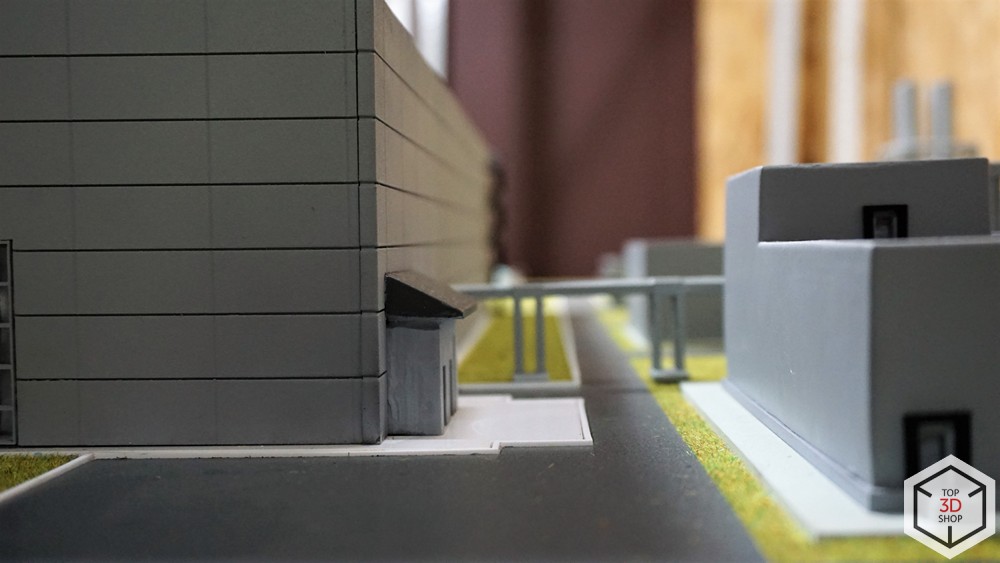

At the stage of evaluation of the layout, it became clear that the main building in the area is quite long. In this regard, it was decided: to make a layout based on the internal "skeleton" of the body. Next - facing, then - small parts. All objects have clear shapes and angles. This observation allowed us to choose the appropriate material - acrylic. It is flexible enough, but not too, just right. When milling or cutting on a laser engraver, the details of the sheet of acrylic remain clear contours and edges.

The frame of the main building consisted of acrylic with a thickness of 4 mm.

This optimum thickness, taking into account the size of the structure itself, is convenient for work and gives sufficient rigidity.

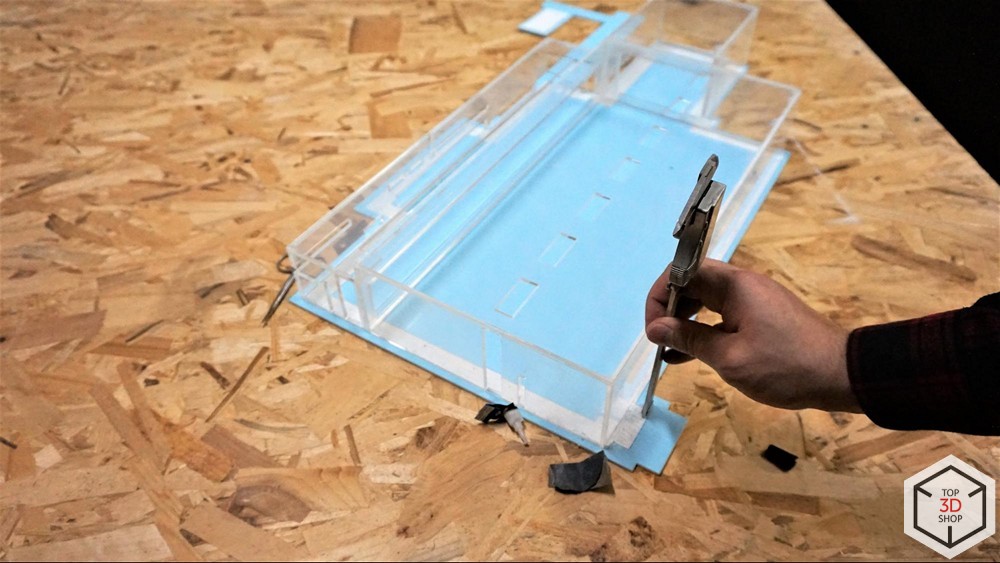

The model was modeled as a combined designer, taking into account the tolerances (0.1 mm) and the thickness of the cut of the laser machine (0.13 mm).

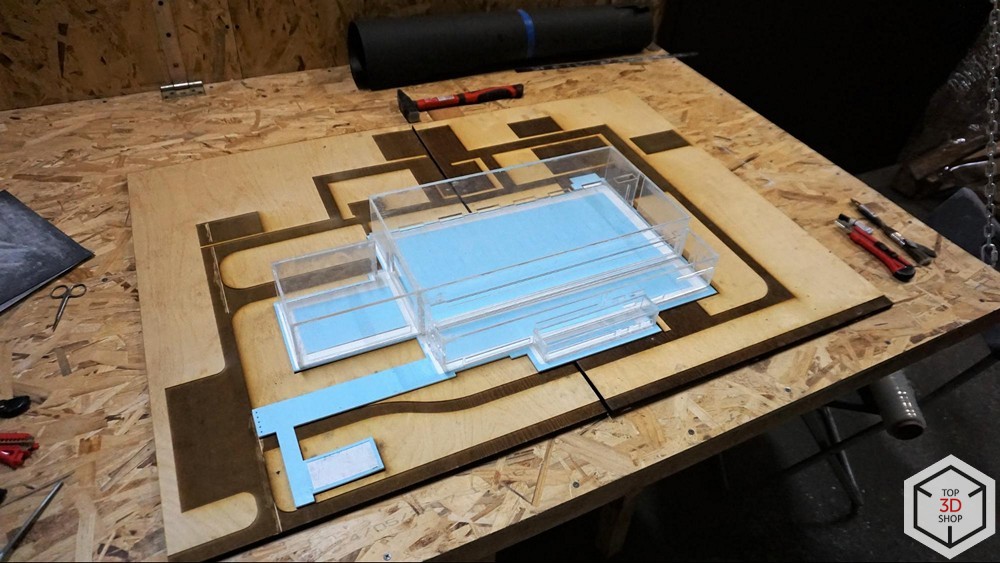

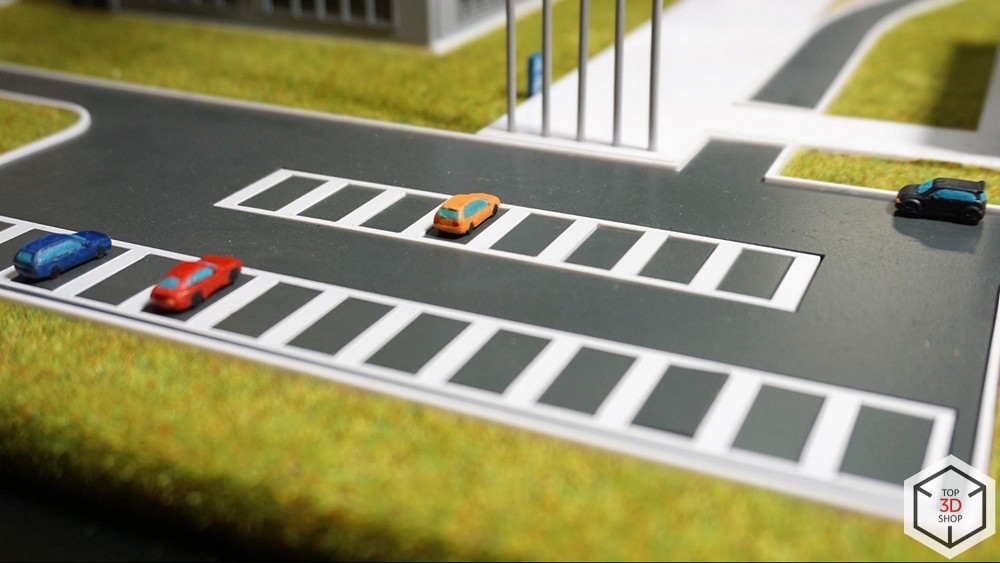

After that, a model of the territory was worked out, paths, building foundations, parking lots, curbs were placed on it. All elements were engraved 1 mm deep, on plywood 9 mm thick, and cut.

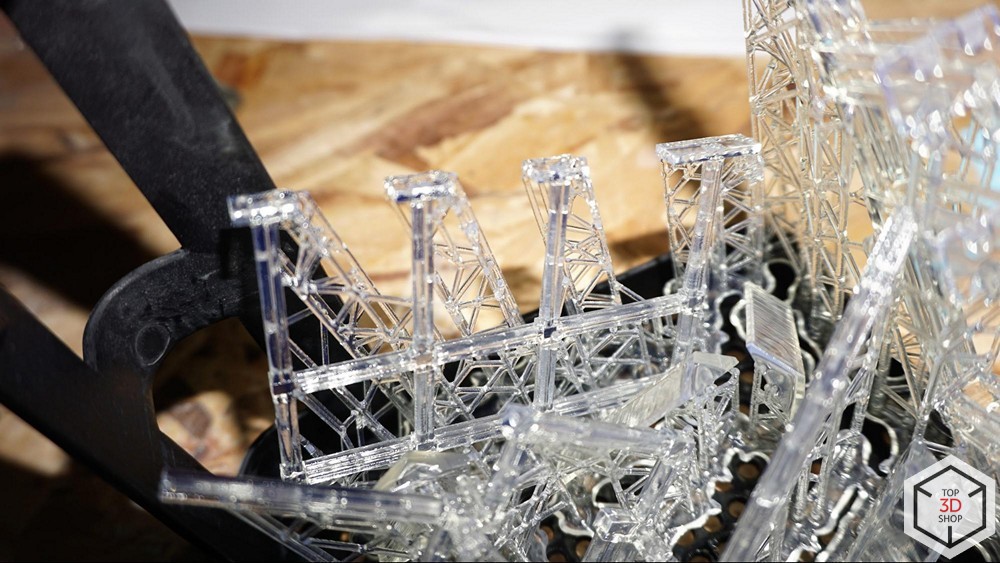

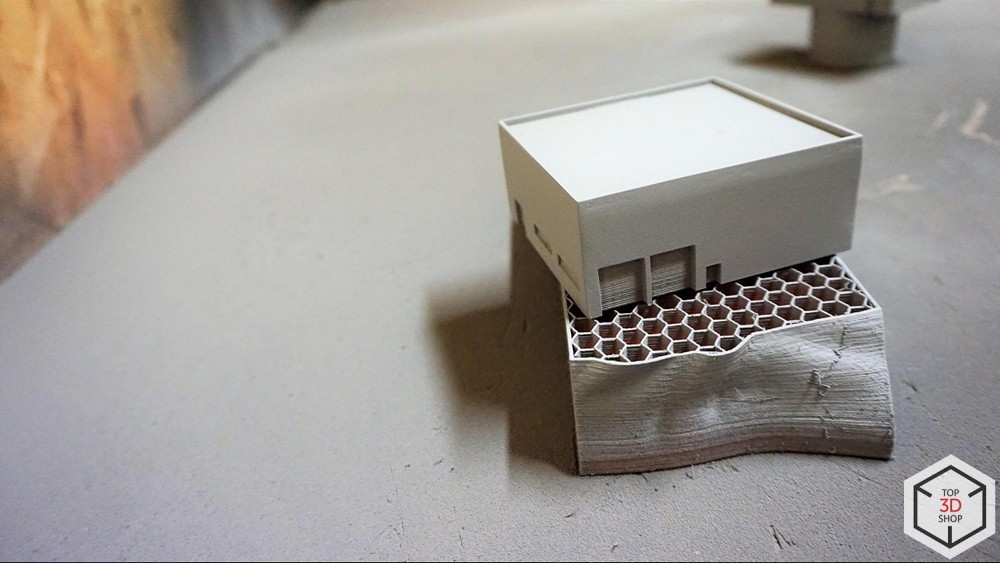

Designed the rest of the corps on site. Half is also produced by the assembly of sheet materials, the second half - by 3D printing using SLA and FDM technologies.

Creature

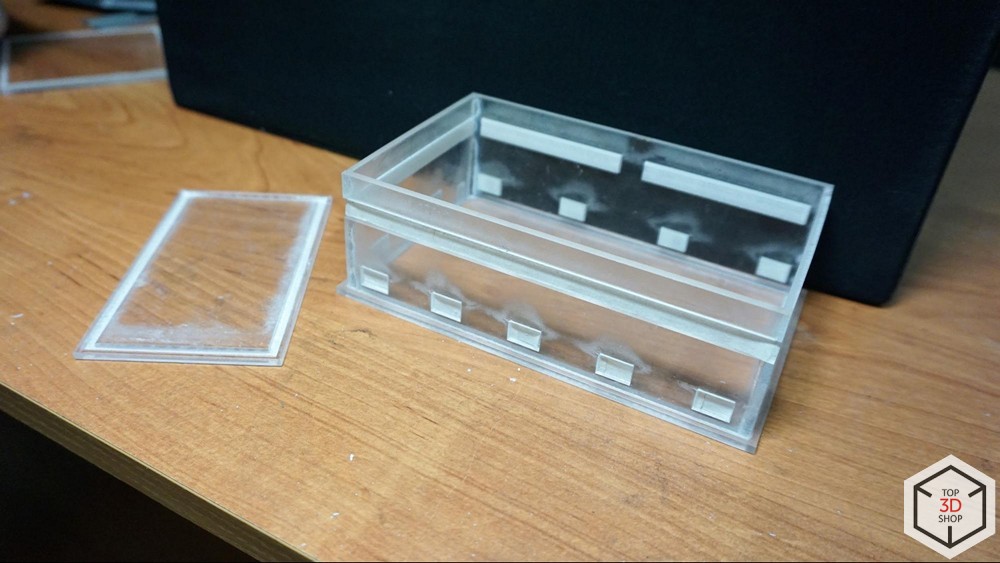

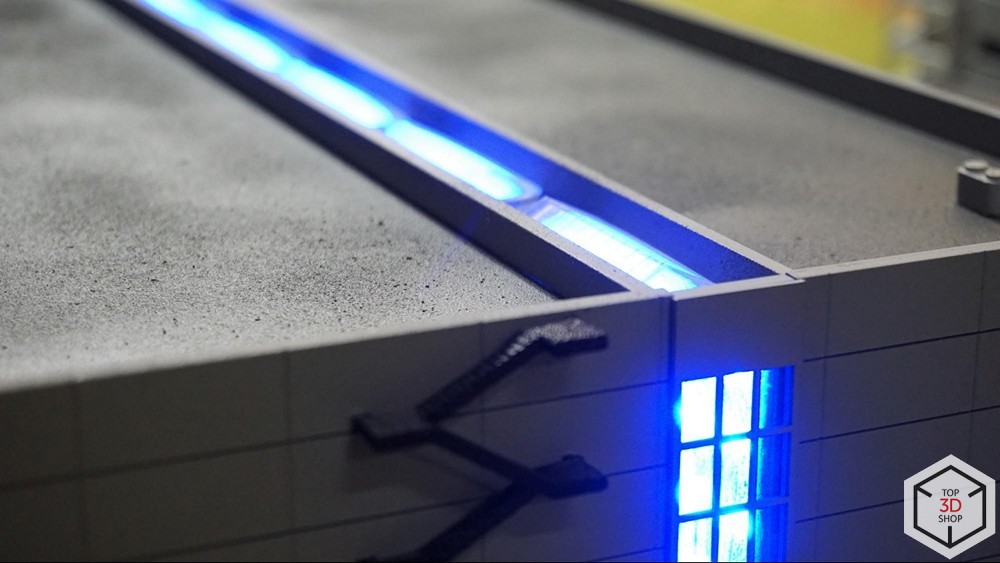

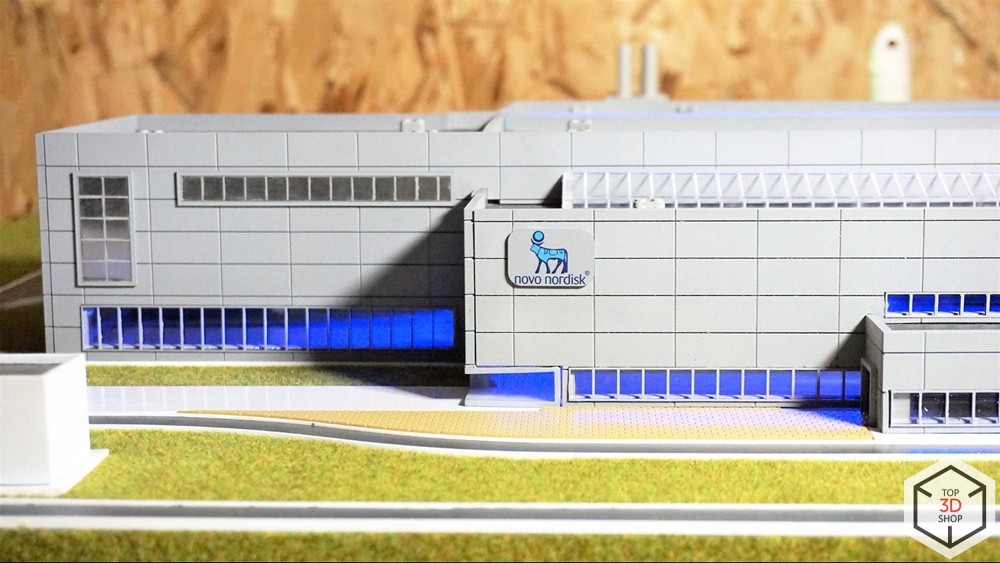

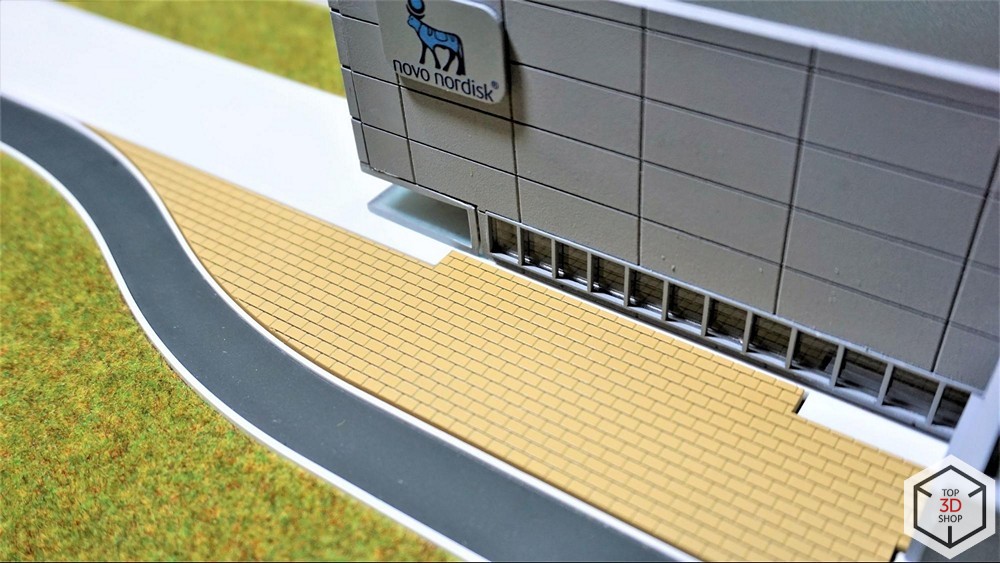

While the builder was processing the finished parts — assembled, ground, polished and polished, the engineers prepared the lining of the main building. The choice fell on acrylic in 3 mm. Engraving relief 0.5 mm. Windows and doors are cut.

Next - assembly-gluing. All elements are agreed as expected. The tolerances indicated above played a role. Layout assembled as a designer.

An OSB plate with a thickness of 15 mm was used for the tray.

Processing putty, then primer, painting in black and a matte varnish in four layers. This is necessary to ensure that the acrylic cap does not leave marks or scratches on the upper surface of the base, to preserve the appearance.

Processing and painting

Further - all the most juicy and interesting. This is the treatment of buildings and painting.

After assembly, all elements were covered with several layers of soil. Thus, we retained the texture and relief on buildings, but at the same time the ground revealed various surface defects.

They were eliminated in the old-fashioned way - by manual machining, sandpaper mostly.

The frame was painted black inside and varnished so that the interior lighting could not be seen through the walls.

It was possible to use black acrylic and not to bother, but transparent was already available and we saved time, which is important - the order time was quite tight.

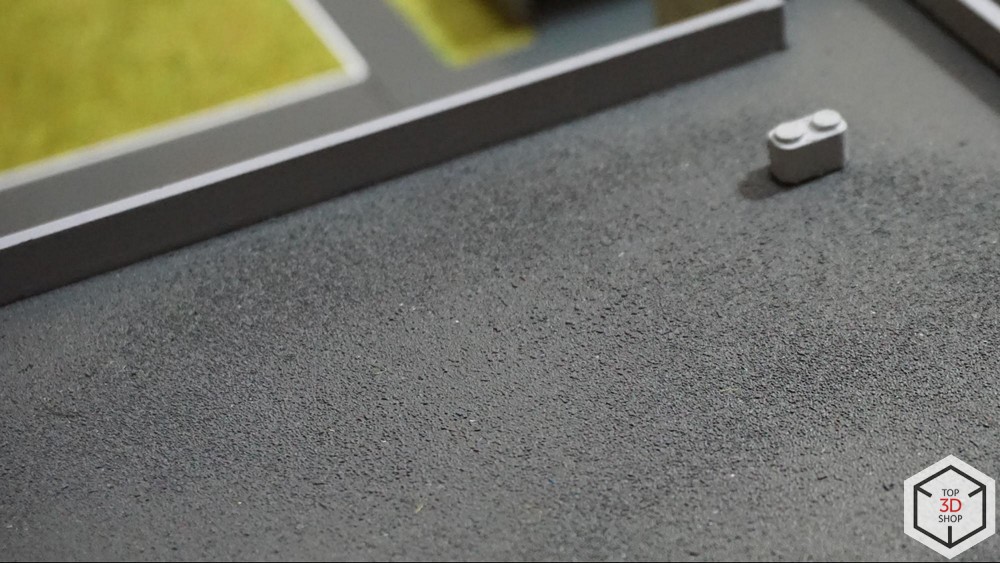

To make the roof textured, we used acrylic polishing dust. Sprayed it when painting. This created a uniform dispersion coating.

Backlight

An important part of the project was the LED backlight. Inside the building was laid the foundation in the form of processed timber. The tape was attached to it. Wires were bred through the base. The power supply is mounted on the bottom of the base. This is a good strategy, as the OSB does not ignite and does not burn. In the event of a fault or short circuit, the backlight will simply fail.

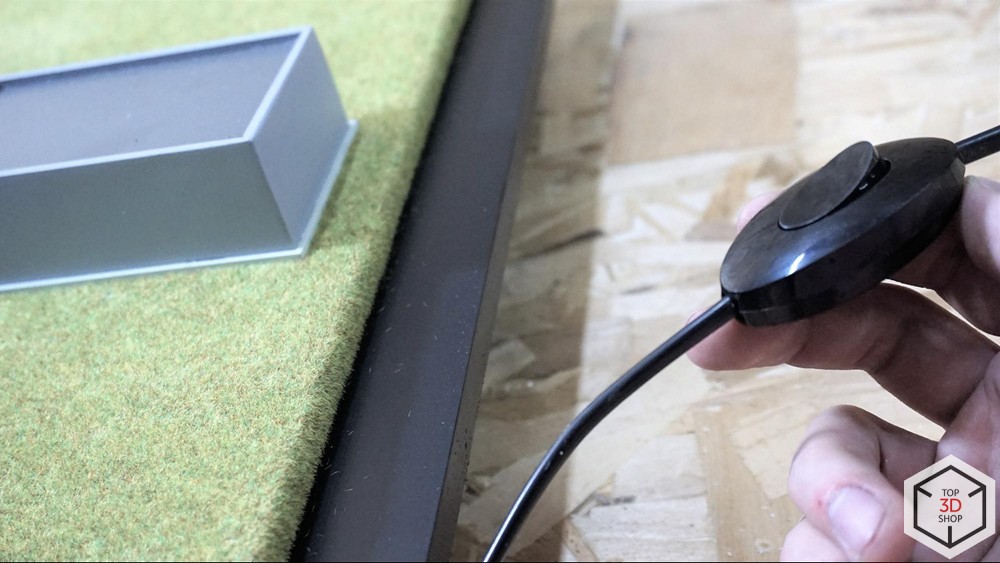

BP removed in a box, printed from ABS plastic on the FDM printer. There is a toggle switch on and off the backlight on the power cord.

Details

The logo was originally designed from a customer’s image. Produced on a Form 2 printer using SLA technology and painted with a brush by hand.

The result did not suit us, the logo was redrawn in high resolution and given to UV printing.

Cars are printed on SLA-technology on the same printer and painted by hand.

One could get somewhere ready, but it would have been longer, and the originality in the project would have decreased.

Pipes are designed and also printed. Processed, polished and painted.

Flagstaffs are made of steel to maintain rigidity with a length of 25 cm and a cross-sectional diameter of 1.5 mm. Laid flock - imitation of grass.

Cap

We made a cap from acrylic 4 mm thick. The cap is one piece and covers the entire layout. Fits with a small gap. Better a little more than not getting into tolerances.

Difficulties encountered and their solution

Already almost finished the layout, we are faced with a problem that is strongly reflected in the entire project. The fact is that the geometry and location of the entrance group on the main building differed on each renderer from the customer, and there was no specific indication of which design was considered the main design, so we had to improvise, which was an erroneous decision - when initially agreeing on the work results, the customer immediately He also pointed out that the entrance group does not correspond to reality, as well as several other minor inaccuracies were revealed.

With the personal participation of the customer, an act was drawn up indicating all the problematic elements, the specified corrections and deadlines for the final version were clearly stated.

findings

At the stage of coordinating large-scale projects, we ask customers many questions and discuss many different subtleties, but this situation once again taught us that there are not many questions and the amount of information received directly influences the result of work.

You can order the exact layout of any object of any required detail by writing to us at msk@top3dshop.ru .

If the volumes are such that you are interested in opening your own workshop, our specialists will always help you choose equipment and materials, write to sales@top3dshop.ru

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/410169/