Snapmaker Compact 3D MFP Review

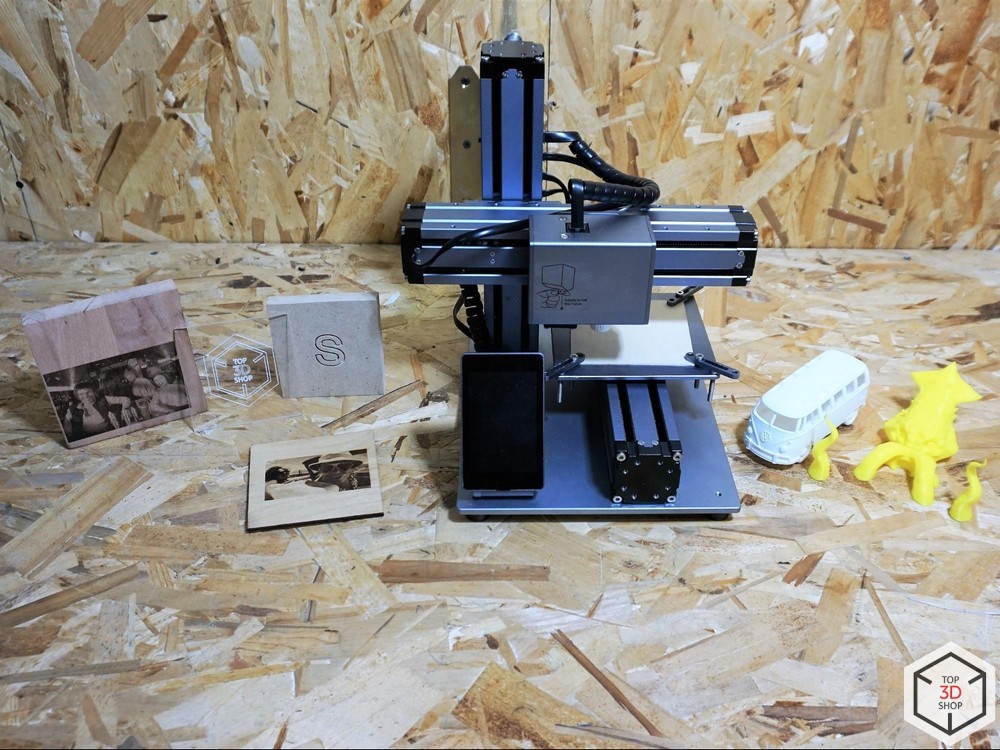

Snapmaker is a compact desktop machine with interchangeable modules capable of 3D printing, milling and laser engraving.

- Manufacturer: Snapmaker

- Model: 3D MFP Snapmaker

- Spindle speed, rpm: 2000-7000 (Nominally - up to 19000)

- Work speed, mm / s, up to: 100

- Actual print speed, mm / s: 40

- Printing area, mm: 125x125x125

- Laser engraving area, mm, up to: 125x125 (actual may differ, more details in the review)

- Milling area: 90x90x50 mm (actual may vary, more details in the review)

- Printing technology: FDM

- Platform heating temperature, ° C, up to: 100

- Nozzle temperature, ° C, up to: 250

- Layer thickness, microns: 50-300

- Laser engraving

- Frezer

- Price, rub: 63,566

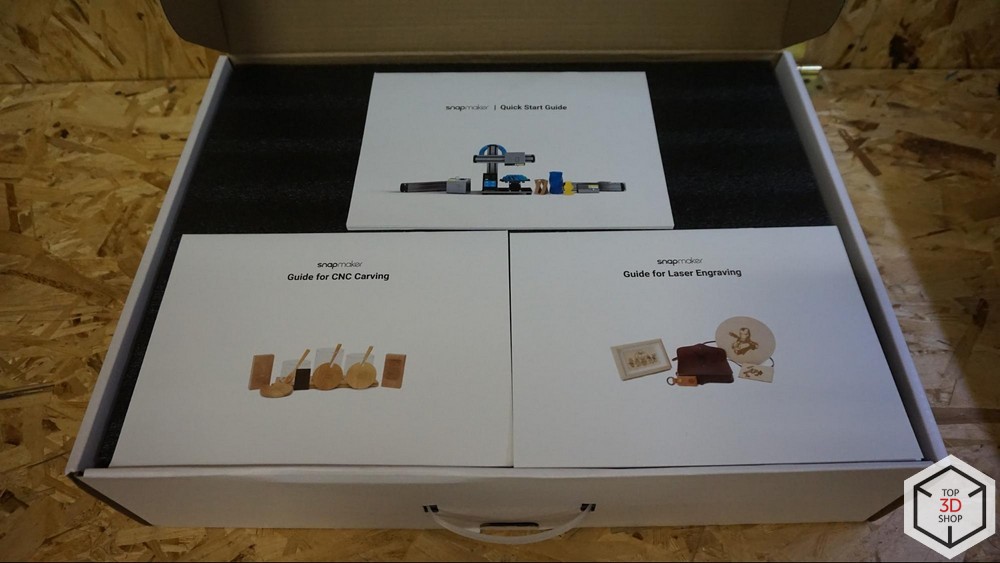

Unpacking

Snapmaker came to us with a review of 2 reels of “native” PLA, yellow and red.

Beautiful box with a description of the contents.

Inside - shipping soft material, something like foam rubber, for preservation.

Inspection brochures, instructions for the machine and its functions.

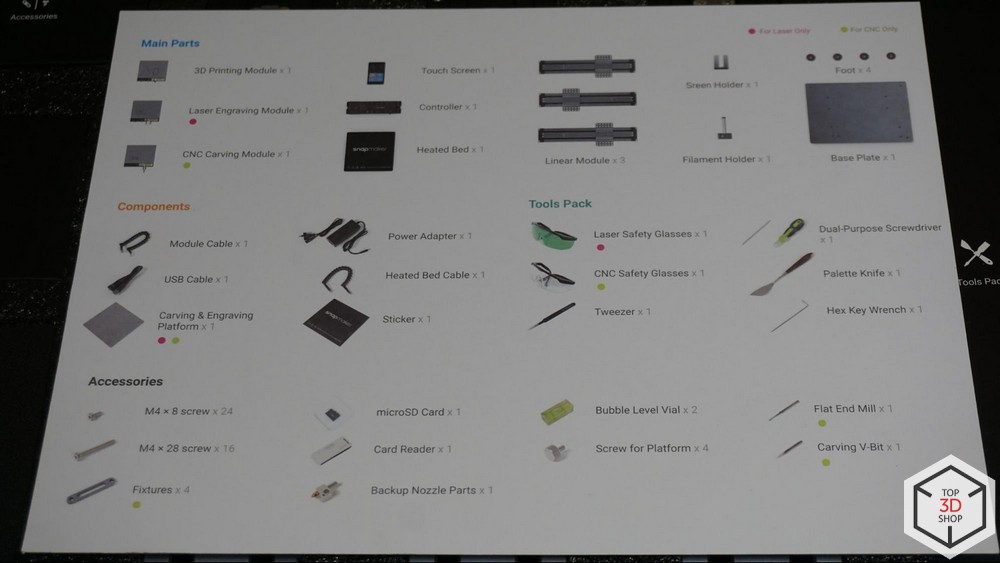

Memory card and adapter to USB port.

Test samples for testing.

The modules themselves that make up the device.

List of contents.

Tools - wrenches and screwdrivers.

All tools are packaged in separate bags.

Two pairs of goggles - transparent for milling, green for the laser.

Connecting cables.

Power adapter.

Touch control panel.

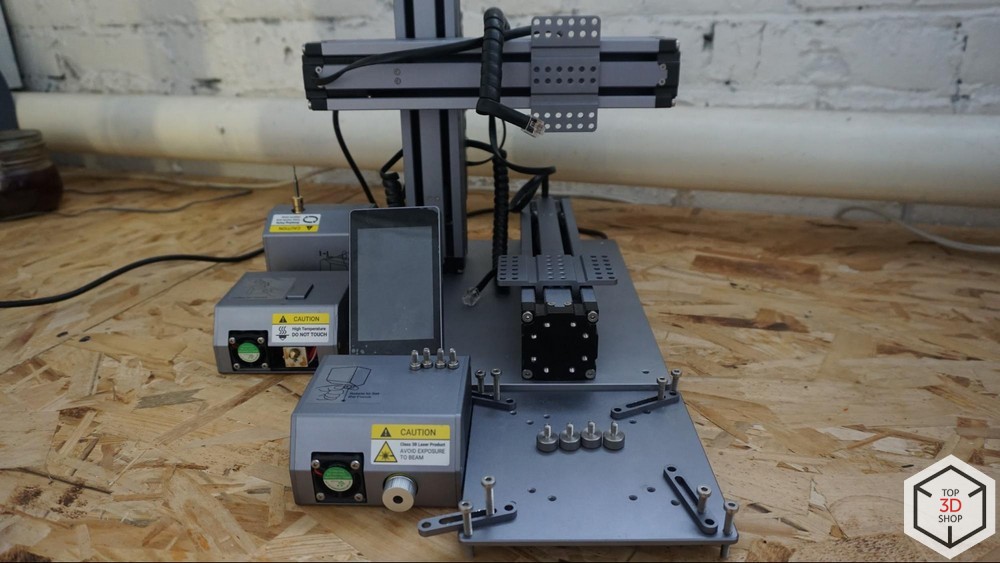

Working modules - laser engraver, mill, 3D-printing unit.

Controller.

Plastic coil holder, removable.

Heated platform 125x125 mm, with interchangeable surface, platform for laser and router and legs.

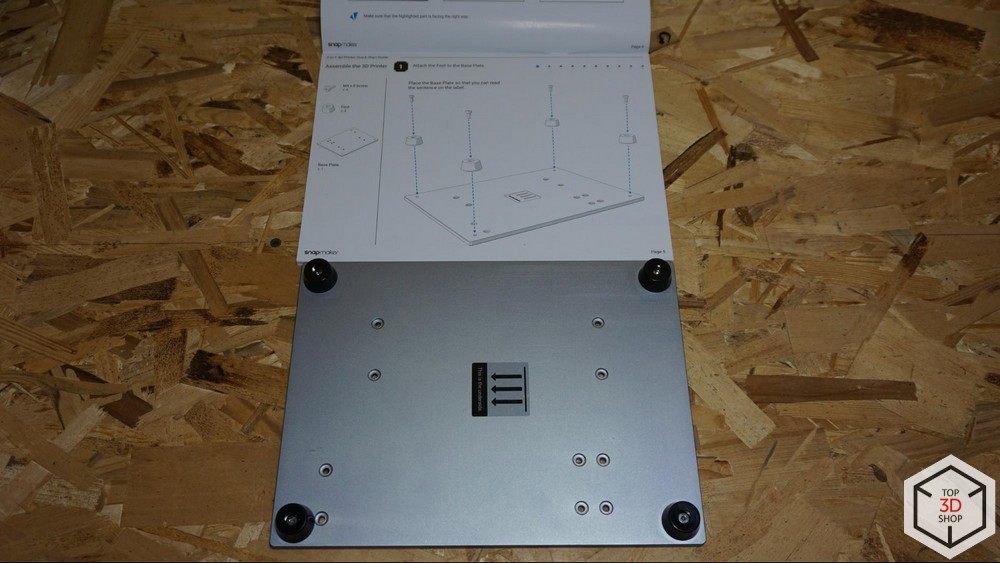

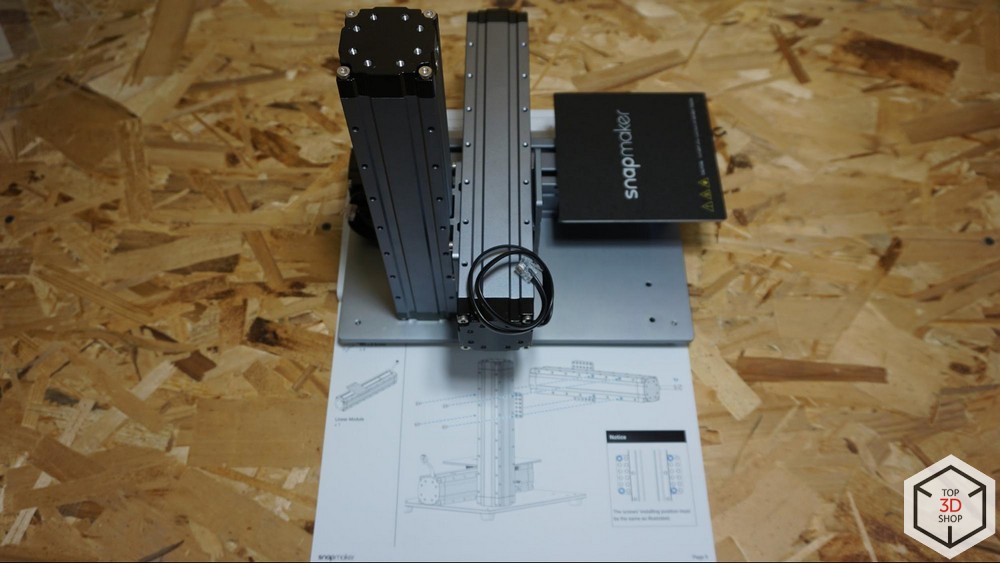

Assembly

Assembly instructions are very visual. It's simple. First, screw the legs.

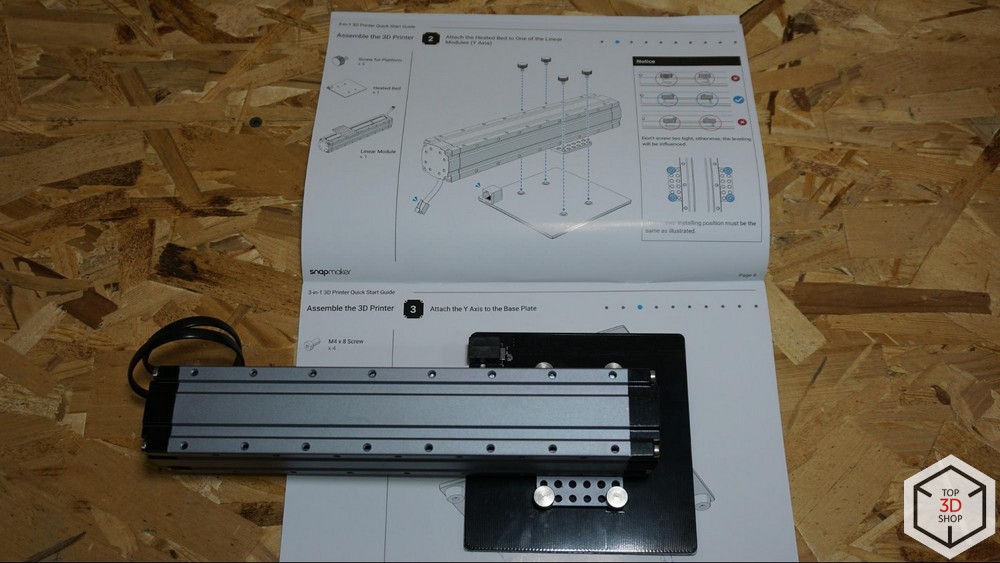

Then we connect one of the shipping modules to the platform.

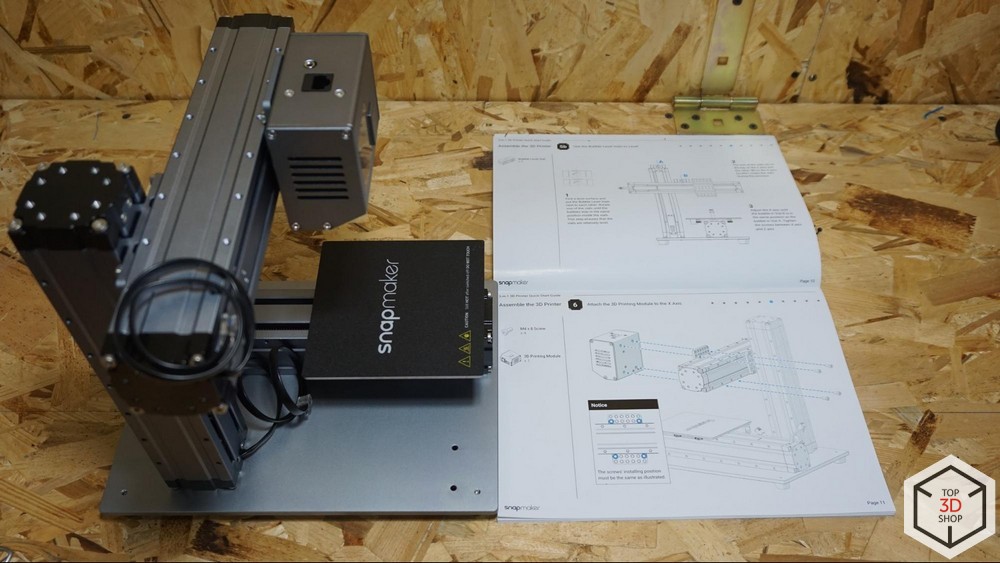

Then two or three more linear modules give the platform total mobility in three dimensions.

We make sure that everything is collected smoothly, using a level.

The worktop of the workbench on which the assembly is made and on which the operation will be carried out must also be strictly horizontal, otherwise incorrect calibration may be possible.

Attach one of the working modules.

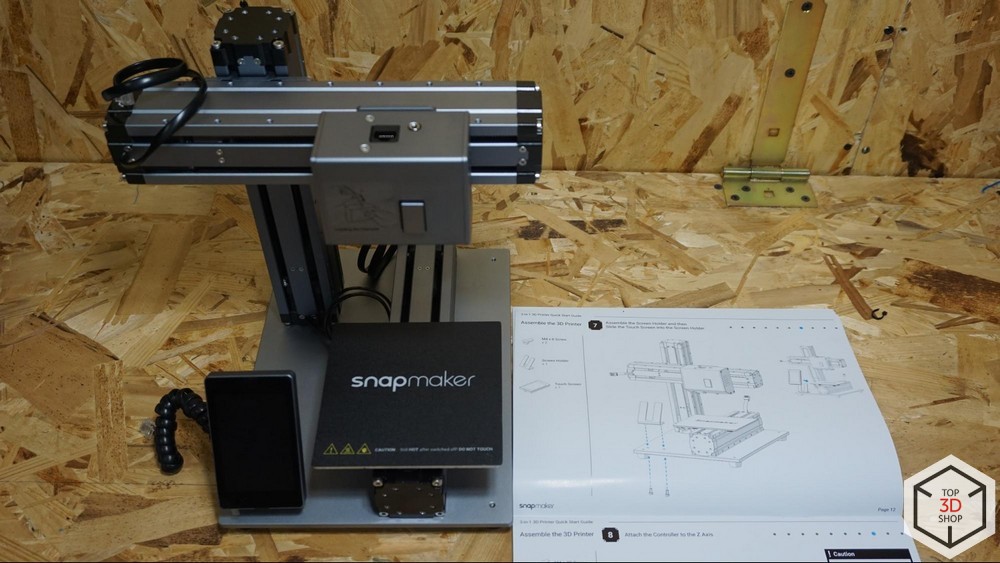

Connect the control panel.

Attach the controller and coil holder.

Connect all the wires and turn on.

The device is ready to print.

Software

The software is divided into three separate parts:

Snapmaker3D for FDM printing.

A simple slicer for working with FDM.

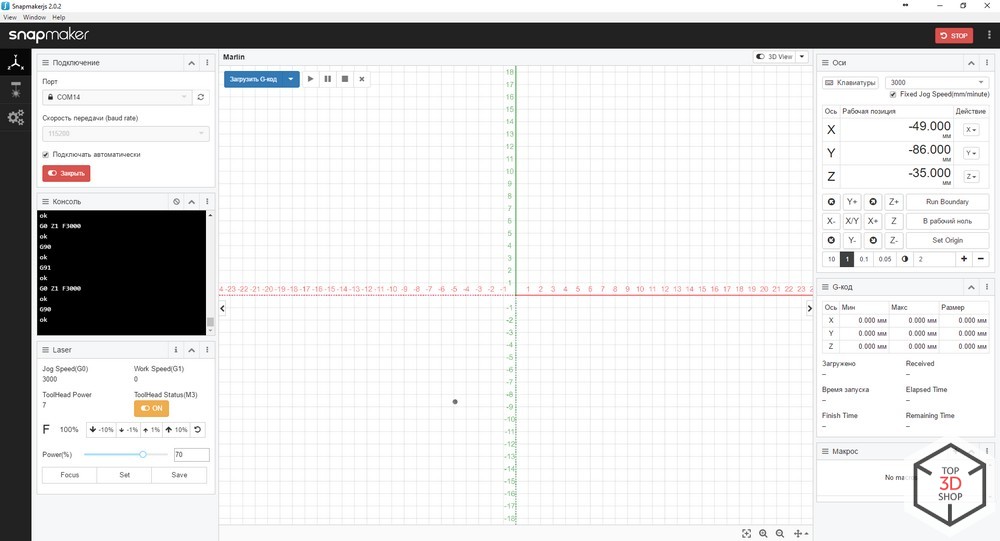

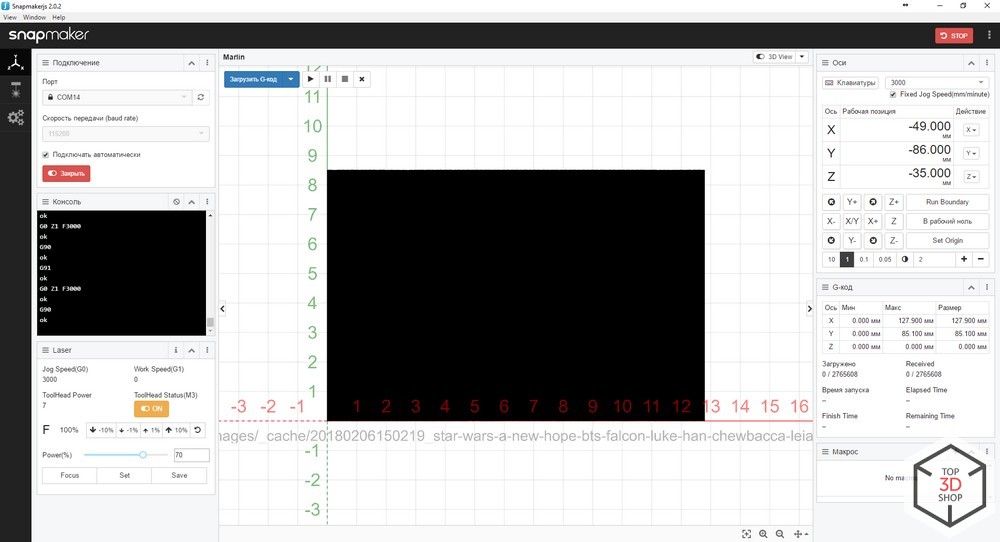

Snapmakerjs - for laser engraving.

Fusion 360 - for milling.

Device operation

Snapmaker is not a professional FDM printer, laser and milling engraver, but is suitable for home and educational use as well as possible. “3in1” is not just a marketing move, this miniature machine will introduce you to three types of equipment and will be very useful in your home workshop.

There are no high speeds here: the print speed according to the preset is up to 40 mm per second, the speed of the laser and the router depends on the model; but this is enough for high-quality execution of 3D-models, accurate laser engraving and application of milling.

Open g-code allows you to use with Snapmaker any programs for the preparation of models that work with this code, such as Simplify3D and Fusion 360.

3D printing

"The attack of Kraken on the Scooby-Doo team", FDM, PLA, Snapmaker

To implement 3D printing, we need to install the head under the FDM and the heating platform.

After installing the head and the platform, we calibrate the table by 4 points in the control panel menu.

By setting the Z-offset at each of the 4 points, we prepared Snapmaker for FDM printing. Next, load the .stl file into the Snapmaker3D slicer and prepare the model for printing.

Snapmaker3D does not stand out among the variety of slicers. This is not Simplify3D, but not Repetier-host, the average functionality of the program.

In this slicer, you can move an object in the XY plane, scale and rotate it.

The settings for the printing process are standard: the choice of profiles, PLA and ABS, four options for presets, the presence of Brim, Raft, Skirt.

In Custom Preset, you can change the values.

Slicer Cons:

1. You can load only one object.

2. You can not adjust the position of the object along the Z axis

Pros:

1. Simple and intuitive interface

2. Output file format - .gcode

3. Ability to work with Simplify3D

Video Print:

Laser

To prepare Snapmaker for laser engraving, we need to remove the heating table and the FDM head, set the table with the mount for materials and the head with a solid-state laser.

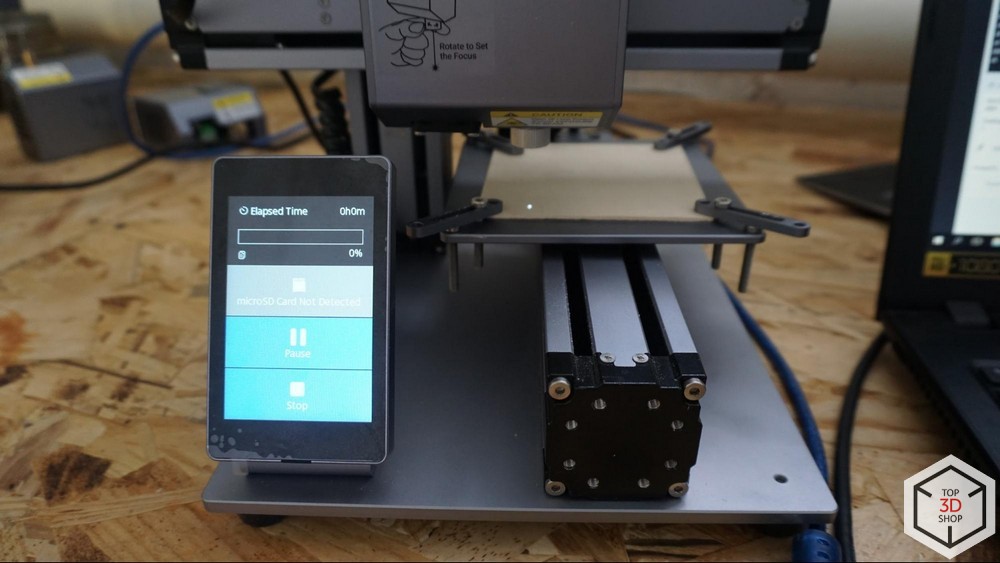

After that, we connect the Snapmaker to the PC, connect via the com port and focus the laser.

The engraving area is quite small - it is 80x80 mm. Nominally, it is 125x125, but when using standard clips decreases along the edges. If you are ready to risk and engrave without fixing the workpiece, you can use the entire area of the platform.

Focusing is done manually. It is necessary to achieve the smallest point.

You can control the position of the head and height in Snapmakerjs, the module itself also has focus controls.

This program has three functional windows:

1. Workspace window

2. Picture preparation window

3. Window with program settings.

In the workspace window we can control the position of the laser and the focusing power, we can see the display of the commands being executed, set the speed of the passage, set the relative zero.

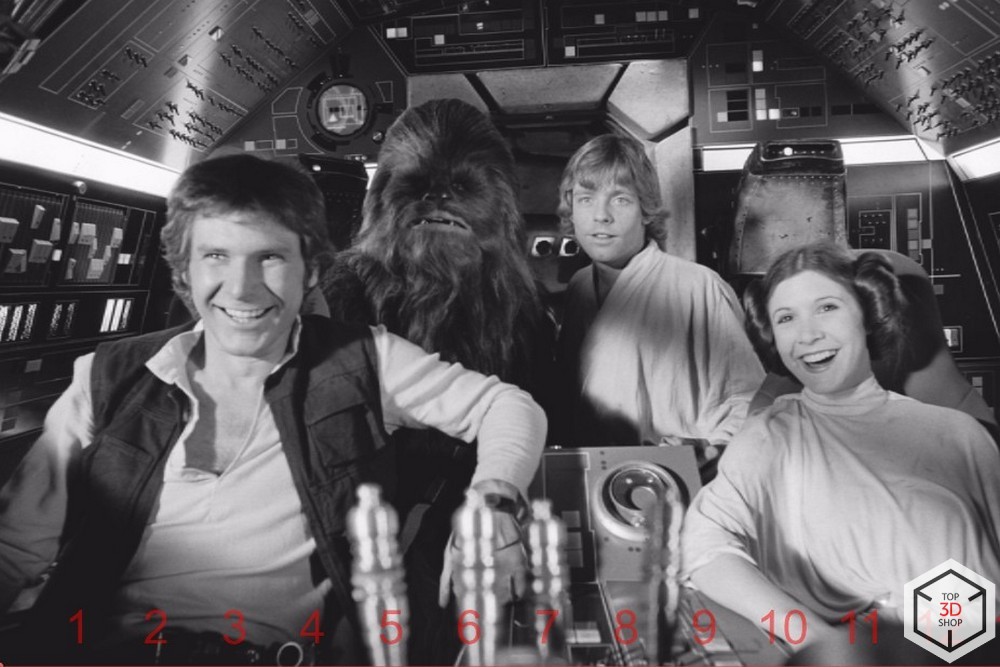

In the window with the preparation of the picture, adjust the dimensions of the picture, contrast, brightness, image processing method, display quality. Here is formed gcode for laser engraving.

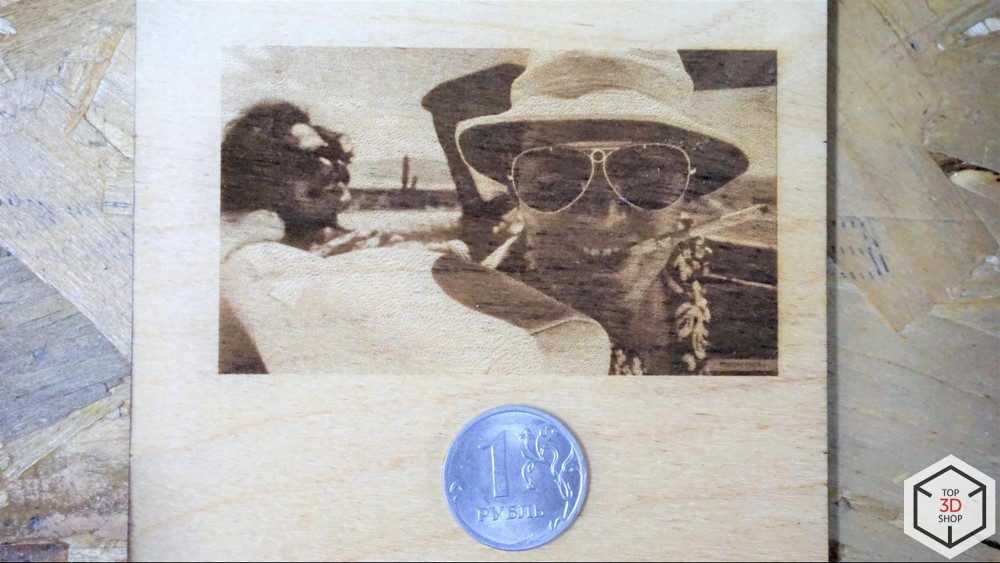

In this case, we are processing the image in grayscale mode. The image is raster, from separate points, but not curves.

After setting the settings, you can see the preview and form the final gcode. Processing a vector image here is similar to the work of CorelDraw.

Here we see a black rectangle. Upon closer examination, it becomes clear that this is the visualization of the path that the laser will follow and burn the image, point by point. The process is quite long, can not be said about the engraving of vector drawings.

Logos are much faster burned in the mode of black and white engraving, through the vector. But in a raster format, a much more interesting result is obtained.

Milling

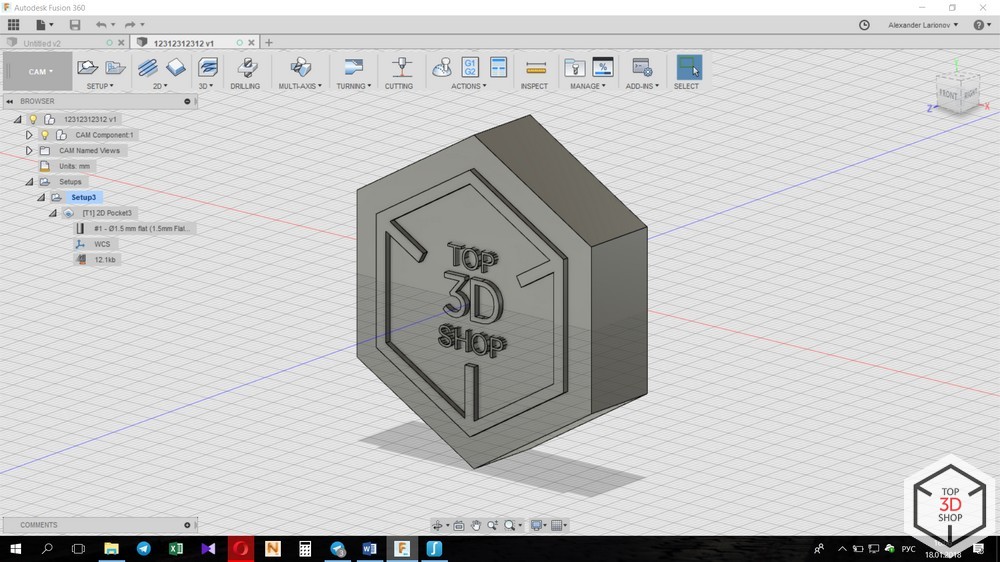

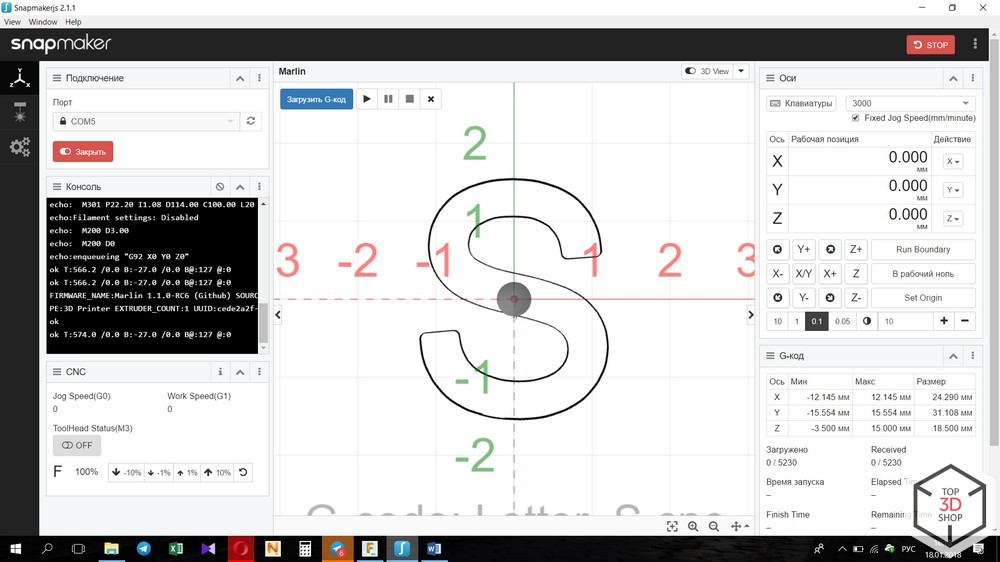

To prepare for milling, to create 3D models and generate control programs of the standard gcode format, you will need the free Fusion 360 program, then the Snapmakerjs program to broadcast gcode to the machine itself.

For the first milling, no special knowledge is required, except for a minimum knowledge of English - the whole process is described in detail, step by step, in the instructions .

To begin with, we are offered a simple example - cut out the Latin letter S. To do this, we need to open the Fusion 360, create the outline of the letter and “extrude” it.

Then, using the CAM tab, we create the path of the cutter.

After that, gcode is saved and transferred to Snapmakerjs.

We start milling and watch the process.

Then you can experiment and make something more complicated.

The nuance about the milling area - nominally it is 90x90 mm and 50 mm in depth, but when using clamps the area is reduced to 80x80. Ie, in fact it turns out 80x80x50 mm.

Advantages and disadvantages

Pros:

- compactness

- mobility,

- easy handling,

- quality,

- appearance.

Minuses:

- small work area

- low spindle power

- large reach cutters

- insufficient rigidity for serious milling.

Because of all this, milling is extremely slow. This machine is still designed for engraving, and not for serious milling.

In order to discourage the working zero, in any case, you will have to connect the device to the computer. Then you can run the control program from a flash drive.

There is no feed adjustment in the process; you can only adjust it before running the control program and only from a computer.

Good for engraving small printed circuit boards for home-made electronics.

Impression, comparison

Compare with SkyOne .

What is the difference:

1. Scara movement mechanics in SkyOne, against the Cartesian system on Snapmaker. The unevenness of the movement of the mechanics of Scara will affect the resolution during laser and milling engraving. The Cartesian system has no such problems.

3. Both printers do not have sufficient rigidity for 2.5D milling.

4. The construction area for Snapmaker is 125x125x125 mm, and for SkyOne — 140x190x200 mm.

5. On the other hand, Snapmaker has a layer thickness of 50 microns, which is exactly two times thinner, which will give a smoother surface to an FDM print.

5. More convenient software from Snapmaker.

Answers to questions on past reviews

- I wonder what the moving parts?

If we partially disassemble one of the linear modules, we find a fairly simple system on four rollers of light plastic. We did not do chemical analysis, but most likely it is nylon or fluoroplastic.

The solution is quite budget and simple. However, it should be noted the high quality and accuracy of the execution of the milled elements of the housing, as well as the assembly inside the modules. The rollers do not hang out and provide sufficient rigidity to work all three types of nozzles.

- I did not notice any table calibration options. Sensor Z, I also do not see. They hope that such brutal beams will allow them to set zero once at the factory and that's all? Well, good luck, they will need it.

Calibration is carried out on four points of the platform. In the program you need to adjust the clamp on each of the 4 points in sequence. Thus, by introducing software correction of the distance between the nozzle and the platform, Snapmaker completely eliminated the need for adjusting screws.

- How is the rigidity of the structure ensured?

For an FDM and a laser, with such small processing areas and print volumes, stiffness plays a small role. Milling on Snapmaker is relevant for educational and entertainment purposes, it is unlikely that anyone would think to create a prototype of a serious industrial device on it.

Power is small, the rigidity is appropriate.

- What is responsible for the accuracy of positioning?

There is no ballscrew. Standard screw drive with tension spring. It is unlikely that someone confuses in our time.

Results, conclusions

Snapmaker is not an industrial machine. This is not the 3D printer, mill or laser cutter that will produce tons of 24/7 products.

If you need a machine or printer for commercial use, this is definitely not your choice.

This is a miniature desktop machine for learning, entertainment and creating unique do-it-yourself gifts. With it, you will teach your child the initial skills of working with modern technology, and with three types of machines at the same time. And you can please with such an original and useful gift and adult. Few people will leave him indifferent.

Although Snapmaker does not have precise accuracy, rigidity, volumes of the working area - it has a different purpose, and it performs it. With his goals, he copes perfectly. And besides, it looks very good.

Buy Snapmaker and get free training you can in the Top 3D Shop. When you purchase it, you will also receive a discount on consumables - up to 20% for the whole 2018.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/410313/