Toyota develops heat-resistant magnets with reduced neodymium content

Neodymium magnets are used for various engines, such as high-power engines, in electric vehicles that are expected to develop intensively in the future. Toyota is going to reduce the amount of neodymium (Nd, rare earth element) by developing a new heat-resistant magnet with a low neodymium content. (Toyota press release from February 20). Toyota is supposedly trying to circumvent the dependence on Chinese rare earth elements for its electric vehicles.

This study was conducted in the framework of the NEDO project "Development of magnetic materials technology for high-performance engines of new generation cars."

Background question

In hybrid cars and electric cars, it is important to develop not only batteries, but also high-performance motors. The higher the magnetic flux density of the magnet, the higher the engine performance. And since the alloy of neodymium with iron and boron (Nd 2 Fe 14 B) provides the highest magnetic flux density, it is currently the main ferromagnet in electric motors of electric vehicles.

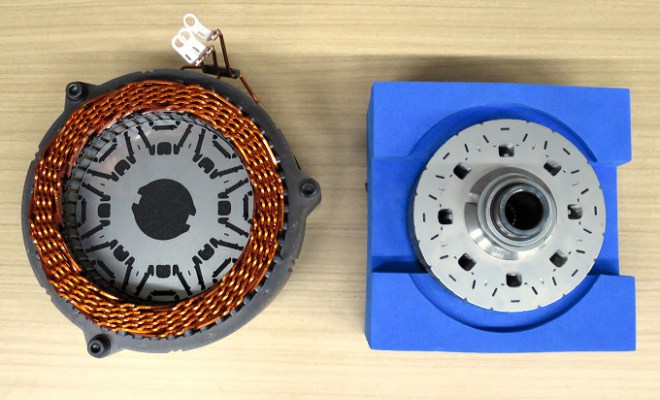

Electric motor model with a niodium magnet (left).

On the other hand, neodymium magnets have a serious disadvantage that the magnetic field weakens as the temperature rises * . If you add to the neodymium terbium (Tb) or dysprosium (Dy), you can suppress the decrease in magnetic flux.

Neodymium magnet ( right ) loses its magnetic properties with increasing temperature.

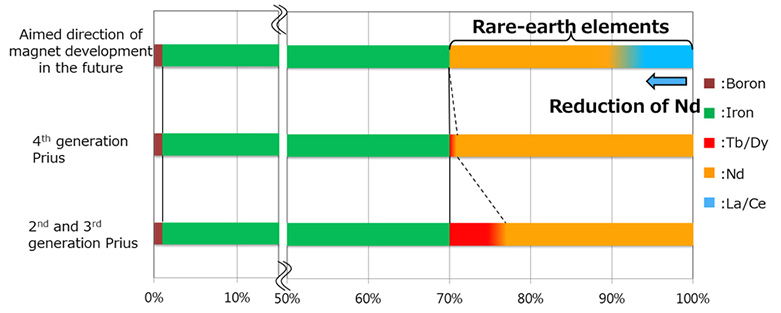

Despite the fact that a neodymium magnet with the addition of terbium and dysprosium is not subject to disadvantage, the difficulty lies in the fact that dysprosium and terbium are rare earth elements and relatively expensive (price 1 kg ~ $ 561, dysprosium 1 kg ~ $ 234 for December 2017) . Neodymium itself is inexpensive (1 kg ~ $ 47), but there is a fear that it will not be enough as demand increases. Moreover, the problem also lies in the fact that a high proportion of imports from China of niobium and other rare-earth elements in general. In this regard, it is necessary to develop high-performance magnets, which uses as little as possible elements of terbium-dysprosium-neodymium.

The direction of the development of magnets. With the 4th generation of the Prius and the Prius of the second and third generations (from the press release of Toyota)

Stages of technology development

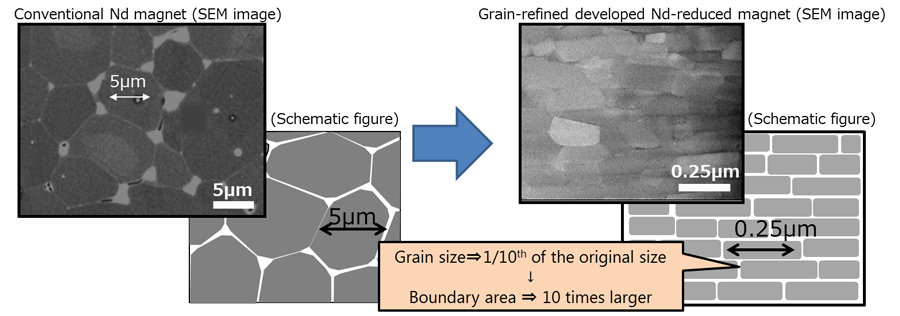

Stage 1. Reducing the size of the grains that make up the magnets

It was possible to increase the area of the boundary zone between the grains ( grains ~ individual crystals of the magnetic material), reducing the grain size and thus suppressing the decrease in the magnetic flux even at high temperatures.

Grain Difference

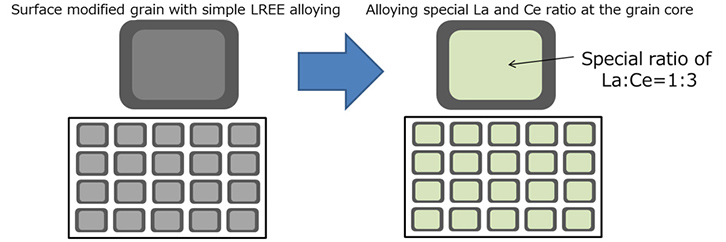

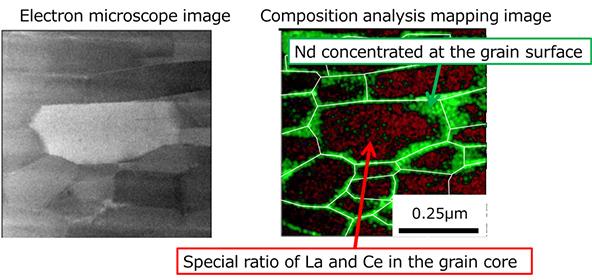

Stage 2. Getting a two-layer structure with high grain

In a conventional neodymium magnet, neodymium is evenly distributed inside the grains of a ferromagnet. Moreover, it turned out that the total amount of neodymium is greater than that necessary to maintain coercivity ( resistance to demagnetization ). The increase in the content of neodymium on the surface of the grain leads to an increase in coercivity, which also reduces the total amount of neodymium used in the new magnet, without loss of efficiency.

Stage 3. The specific ratio of the components of lanthanum and cerium

It was possible to reduce the concentration of neodymium with the addition of lanthanum and cerium, while maintaining the same efficiency as conventional magnets. Lanthanum and cerium cost less than $ 10 per 1 kg, which is quite inexpensive for rare-earth elements. However, with the current price difference, if the neodymium content decreases by 10%, this will not lead to a significant gain. Therefore, most likely, a new technology will be needed when the demand for neodymium expands and the price rises.

Schematic representation of polycrystal grains (from Toyota press release)

SEM polycrystal grain (from Toyota press release)

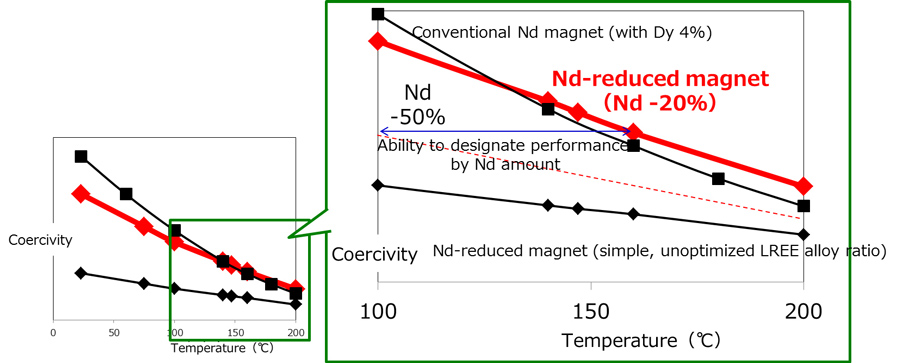

Performance comparison Even with a 20% reduction in the neodymium content, the same efficiency is achieved as with conventional magnets at high temperatures (from the Toyota press release).

Notes:

Please write about errors.

- the translation is not literal

- added missing parts from press release

- Up. changed the title based on the comment . It became seoshno, but a little more accurate.

Please write about errors.

Source: https://habr.com/ru/post/410387/