Lithium niobate - the possible future of optoelectronics?

Our world is full of a wide variety of materials, substances, chemical compounds, etc. Each of which has its own properties, its own advantages and disadvantages. Many scientists spend years trying to rid one or another material or chemical compound from deficiencies, thereby enhancing its quality, which, in turn, expands the range of possible applications. This is what researchers at Harvard University are doing. Their "experimental" was a very unusual compound - lithium niobate. What exactly did the scientists do and what results did they get? Let's find out. Go.

"Experimental": what, how and why?

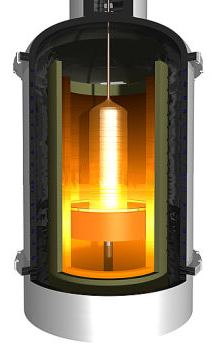

The basis of research has become lithium niobate. This is a crystalline chemical compound that is chemically inert and has very surprising optical properties. Lithium niobate is formed by combining niobium oxide and lithium carbonate at a temperature of about 1100 ° C. It uses the Czochralski method.

Schematic representation of crystal growth by the Czochralski method

What is special about this compound? As mentioned earlier, these are its optical properties. The fact is that lithium niobate crystals are optically transparent in the wavelength range of 0.4-5.0 μm, and the refractive index of the ordinary beam is 2.29, the extraordinary - 2.20. Due to such characteristics, this chemical compound has found its application in many devices, ranging from mobile phones to optical modulators.

Lithium niobate structure

Unlike silicon and problems associated with it

When we talk about electronics, the first chemical element that comes to mind is silicon. It is widely used in electronics, including optoelectronics. Its main difference from lithium niobate is the ease of chemical etching. This treatment process is used to create nanometer-sized structures, such as waveguides. Lithium niobate, in turn, is not amenable to such processing.

Schematic representation of the chemical etching process.

There have been attempts to create waveguides based on lithium niobate using ion diffusion and proton exchange. However, as a result, the optical index contrast between the waveguide and the body material was too low. But it should be different, because the higher this indicator, the better the light will propagate through the waveguides etched in lithium niobate, which will make full use of the optical properties of the material.

Some researchers believe that this problem can be solved by hybridization. Waveguides etched on the surface of silicon direct light through lithium niobate, where it exploits the transparency of the material and its non-linear optical properties. This method is quite efficient, but inefficient, because the connection between the light passing through silicon waveguides and lithium niobate turned out to be too weak.

New method straight from Harvard

The difficulty of working with materials such as lithium niobate, prompted researchers from Harvard University to discover a new etching method. Namely, plasma reactive ion etching.

During this process, the surface of the crystal (in this case, lithium niobate) is bombarded by ions. In this case, the areas exposed by the photomask are removed by the interaction of ions with atoms on the surface of the chip.

Marco Loncar, head of research, speaks, not without humor, about lithium niobate as follows:

Over the years we have been dealing with many materials that have good properties, but it is difficult to work with them. One of these materials is diamond. Diamond is actually easier to etch than lithium niobate, but it does not exist as thin films (thin layers of material, from fractions of a nanometer to several microns).

Words are words, but any study requires physical evidence. As these, a micro-ring and several bands were created, the width of which was about 1 μm, and the radius of the ring - 80 μm.

The process of creating this microcreation can be described in 3 steps:

I step - waveguide samples were etched on a photoresist layer using electron-beam lithography;

Step II - the resulting template was applied to a lithium niobate film in order to protect the necessary areas from further processing;

Step III - using a plasma jet ion etching beam of argon ions was directed to the sample. As a result, the areas not protected by the photomask were removed, and the necessary waveguides were formed.

What is even more pleased with the researchers is that the loss of optical power at a distance of 1 meter was about 50%. While previously, when using lithium niobate, this figure was 99%. According to Lonchar, this became possible due to an increase in optical confinement, which prevents the light from "leaking" along the edges of the waveguide.

Marco Bazzan, a materials scientist at the University of Padua, said:

If the research results are confirmed, it will increase the significance of lithium niobate, even if traditional silicon photons are taken into account. Such good performance in combination with the nonlinear optical properties of lithium niobate attaches great importance to this work, especially in the coming era of integrated quantum photonics.

It is the integration of lithium niobate into silicon photonics that is the vision of the future team of Loncar researchers. However, at this time for this they will again return to the hybrid model, due to the fact that there is simply no production of devices based on lithium niobate. Therefore, according to Lonchar, they have to make chips of lithium and silicon niobate separately, and then combine them into a single whole.

To familiarize yourself with the report of the Loncar study group, you can follow the link .

Epilogue

The use of lithium niobate in optoelectronics has many difficulties, however, many advantages that are worth the effort. Perhaps the time will come when the good old silicon fades into the background and becomes a relic of the past, but so far it is not. At the moment, a lot of research is being conducted, the purpose of which is the discovery of new chemical compounds and materials or a more thorough study of existing ones, with the aim of using them in various spheres of our life. There is no limit to perfection. This principle applies to the smallest, but sometimes the most important, details of any technology.

Thank you for staying with us. Do you like our articles? Want to see more interesting materials? Support us by placing an order or recommending to friends, 30% discount for Habr users on a unique analogue of the entry-level servers that we invented for you: The whole truth about VPS (KVM) E5-2650 v4 (6 Cores) 10GB DDR4 240GB SSD 1Gbps from $ 20 or how to share the server? (Options are available with RAID1 and RAID10, up to 24 cores and up to 40GB DDR4 RAM).

Dell R730xd 2 times cheaper? Only we have 2 x Intel Dodeca-Core Xeon E5-2650v4 128GB DDR4 6x480GB SSD 1Gbps 100 TV from $ 249 in the Netherlands and the USA! Read about How to build an infrastructure building. class c using servers Dell R730xd E5-2650 v4 worth 9000 euros for a penny?

Source: https://habr.com/ru/post/410499/