Flippy's mechanical arm has learned to perfectly turn the chops

Frying meat is an intellectual job that requires experience and skills. You need to constantly monitor the smell, the degree of roasting, color on both sides, temperature and other factors. Complicated analysis is performed to make an important decision when to turn the meat to the other side. They say that men are better adapted to such work. If so, then now the strong sex has a worthy competitor - the Flippy robot. The first robot in the world who can turn burger cutlets, began work in CaliBurger Californian eatery. The robot is manufactured and trained by Miso Robotics, which specializes in robotics and Artificial Intelligence systems.

Strong mechanical arm, thermal imaging, accurate sensors, machine vision in 3D, the ability to work around the clock - here the iron chef has an advantage over man.

"The key to success in the restaurant industry is consistency," said John Miller, executive director of Cali Group, which owns a chain of restaurants. “Therefore, every time you go to CaliBurger anywhere, you know that the cutlet [in the burger] will be cooked exactly the same.”

True, the robot Flippy has not yet mastered absolutely all the necessary movements, so it cannot completely replace a person and, for example, open his own fully automated snackbar. To just put the meatballs out of minced meat on the grill, you need an assistant. Then the person will appear a few more times: to put the cheese on the cutlet and add other ingredients, such as salad and sauce. This is the finishing stage, when the burger is almost ready. It is possible that in the future they will be able to automate.

Flippy is a relatively small robot on wheels with a mechanical arm that moves in 6 degrees of freedom and a “touch panel” (cameras, 3D, thermal sensors). He gets a burger cooking team directly from the diner’s computer network as soon as the customer breaks through the order at the checkout counter.

The leaders of the company Miso Robotics do not think that robots will completely push people out of the kitchen. Most likely, in the future they will work together, helping each other. But it is clear that the work of the cook at the same time change. As in many other professions, cooks will also have to become a little programmers - to lay the necessary frying program, change the settings of the robot, etc.

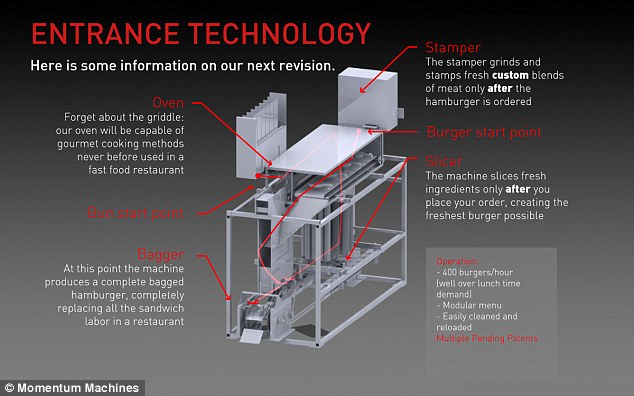

Flippy constantly monitors the temperature of the cutlets, the surface temperature of the grill (thermal photography) and the size of the cutlets themselves. All of this comes as input to the neural network, which makes the decision to turn the patty. What is most interesting, the robot is set to continue training in the course of work, so the more cutlets he does - the more he gains experience and improves his skills. In this difference, Flippy is different from other robot cooks that are being developed in other companies. For example, Momentum Machines first announced machines for fully automatic burgers manufacturing in 2012 , but they have not yet been on sale.

Momentum Machines for fully automated burgers

Performance Flippy is 150 burgers per hour, according to Miso Robotics. Creating a Flippy and learning system took about two years. The company emphasizes that due to the built-in AI system and interchangeable tools, Flippy will eventually master frying and other dishes, including chicken, bacon, onion ringlets and other things that are usually offered to visitors of such restaurants.

At a cost of $ 60,000 and an approximate salary of a low-skilled worker of $ 10 per hour, it turns out that Flippy will pay for itself in about 2 years, 10 months and 20 days with 8 hours of work per day. If you count the time of work in two shifts, then payback comes twice as fast. This is a very good ROI. In China, robots are put instead of workers with a salary much less, because robots are still more profitable.

According to the developers, Flippy will really help the company save money. Savings are made not only on the salary of the cook, but also on reducing the additional costs associated with the frequent rotation of personnel. Work at the grill is dirty, greasy and physically hard, so there is a large turnover of personnel. New employees have to first be trained at the expense of the company, but the robot is working better and better every day - and for free, except for the costs of electricity and after-sales service.

From March 5, 2018, Flippy began work at the CaliBurger restaurant in Pasadena, and in the future the company plans to install similar robots in other restaurants of the chain. CaliBurger has the exclusive right to use Flippy for the next six months. Then others will be able to buy them.

Source: https://habr.com/ru/post/410685/