The development of CAD, what do we get?

My engineering practice made me work with very different CAD products (ProE, UG, SolidW, Revit, Advance steel, AutoCAD, MachCAD, SCAD). I use some of the tools all the time, others from time to time if asked to do a test or analysis. Knowledge of the design tool is primarily an understanding of the logical language of the program, and if you own several programs, then the rest is not difficult, since in fact only the icons and their location change. The more programs you know, the more specific tasks you can solve. The ten-year practice of using CAD has allowed me to make some idea of their development, and actually wanted to share this.

CAD systems can be divided into 3 levels according to their internal logic and functionality:

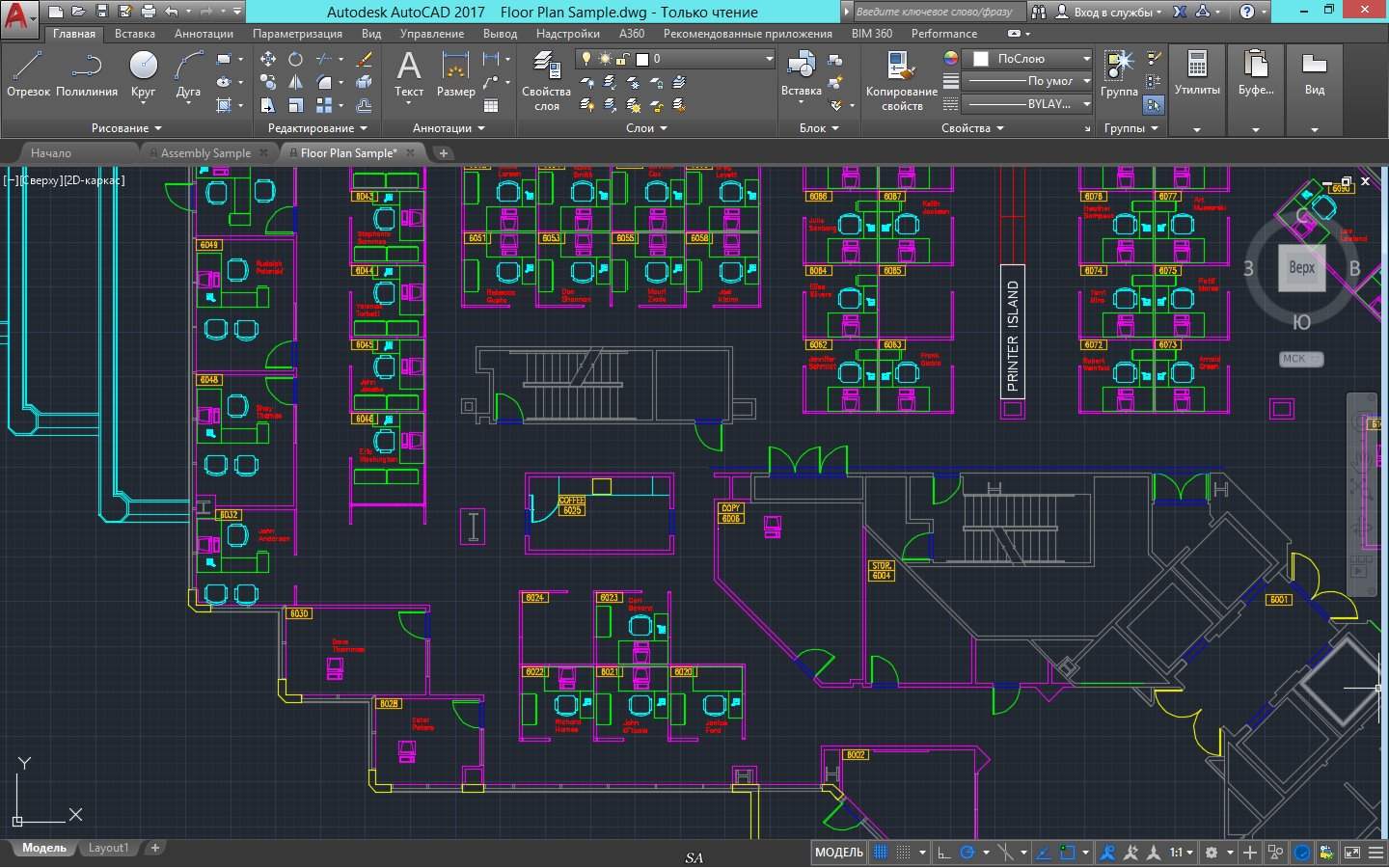

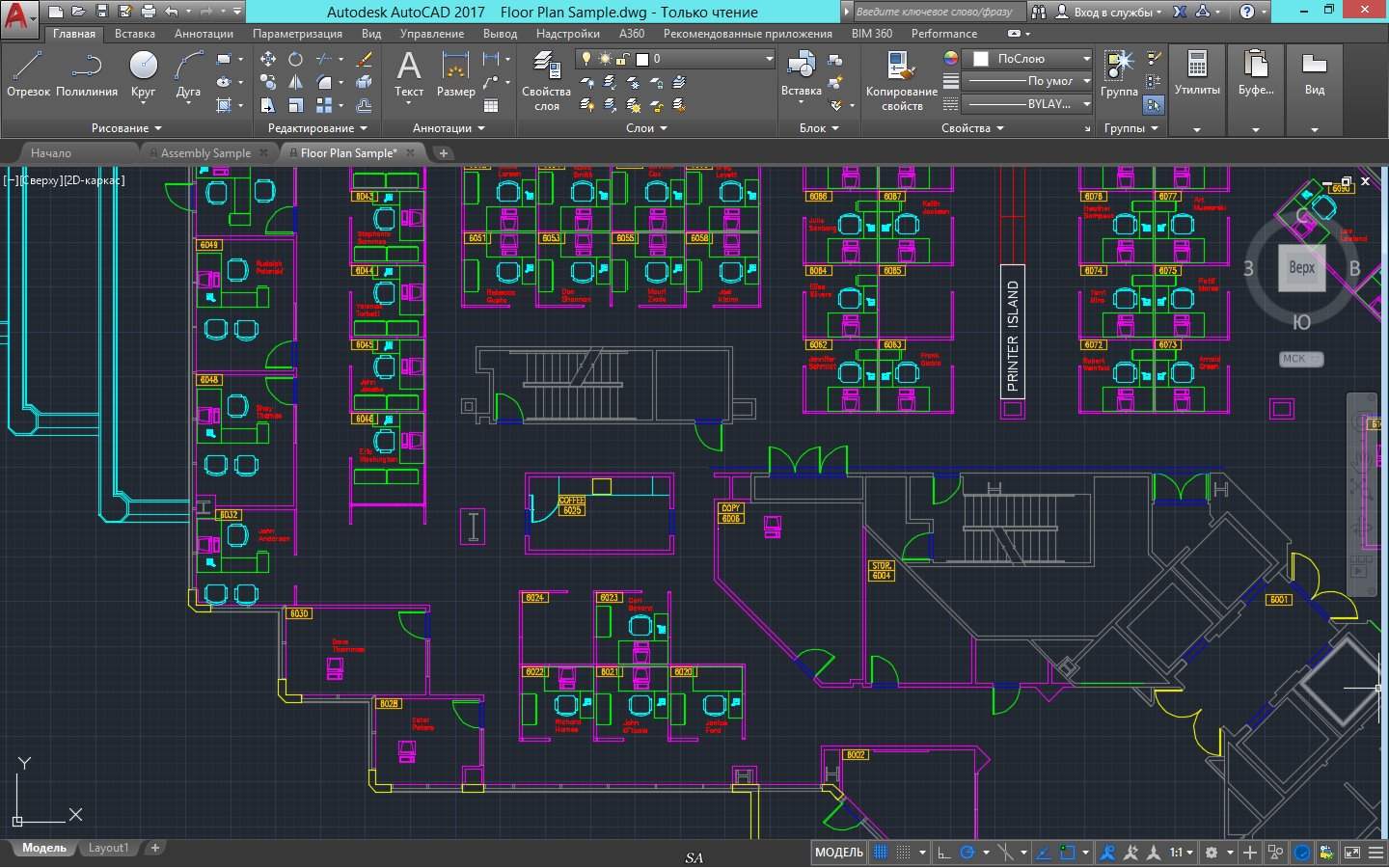

- Low-level systems with a closed mathematical model of constructions. This is a draftsman. Their logic is very simple - you take, in fact, a pencil and draw only not on paper, but in a vector space. All the logic of the construction comes solely from your considerations. In order to work in these programs you should decide on the size of the objects, their characteristics and geometry. Those. All drawing is reduced to multiple iterations (fittings) of the drawing under the conceived image. Of course, all this leads to a huge number of errors. However, the use of various smart templates for typical tasks (planning of premises, metal structures) greatly simplify this method of drawing.

For example, the template SPDS is well suited to comply with GOST and SNiP. These design systems (AutoCAD, Compass, Sketchup, etc.) are more suitable for building drawings, where most of the rules and regulations are already written and, in fact, the entire design space revolves around already invented nodes, links, sections, etc. All this gave rise to a new approach to design - this is BIM technology, it should be removed from the framework, since its logic is very different from other design systems. About her a little later.

- Mid-level systems (the most famous is SolidWorks, although in recent years it has almost reached high-level systems, as well as Invertor, etc.). They have an open mathematical model (model tree). Those. at any drawing stage you can track the previous construction steps. These systems are fundamentally different in their logic from the lower level systems. Here you work, as if with solids. Those. in the mathematics of the model lies the integrity of the geometry of the objects of construction and any intersection or non-compliance of "hardness" is impossible. Hence the term "solid modeling". In fact, working in these programs, the engineer handles electronic copies of these models, which allows you to apply assembly logic to the design. As it will happen in production, it should be implemented in the model. This removes a huge number of problems and reduces the number of errors in the design. However, the engineer himself in this case requires a wide range of knowledge in the area of requirements for the design object. These systems have made a significant step towards reducing the laboriousness of the design work compared to the first level systems, but did not solve the issue of optimizing products for the parameters, this was done by the highest level systems.

- Higher level systems with an open mathematical model of constructions with the possibility of end-to-end analysis of the model according to established criteria (strength, manufacturability, geometric constraints, etc.). The full capabilities of these systems are used only by very advanced users and, as a rule, only in industries with high constraints and complex tasks (aeronautical, aerospace, nuclear, etc.). Those. These systems are the cutting edge of design systems. They are the most advanced and complex. Their complexity lies in the fact that when modeling the program “forces” you to clearly define the connection of geometric objects. Those. Before you realize your plans in a 3D model, you must at least approximately represent the elementwise nature of the product. Each model is characterized by at least three binding reference dimensions (sketch plane, sketch depth and the size of the sketch itself), each positioning (assembly) - at least three connected surfaces or generators. For a product of 10 assembly units, the minimum number of defining links is 90 (10x3x3). In practice, there are always more. In this regard, in order for everything to come together correctly, it is very important to correctly build the connections of the objects, taking into account the enormous number of parameters (strength, operation, gatherability, adaptability). All this makes you think and think hard, but a well-built model is adaptable — it can be easily changed depending on the appearance of new requirements or restrictions. It is these systems, provided they are correctly simulated, that allow to optimize the product to the maximum by a huge number of parameters. This type of products includes three software packages: Unigraphics (NX), ProEngineer, Catia. The logic of these three systems is very similar, so the choice of which one usually comes down to personal convenience.

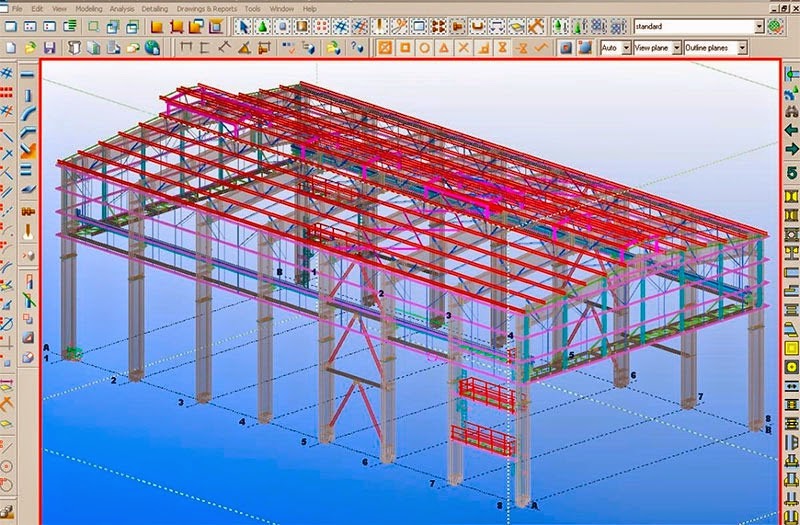

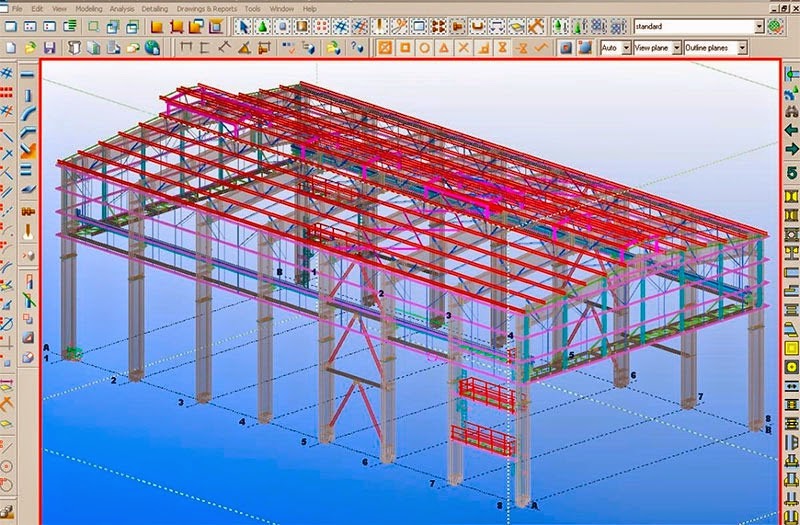

And finally, BIM systems. This is a fundamentally different approach to design. In fact, BIM systems are structured libraries of possible solutions that are tied to design objects. Those. Each design object has a certain set of parameters and characteristics that are already embedded in it and the user only needs to select these parameters from the proposed libraries depending on the purpose of the element or customer requirements. These systems include Revit, Advance steel, Tekla structures. These systems greatly simplify life and somewhat reduce the requirements for the qualification of an engineer, since they themselves already imply solutions to design problems. In fact, the work in these programs is reduced to the correct determination of design parameters from the proposed libraries. These systems are convenient for building objects, as the volume of libraries of building solutions is not large. What these systems lack is a normal analysis of the requirements of strength and stability. For the analysis of design solutions it is still convenient to use other software products (Lira, SCAD).

This is a real design system, but what awaits us in the future? The main task of CAD systems is to reduce design time. In this regard, all modern systems are superior kulman and slide rule hundreds of times. Three main tools are used for this:

- Creating a library of solutions within the limitations, norms and rules of design.

- Creation of adaptive end-to-end models capable of adaptation.

- Creation of communicative design environments (Windchill or Teamcenter, etc.).

All this has allowed to minimize the time for designing and upgrading products.

However, these systems are good if they are used in an enterprise with their “school”, i.e. with its decision base, requirements for geometry, technology and other restrictions. If within the framework of the existing system of design and production you decide to create something fundamentally new, you will encounter enormous difficulties, you will have to change the “school”, and this is very difficult. Those. it should be very clearly understood that it is precisely the limitations in design that make it possible to develop sustainable principles and recommendations for design. Which in turn limits the field of possible solutions. Otherwise, the system is reduced to a high degree of uncertainty, which the human mind simply cannot resolve, but it is in it that the most effective technical solution can be found.

In fact, now the human mind has reached the limit of application as the main generator of design thought. This happened because our thinking is limited by the number of logical solutions that we are capable of analyzing. On average, a person is able to calculate the consequences of decisions in three steps, then decisions with a high degree of uncertainty lie.

To expand these limits allow mathematical models to build long software links. Those. design turned into programming, only instead of the code, the physical parameters of the environment, the design object itself and its operational requirements are used. This allows you to spend a huge number of iterations in search of the optimal solution. However, this approach has also exhausted itself in the way that mathematical models are still built on the general ideas of a person about how to be true.

Thus, all design solutions are limited to the ideas of engineers about what they should be, and not the most optimal under these conditions. Those. design solutions are limited to the technology and inertia of thinking of the design participants. The advent of 3D printing dramatically expanded the boundaries of technology and provided an opportunity to create unique products. As soon as the restriction on the technological form of the part was lifted, systems for searching for optimal forms by load or other parameters appeared. However, the form and material is not yet a comprehensive solution to the design problem, but only local optimization.

So where should design systems go? Since the main customer of complex design work is large companies, and large companies are striving to reduce costs, then, of course, the main order for developers is the following:

- Deep integration of design and production (to reduce design errors relative to technological solutions).

- Equipment design in conjunction with product design. In fact, it all comes down to the fact that new high-quality optimal solutions are possible only if their production technology changes. Those. in parallel, two design processes, the machine tool and the product itself, must be conducted.

- Application of AI to go beyond the "school" of design. Those. AI systems should be used to:

- at the first stage - the selection of template design solutions and their optimization within the framework of the existing enterprise solutions.

- exit from template solutions in the direction of combining templates.

- Transition from combining patterns to creating new flexible design models.

In fact, designing will eventually lose a human face in terms of engineering tasks, and will begin to resemble programming more, i.e. physical and solid models will disappear altogether, and a mathematical complex of solutions will be immediately created within the framework of the mathematical design environment. The task of a person will be reduced to the compilation of the most complete and informative technical assignments, everything else should be done by the software itself.

Perhaps it seems utopian. But now I had to use elements of this not distant future. For example, I had a task within the framework of technological limitations to make a model of a composite wing. I did a mathematical model in MachCAD, a parametrized model in ProE, linked these files directly and through macros and received drawings that worked in a certain range of geometric values. Thus, this model for future users is a black box.

The user could simply choose the type of profile, scope, requirements for mechanization, and at the output received wing drawings. In this case, I myself was more a programmer than an engineer. If we could include advanced technology and optimization systems in this scheme, we would get a product of the future, but, of course, this is not an easy task.

The development of CAD should be aimed at eliminating human error factors from design systems. Of course, AI will cope with the design task more efficiently. But this development has a huge number of contradictions from ethical to economic. Imagine if all the Tupolev or Sukhoi design bureaus can be replaced by a group of programmers and analyst engineers — job loss, “what if everything breaks,” “what if a nuclear explosion, and we’ll get the kulmans from the basement ...”. These contradictions are systemic in nature and practically unsolvable. I think we will not see a truly new design system yet. The releases of all the programs mentioned above contain less and less qualitative changes and more boil down to the convenience of using and upgrading existing templates.

And finally, I would like to point out one very complex and obvious problem of the Russian design school - it still does not have its own top-level software package. Europe has the NX and Catia in the US - ProE - it’s not just software that is the epitome of the design school and ideas about the design automation process. And, of course, from the Russian developers, I would like to get a system that will immediately be a step ahead, something that we can usually catch up with.

CAD systems can be divided into 3 levels according to their internal logic and functionality:

- Low-level systems with a closed mathematical model of constructions. This is a draftsman. Their logic is very simple - you take, in fact, a pencil and draw only not on paper, but in a vector space. All the logic of the construction comes solely from your considerations. In order to work in these programs you should decide on the size of the objects, their characteristics and geometry. Those. All drawing is reduced to multiple iterations (fittings) of the drawing under the conceived image. Of course, all this leads to a huge number of errors. However, the use of various smart templates for typical tasks (planning of premises, metal structures) greatly simplify this method of drawing.

For example, the template SPDS is well suited to comply with GOST and SNiP. These design systems (AutoCAD, Compass, Sketchup, etc.) are more suitable for building drawings, where most of the rules and regulations are already written and, in fact, the entire design space revolves around already invented nodes, links, sections, etc. All this gave rise to a new approach to design - this is BIM technology, it should be removed from the framework, since its logic is very different from other design systems. About her a little later.

- Mid-level systems (the most famous is SolidWorks, although in recent years it has almost reached high-level systems, as well as Invertor, etc.). They have an open mathematical model (model tree). Those. at any drawing stage you can track the previous construction steps. These systems are fundamentally different in their logic from the lower level systems. Here you work, as if with solids. Those. in the mathematics of the model lies the integrity of the geometry of the objects of construction and any intersection or non-compliance of "hardness" is impossible. Hence the term "solid modeling". In fact, working in these programs, the engineer handles electronic copies of these models, which allows you to apply assembly logic to the design. As it will happen in production, it should be implemented in the model. This removes a huge number of problems and reduces the number of errors in the design. However, the engineer himself in this case requires a wide range of knowledge in the area of requirements for the design object. These systems have made a significant step towards reducing the laboriousness of the design work compared to the first level systems, but did not solve the issue of optimizing products for the parameters, this was done by the highest level systems.

- Higher level systems with an open mathematical model of constructions with the possibility of end-to-end analysis of the model according to established criteria (strength, manufacturability, geometric constraints, etc.). The full capabilities of these systems are used only by very advanced users and, as a rule, only in industries with high constraints and complex tasks (aeronautical, aerospace, nuclear, etc.). Those. These systems are the cutting edge of design systems. They are the most advanced and complex. Their complexity lies in the fact that when modeling the program “forces” you to clearly define the connection of geometric objects. Those. Before you realize your plans in a 3D model, you must at least approximately represent the elementwise nature of the product. Each model is characterized by at least three binding reference dimensions (sketch plane, sketch depth and the size of the sketch itself), each positioning (assembly) - at least three connected surfaces or generators. For a product of 10 assembly units, the minimum number of defining links is 90 (10x3x3). In practice, there are always more. In this regard, in order for everything to come together correctly, it is very important to correctly build the connections of the objects, taking into account the enormous number of parameters (strength, operation, gatherability, adaptability). All this makes you think and think hard, but a well-built model is adaptable — it can be easily changed depending on the appearance of new requirements or restrictions. It is these systems, provided they are correctly simulated, that allow to optimize the product to the maximum by a huge number of parameters. This type of products includes three software packages: Unigraphics (NX), ProEngineer, Catia. The logic of these three systems is very similar, so the choice of which one usually comes down to personal convenience.

And finally, BIM systems. This is a fundamentally different approach to design. In fact, BIM systems are structured libraries of possible solutions that are tied to design objects. Those. Each design object has a certain set of parameters and characteristics that are already embedded in it and the user only needs to select these parameters from the proposed libraries depending on the purpose of the element or customer requirements. These systems include Revit, Advance steel, Tekla structures. These systems greatly simplify life and somewhat reduce the requirements for the qualification of an engineer, since they themselves already imply solutions to design problems. In fact, the work in these programs is reduced to the correct determination of design parameters from the proposed libraries. These systems are convenient for building objects, as the volume of libraries of building solutions is not large. What these systems lack is a normal analysis of the requirements of strength and stability. For the analysis of design solutions it is still convenient to use other software products (Lira, SCAD).

This is a real design system, but what awaits us in the future? The main task of CAD systems is to reduce design time. In this regard, all modern systems are superior kulman and slide rule hundreds of times. Three main tools are used for this:

- Creating a library of solutions within the limitations, norms and rules of design.

- Creation of adaptive end-to-end models capable of adaptation.

- Creation of communicative design environments (Windchill or Teamcenter, etc.).

All this has allowed to minimize the time for designing and upgrading products.

However, these systems are good if they are used in an enterprise with their “school”, i.e. with its decision base, requirements for geometry, technology and other restrictions. If within the framework of the existing system of design and production you decide to create something fundamentally new, you will encounter enormous difficulties, you will have to change the “school”, and this is very difficult. Those. it should be very clearly understood that it is precisely the limitations in design that make it possible to develop sustainable principles and recommendations for design. Which in turn limits the field of possible solutions. Otherwise, the system is reduced to a high degree of uncertainty, which the human mind simply cannot resolve, but it is in it that the most effective technical solution can be found.

In fact, now the human mind has reached the limit of application as the main generator of design thought. This happened because our thinking is limited by the number of logical solutions that we are capable of analyzing. On average, a person is able to calculate the consequences of decisions in three steps, then decisions with a high degree of uncertainty lie.

To expand these limits allow mathematical models to build long software links. Those. design turned into programming, only instead of the code, the physical parameters of the environment, the design object itself and its operational requirements are used. This allows you to spend a huge number of iterations in search of the optimal solution. However, this approach has also exhausted itself in the way that mathematical models are still built on the general ideas of a person about how to be true.

Thus, all design solutions are limited to the ideas of engineers about what they should be, and not the most optimal under these conditions. Those. design solutions are limited to the technology and inertia of thinking of the design participants. The advent of 3D printing dramatically expanded the boundaries of technology and provided an opportunity to create unique products. As soon as the restriction on the technological form of the part was lifted, systems for searching for optimal forms by load or other parameters appeared. However, the form and material is not yet a comprehensive solution to the design problem, but only local optimization.

So where should design systems go? Since the main customer of complex design work is large companies, and large companies are striving to reduce costs, then, of course, the main order for developers is the following:

- Deep integration of design and production (to reduce design errors relative to technological solutions).

- Equipment design in conjunction with product design. In fact, it all comes down to the fact that new high-quality optimal solutions are possible only if their production technology changes. Those. in parallel, two design processes, the machine tool and the product itself, must be conducted.

- Application of AI to go beyond the "school" of design. Those. AI systems should be used to:

- at the first stage - the selection of template design solutions and their optimization within the framework of the existing enterprise solutions.

- exit from template solutions in the direction of combining templates.

- Transition from combining patterns to creating new flexible design models.

In fact, designing will eventually lose a human face in terms of engineering tasks, and will begin to resemble programming more, i.e. physical and solid models will disappear altogether, and a mathematical complex of solutions will be immediately created within the framework of the mathematical design environment. The task of a person will be reduced to the compilation of the most complete and informative technical assignments, everything else should be done by the software itself.

Perhaps it seems utopian. But now I had to use elements of this not distant future. For example, I had a task within the framework of technological limitations to make a model of a composite wing. I did a mathematical model in MachCAD, a parametrized model in ProE, linked these files directly and through macros and received drawings that worked in a certain range of geometric values. Thus, this model for future users is a black box.

The user could simply choose the type of profile, scope, requirements for mechanization, and at the output received wing drawings. In this case, I myself was more a programmer than an engineer. If we could include advanced technology and optimization systems in this scheme, we would get a product of the future, but, of course, this is not an easy task.

The development of CAD should be aimed at eliminating human error factors from design systems. Of course, AI will cope with the design task more efficiently. But this development has a huge number of contradictions from ethical to economic. Imagine if all the Tupolev or Sukhoi design bureaus can be replaced by a group of programmers and analyst engineers — job loss, “what if everything breaks,” “what if a nuclear explosion, and we’ll get the kulmans from the basement ...”. These contradictions are systemic in nature and practically unsolvable. I think we will not see a truly new design system yet. The releases of all the programs mentioned above contain less and less qualitative changes and more boil down to the convenience of using and upgrading existing templates.

And finally, I would like to point out one very complex and obvious problem of the Russian design school - it still does not have its own top-level software package. Europe has the NX and Catia in the US - ProE - it’s not just software that is the epitome of the design school and ideas about the design automation process. And, of course, from the Russian developers, I would like to get a system that will immediately be a step ahead, something that we can usually catch up with.

Source: https://habr.com/ru/post/410699/