Software AG: not only ARIS

Hello, Habr . My name is Oleg Poretsky. I am Vice President of Software AG Sales in Russia and the CIS. We have been working in Russia since the 80s, and we have something to tell about ourselves.

In the English segment, we support our own IT professional community (TECH Community). Now it is time to join the Russian-speaking community. We will consider this post our acquaintance.

Many have heard of Software AG only in the context of ARIS, but in fact our company is not the “author of one product.” Moreover, ARIS is not even our first product.

I will talk about eight of our key tools that are used in a wide variety of areas - from washing rugs and cleaning bathrooms ( CWS-boco ) to critical calculations for the hadron collider ( CERN ), from managing strategic coffee stocks in a distributed network of corporate coffee machines ( Lyreco ) to gas distribution in the country ( Gaz-System SA ).

Adabas in the CPSU Central Committee

Our very first software product was Adabas DBMS - a platform for processing data with ultra-high performance. When the Soviet Union, it accounted for 85% of the Soviet database market. On the basis of Adabas, information systems of the government of the country, including the Central Committee of the CPSU, were built; therefore, several research institutes at once sharpened Adabas DBMS for domestic computers.

If you heard about DISOD and TRIAD , these are the domestic analogues of our Adabas.

webMethods to Nissan

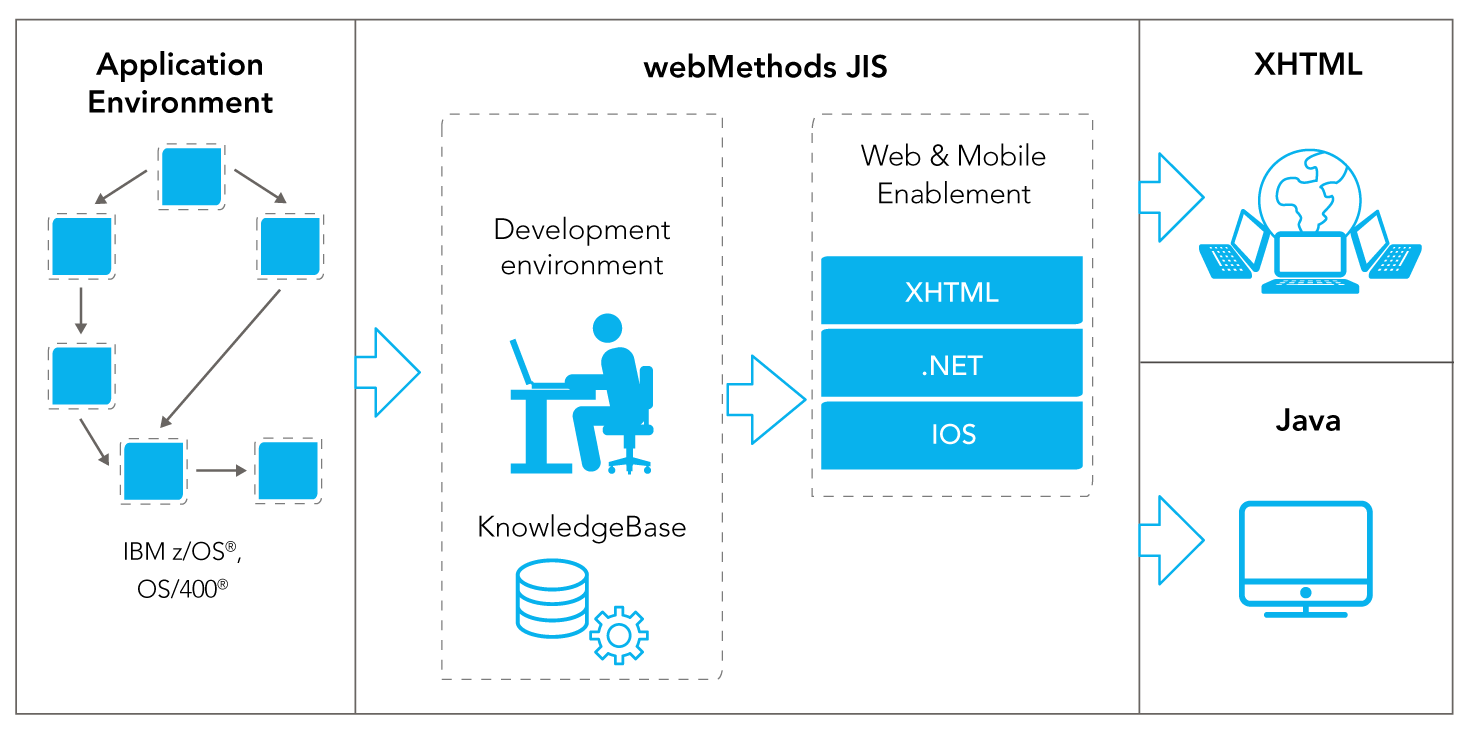

Sometimes, in addition to Adabas, customers need additional tools - the business is developing, and new tasks are emerging. Recently, we were approached by Western colleagues from Nissan, whom our platform has been serving since they opened their flagship factory in the UK in the 80s. Adabas got along pretty well on their mainframes - today, Nissan's business processes are tied to it, starting with the purchase of raw materials for production and ending with the sale of finished cars. This time, we were faced with another task - “making friends” of the mainframe's green screens with modern SOA applications. They did not want to alter the backend system, but they needed the ability to interact with it through a web interface.

The functionality of our webMethods platform for automating and monitoring business processes came up to solve this task. With the help of webMethods, colleagues from Nissan were able to optimize the supply chain. Now the raw materials needed for production are replenished automatically in real time: when stocks run out, the Nissan backend system running on Adabas mainframe directly sends requests to dealers via webMethods.

Alfabet in South Australia Vodokanal

Sometimes the company faces more ambitious tasks. For example, SA Water's water canal in South Australia needed to synchronize 40 large projects across the country to prioritize investment plans.

We offered to use Alfabet, our integrated platform for managing changes in the corporate architecture, which is unique in its ability to synchronize business goals and tasks with their corresponding architectural initiatives and IT projects. With her colleagues from SA Water were able to effectively combine:

- centralized information repository

- practical developments scattered throughout the enterprise,

- the ability to identify and fill information gaps,

- possibility of collective access to all this information.

Due to this, all units now have a “single point of truth” that allows you to create and successfully implement a holistic multi-year plan for the benefit of 1.6+ million residents of South Australia.

Terracotta and the Hadron Collider

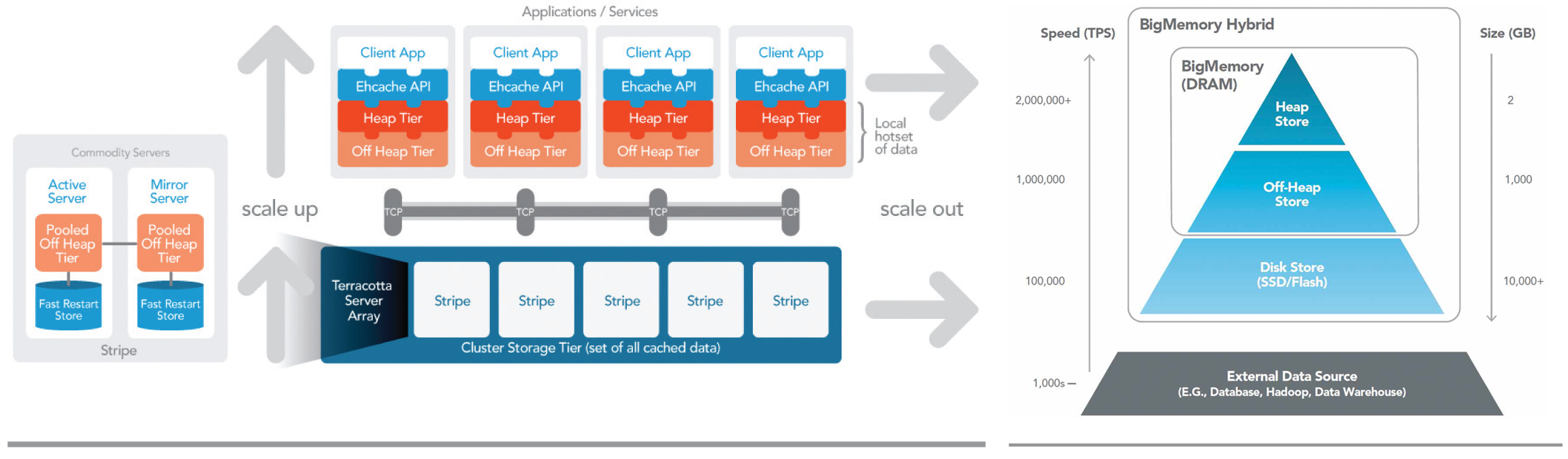

CERN, the world's largest high-energy physics laboratory with its own Large Hadron Collider, has set an even more challenging task for us. To work with it, CERN uses a technical infrastructure monitoring (TIM) platform, which processes data collected from 120,000 sensors in real time.

Terracotta is responsible for ensuring a high level of performance and availability of TIM, taking into account the enormous amount of data that has to be processed. This is our scalable data management platform hosted in the computer's RAM, which operates in real time with extremely low predictable latency.

Apama and Zementis in the service of accurate prediction of the time of arrival of ships

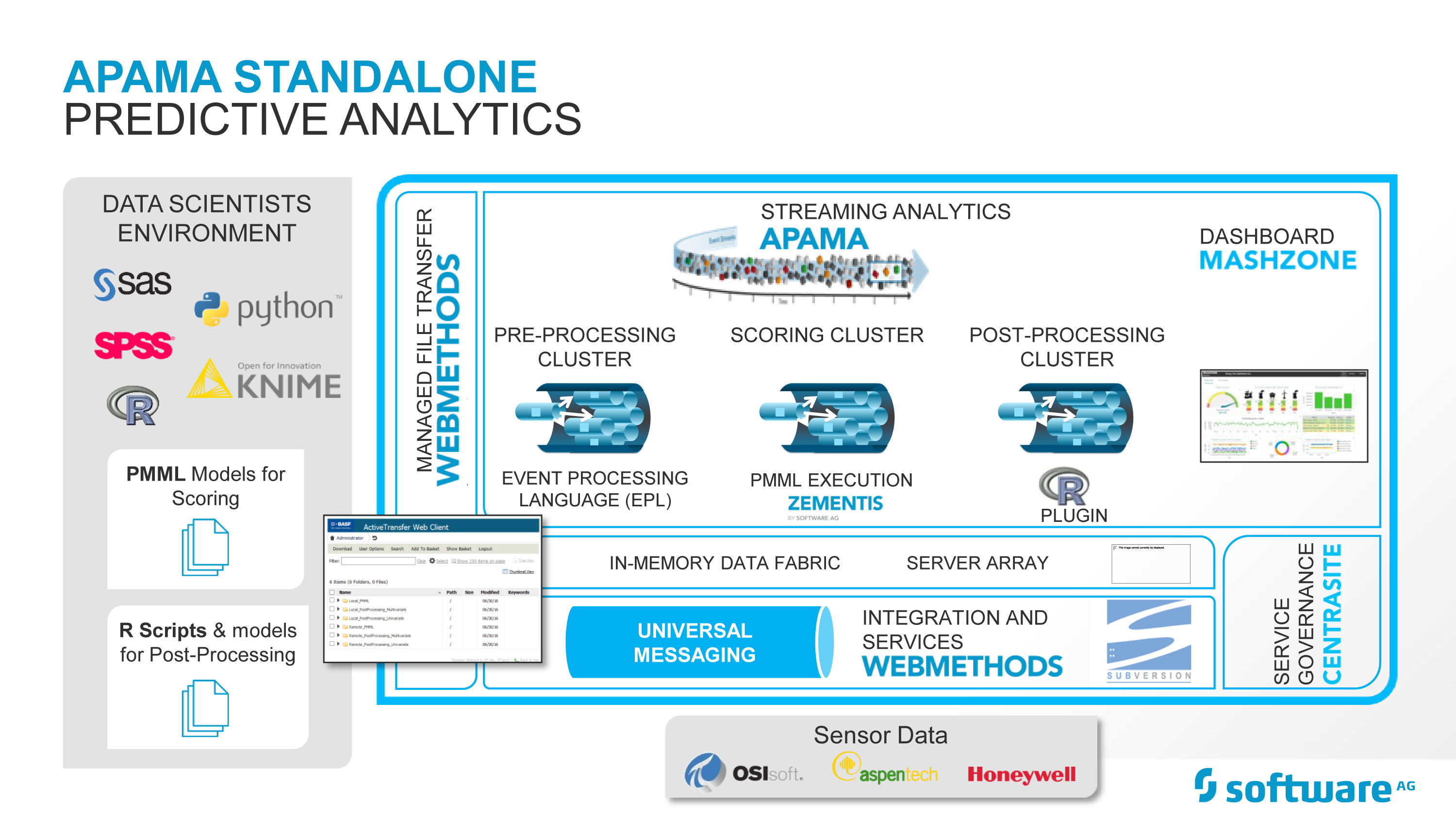

Sometimes the flow of disparate data is so large and so quickly updated that even the most powerful system can hang. With such a problem we were approached by the company Royal Dirkzwager. This is a provider of information on the arrival and dispatch of ships around the world. Some time ago, they decided to embody an ambitious idea: to provide their clients with accurate information about the estimated time of arrival of their ships at the port in real time. It seems to be nothing complicated - today, few people will be surprised by satellite navigation. But the problem is that for the realization of this idea, it was necessary to simultaneously track immediately 120 thousand ships, which transmit data about their location every two seconds.

“Our systems are choking on such a data flow,” said colleagues at Royal Dirkzwager, asking us for help.

We offered them a solution based on two of our tools: Apama (streaming analytics platform, which performs a comprehensive analysis of data flows from disparate systems, tracking and reacting to events occurring in them) and Zementis (rapid deployment platform for analytical models created using artificial intelligence). intelligence).

Now Royal Dirkzwager clients have the opportunity to adjust the time of arrival at the port to within a few minutes, which allows them to eliminate the costs associated with the premature or late arrival of ships to the port. It's about tens of thousands of dollars, so it was worth it.

Cumulocity IoT in the Nordex Group Wind Turbines

Since we are talking about savings, it is worth mentioning the companies operating in the field of energy-saving technologies. The Nordex Group, a global manufacturer of ground-based wind turbines, uses our Cumulocity IoT platform (a framework for working with the Internet of Things) to control its 6800+ wind turbines. Nordex through Cumulocity IoT offers customers comprehensive monitoring that allows them to optimize the performance of their wind turbines. By combining Cumulocity IoT with its wind turbines, Nordex can now create a remote control system and centralized monitoring in real time.

ARIS gas distribution in Poland

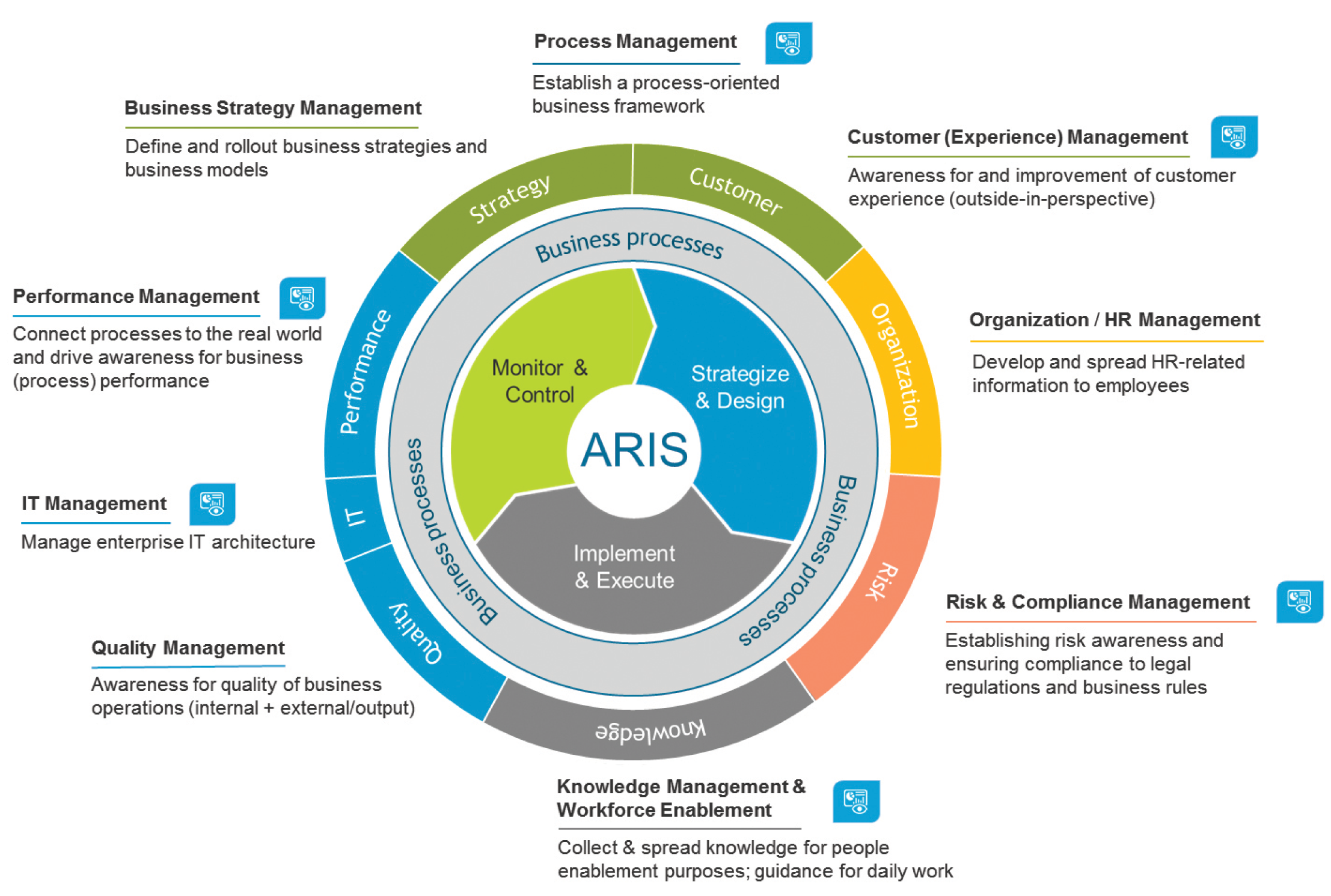

Finally, we come to our most famous product - the ARIS platform.

Our client Gaz-System SA transports gas through a system of pipelines covering the territory of Poland, and delivers it to local distributors and large industrial consumers. According to Polish law, Gaz-System SA is obliged to ensure equal and non-discriminatory access to the pipeline system for all market participants. This means not only providing an opportunity to enter into contracts and physically deliver fuel, but also to gain access to current information on actual and planned transmission volumes in certain parts of the pipeline system. And this is just a small list of puzzles that Gaz-System SA has to deal with.

Without automation and digitalization here is just no way. Therefore, Gaz-System SA some time ago went to ensure that automate their business processes through the SAP system. At the same time, the company’s management initially wanted to optimize their business processes and only then transfer them to SAP. Using our integrated ARIS platform for managing digital business transformation, colleagues from Gaz-System SA were able to optimize their end-to-end business processes to such an extent that their number decreased from 40 to 8.

“The introduction of SAP definitely would not have passed so smoothly if we had not first spent considerable time on modeling business processes,” admit colleagues at Gaz-System SA

So, colleagues, I told you about our eight key products and some of their uses. As you can see, Software AG has a lot of interesting things besides ARIS. If you want to see real-life examples of using our tools, welcome to our GitHub repository , as well as to the company's website.

Source: https://habr.com/ru/post/436498/