Want eternal LEDs? Uncover soldering irons and files. Or homemade home lighting

Once a long time ago, when I was still in school, and the yard was the end of perestroika, my uncle (who started to interest me in electronics) took the bag taken out through the factory good . Actually, such bags he brought home quite regularly, replenishing supplies stored in the sofa. This sofa, as you guess, beckoned, and sometimes in the absence of my uncle I looked into it with delight. But something from this bag did not fall into the sofa, but fell into my hands. My uncle handed me a pack - about ten - breadboard boards, and a new unopened box of scarce, and not cheap, LEDs at that time. And the LEDs were not simple: instead of the usual marking AL-something there was a four-digit code on the box, as I understood it - they were experimental. And they were bright. Compared with the usual AL307 or AL310 - just dazzling. And there were also a lot of them - 50 pieces.

The idea of “where to apply this wealth” appeared instantly: the LEDs were unsoldered on one of the layout holders — how many climbed (not all climbed), and from them came a magnificent red lantern for printing photos, which absolutely did not light up the photo paper even at the stop. True, I immediately learned that “the LEDs are not warming up” are lies, so the current had to be halved, from 10 mA to LED to 5. And after six months of successful operation I also learned that “the LEDs do not burn out "- this is also not true: the first LED in the assembly has gone out, it has been punched. And over time, the whole lantern fell into disrepair.

And now I hear again from each iron about the "eternal" LED bulbs, and at home for the incomplete year of switching to LED lamps, the third one has already burned out.

Why LED bulbs are not forever?

Yes, because nothing is eternal. The LED, besides - a piece thin. Literally. In its structure there are layers with a thickness of a few nanometers forming quantum wells. Diffusion and electromigration to such layers are ruthless - they erode them, create defects, gradually reducing light output and increasing the likelihood of a catastrophe on the scale of a tiny crystal, in which, by the way, light and heat energy is released, the specific value of which can be calculated per cubic centimeter pn junction Only compare with a nuclear explosion (a bit exaggerated, but estimate the energy density itself). The hotter the LED, all the negative processes will go faster. And he, as we already know, heats up. Heats even when a current of 10 milliamps flows through it. And even more so when it is a powerful device, the current through which is at least 100 mA, and sometimes it is amperes, and even three amperes. And in the heat, in spite of all the energy efficiency of the LEDs, a significant proportion of electricity supplied to the LED passes. Two thirds to three quarters.

And where to cool the LEDs in the LED light? And nowhere, by and large. The LED itself is designed so that it can be cooled. The crystal is soldered to a massive base of copper or high-conductive ceramics, this base has a special soldering platform for an external heat sink, in the role of which is a board with an aluminum or copper substrate. And this substrate, in theory, should be bolted to a good radiator with a large area through thermal paste. At best, it is screwed to the metal case of the LED lamp, the area of which is completely inadequate to dissipate more than a few watts of heat, and even in a closed ceiling. In the worst case, the casing is generally plastic, and heat from the driver and from a light that has not gone out and lost in the depths of the bulb still gets into this casing. Here the LEDs are roasting at a temperature exceeding 100 or even 130 ° C. And, by the way, not only the LEDs, but also the driver, which also often fails.

What to do?

One of the three. Either we, leaving the old chandelier in place, put in it smaller power bulbs. They will warm up less and have more chances to live for a long time. Of course, the room will become dark: we will return to the times when 25 watt light bulbs stood in the chandelier of economy and fire safety, which left them, putting in their place a fifteen-watt energy-saving light that made a dark room in which it was nice to be.

Or we buy a new chandelier, in which more light bulbs can be screwed. So we will stay with a bright room and get (possibly) a longer life of light bulbs. Only a chandelier, like a light bulb, will have to be spent.

And finally, the third option: we forget the very concept of "LED lamp", like a bad dream and put in place of the chandelier a specially designed LED lamp. Thoughtful and in terms of good use of luminous flux (for LED lamps like “hanging a pear - you cannot eat” with this in devices designed for incandescent bulbs, it is not always good - they are not good enough to shine sideways and back), and in terms of high-quality cooling.

Market

There are such fixtures on the market. But for the most part, they are first, expensive, and secondly, terrible. A sort of industrial gizmos that are appropriate in the garage, workshop, in the trading floor of the supermarket, in the office, finally - but not in the apartment. No, there are beautiful, and designer very spectacular-looking lamps. But - first, again, the price, and secondly, cooling was sacrificed to the design.

So, the classical Chinese LED chandelier-pancake is fifty watts of LEDs sitting on an aluminum board in the form of a ring with a diameter of 45 cm and a width of 8 centimeters. And that's all. No body with ribbing, nothing. And again, the board is in an almost tightly closed case. Well, at least the driver a little out. Verdict: life will be like an LED light. Only when they die will they have to change not a light bulb for 150 rubles, but a chandelier for five to ten thousand.

In general, the solution seems to be the same: skillful hands.

Homemade lamp: design

I must say: the lamp will not be on the LED strip and without bluetooth.

First, let's estimate how much light we need. It's a matter of taste, but I love it when it's light in the dwelling. I love every intimate twilight on special occasions, in a romantic setting, but in everyday life, he casts anguish. You can count everyone, but I will take advantage of the fact that with a chandelier with five energy savings of 15 watts, each giving 950 lm, the room was good. That is, 5 kilolumen will be enough for us. Now we go to the Cree website, we find there Datasheet on the CXA2530 modules. Why on them? Yes, because I have a few pieces of such modules, and it is convenient to work with them: they just solder the wires, and the modules themselves are planted directly on the radiator using the included flange. And they are easy to buy - a famous Chinese online store to help. In my existing modules bin T4 luminous flux, this corresponds to a nominal luminous flux of 3440-3680 lm. Immediately 20% of this figure we take away - they will be lost on the lens. We get a luminous flux of 2750-2950 lm, and given that this stream is obtained at a power of about 30 W, we get the power required for lighting (brought to the LEDs) about 50 W. Since our room is long, we will remove the chandelier from the center and make two identical lamps of 25 watts each.

Taking the efficiency of LEDs for 25% (a fairly conservative estimate is most likely better, but certainly not worse), we find out that 18.75 W of heat is generated in each luminaire. And our task is to choose a radiator for this heat dissipation. Here is how we do it.

We will proceed from the maximum crystal temperature.

What is the thermal resistance? Its first component is the thermal resistance inherent in the LED body itself. Cree does not give this value directly to the datasheet, offering to use a strange schedule, but in early publications in magazines about the release of new LED arrays indicated the value of 0.8 ° C / W.

The second component of the total thermal resistance is the resistance created by the layer of thermal paste between the housing and the radiator. As a thermal paste, we take the good old Alsil-3, with thermal conductivity

So, we still have 1.1 ° C / W on the radiator. Based on this figure, we choose a radiator, throwing 30 percent "on lies", on the spread of heat from the small matrix and on the fact that the radiator will be non-optimally oriented in space. For example, we can use the ABM-076 profile with a section size of 176x40 mm with a thermal resistance of a piece with a length of 100 mm 0.5 ° C / W. We have enough pieces of this profile with a length of 80-100 mm. 100 mm are standard pieces available on the market, 80 must be ordered from the manufacturer (Virtual Mechanics, virtumech.ru ), this option looks somewhat more aesthetic at the expense of a smaller width.

It remains to choose a driver. The criteria for choosing it is the current and operating limits of the output voltage. A power of 25 W is obtained at a current of about 0.7 A, the voltage on the matrix will be about 35-36 V.

Design

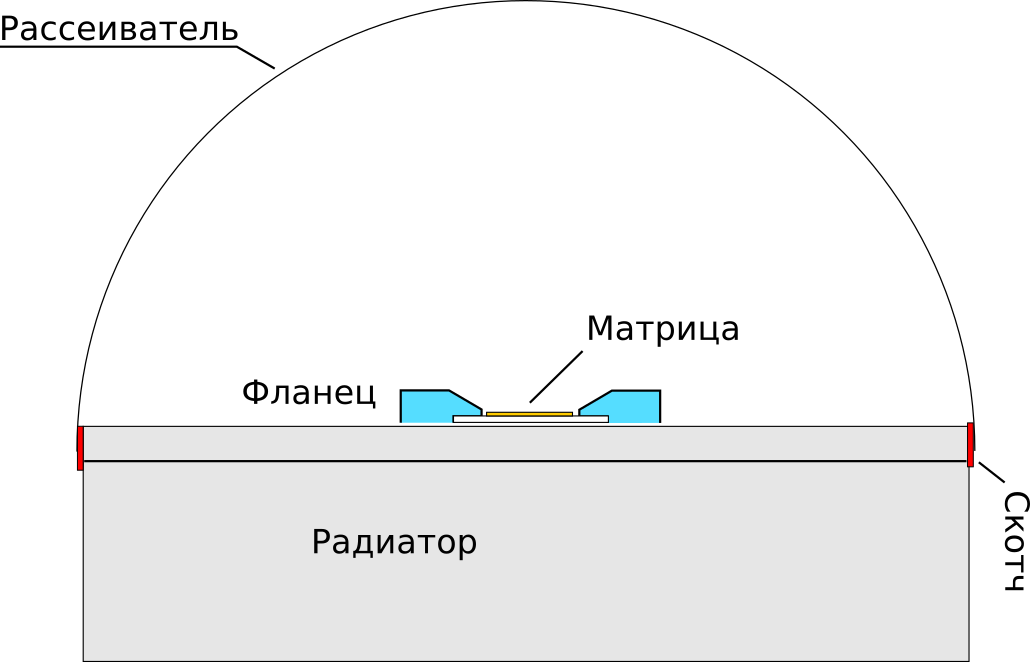

After going through several versions of the design of the lamp, I stopped at the diffuser of matte translucent plastic, having the form of a half-cylinder. This form is obtained in the simplest way - by attaching a curved plate to the sides of the radiator. The mounting method is rather arbitrary - on screws with pressure plates, on glue - I used the red double-sided tape “Moment”. I used a diffusing film from the backlight of a broken LCD monitor as a diffuser - it has very good light transmission. You can also mate with an abrasive film for printing on a laser printer or any other thick plastic film.

A matrix with pre-soldered wires is installed using the complete flange in the center of the radiator using two M3 screws (it is inconvenient to use nuts, so you have to work with a tap). Before gluing the diffuser, it is recommended to glue the flat surface of the radiator free from the matrix with aluminum tape or paint it with white paint - this will reduce the loss of light.

Regarding thermal paste - I would like to note that the use of dark thermal paste is not recommended: it will reduce the luminous flux by 10 percent. I noticed it well in two copies, one of which I did with Alsil-3, and the second one did not have enough alsil and I used the paste from the Scythe cooler kit, which had a dark gray color. The difference in measurement with a light meter is obvious. Also, it makes no sense to use more expensive than alsil thermal paste with a higher thermal conductivity: even at a couple of degrees, even at alsil, they will not make the weather.

After assembling the first luminaire (in which I used the radiator from the Pentium II processor and who settled in the kitchen, it has a slightly lower power in the region of 15 W), I decided to put not one matrix in the lamps for the room, but two “smeared” spot light on the diffuser and made the light more comfortable. In this case, it would be more reasonable to install less powerful modules, say, CXA1820. The modules were connected in parallel, this did not cause undesirable consequences in the form of an uneven distribution of current between them - both matrices glow the same way. But I leveled the length of the leads.

My ceiling mount is made using a rocker arm made of hard steel wire 2 mm in diameter, the ends of which are threaded into the holes in the extreme radiator fins and bent. A hook attached to the ceiling is hooked to the center of the rocker arm, so long as there is a couple of centimeters between the stretch ceiling and the radiator. The driver is hidden behind the stretch ceiling. If the lamps were made to the ceiling, it would be possible to hide radiators in it.

The surface of the radiator can be painted black with a permanent marker or with a thin layer of spray (thick is not necessary - thermal insulation). And you can not paint, his eyes are not particularly corn.

results

Light Under the lamps at the height of the tabletop - 450 lux, in the middle of the room 380 lux. The light is comfortable, the color rendition is quite (true, in the kitchen it turned out that raw meat under this light looks like it was tinted slightly with blueberry juice). Radiators after hours of work are warm, but not hot. Flicker is zero (merit quality drivers).

And at prices: the matrix cost 550 rubles each (the course has since changed, of course), radiators 600 rubles each, drivers 250 rubles each, the film went for free. Total - 2200 + 1200 + 500 = 3900 rubles. Plus two or three hours of work.

Source: https://habr.com/ru/post/437420/