Who is most effective in distributing printed circuit boards?

Let us recall how the responsibilities of specialists in the electronics industry were distributed 40 years ago. The process was divided into two main stages, the first of which was the development of schematic diagrams, and circuit engineers were engaged in this (and are still engaged). Much has changed since then, but the essence remains the same.

At that time, circuit diagrams were composed of discrete components — resistors, capacitors, diodes, transistors, and so on. However, electronics engineers who designed such circuits were not required to take into account the physical dimensions of the components: they were only interested in technical characteristics.

In universities, the future engineers of this specialty were taught circuitry. In the course of practical training, they modeled their devices on breadboard boards, and only one unit had to deal with the layout of printed circuit boards - those who needed it in their graduation projects.

The second stage of the development process of electronic devices is the implementation of circuits on printed circuit boards. As already mentioned, the circuitry could not do it, and the designers of the boards were connected to the case. The work was carried out mainly by hand, and the boards themselves were made by etching.

In the 70s, the use of integrated circuits (ICs) began to gain momentum. Plus was the miniaturization of devices, but at the same time there was a problem with the trace, as the density of tracks on the board increased.

By the end of the 80s, when IPs were used everywhere, the etching method showed its inefficiency, so the industry headed for multilayer printed circuit boards. Accordingly, both the circuit engineers and the designers of the boards had to take up the development of CAD systems for electronics - otherwise the industry would not recover for a long time from subsequent economic crises.

And now we turn to the results of recent surveys. More than 75 percent of designers of printed circuit boards have already crossed the age of 45 years, and half of them plan to retire in the next 10 years. What does this mean for the industry?

In fact, a vacuum has arisen in the electronics industry. Circuit engineers do not plan to design boards - they are more interested in the development of circuit diagrams and writing firmware.

But in reality, boards are just as much a concern for hardware designers. Here the electrical and mechanical components are closed, and what we call mechatronics is formed.

The development of schematic diagrams with power, analog and digital components is still under the jurisdiction of circuit engineers, but we will not exclude that in the future universities will begin to train specialists in mechatronics.

Designers of electronic devices may well take over the baton from the designers of printed circuit boards, and here's why:

Libraries. In the design of boards, one of the main factors is the consideration of the contour of the element. It is also necessary to take into account the location of the findings in order to correctly dissolve the tracks and take into account all the necessary tolerances.

Such nuances are unknown to the circuit design engineer, and the designers of electronic products are very well aware of them. In addition, we should not forget about the height of each particular element, which is important for their proper placement on the board.

Form of payment. The marketing services are becoming more and more actively involved in the process of assembling boards - after all, they have the decisive voice in determining the shape of products, and designers have to take this into account.

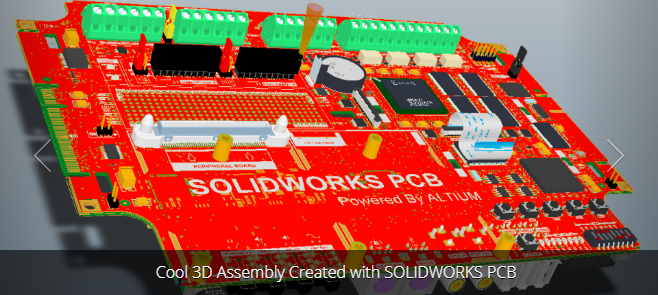

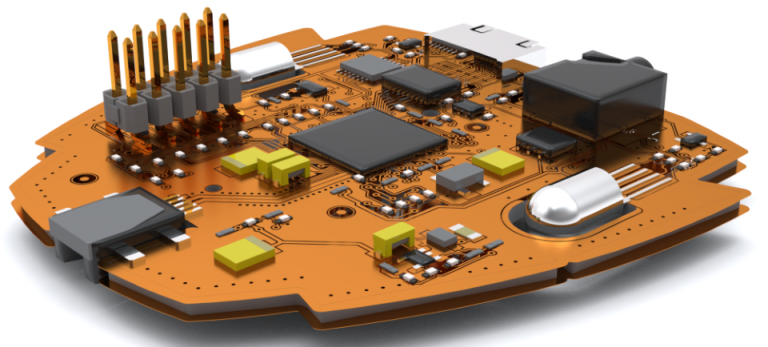

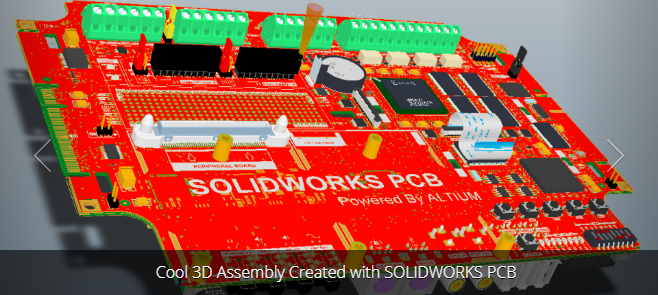

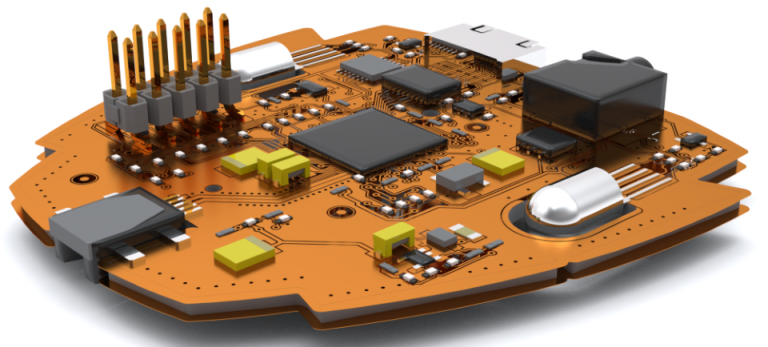

In the past, industry and consumers were completely satisfied with rectangular-shaped printed circuit boards that echoed the shape of the product cases. More precisely, the dimensions of the cases were adjusted to the boards that were placed inside. But with the development of design systems, the restrictions have disappeared, and the forms can be arbitrary. Now, on the contrary, the boards are designed to fit into the housing designed by the designers.

Placement of items. Here the design and marketing component is gaining more and more weight. The board, together with the components, is transferred from the design to the circuit design system and back to achieve maximum ergonomics from the product. It should be convenient for the user to press the buttons, set the switch positions, connect the cables and observe the displays and LEDs. Here again we can talk about mechatronics, since in real time there is a parallel development of electronic and mechanical parts. This allows for the correct placement of the board and the components on it, so that conflicts do not occur between them and the body of the product.

Monitoring compliance with the rules. The rules determine, in particular, the gaps between the tracks, the distances between the elements, the width of the tracks, the diameters of the holes and the dimensions of the contact pads. Some of these parameters reflect electrical requirements (primarily in power and high-frequency devices); others proceed from the manufacturability of production. The designer must know the theory of tolerances and be able to apply it in practice.

Layout One of the most serious tasks of the design of printed circuit boards is the routing of tracks, which requires engineers to have experience and qualifications. When teaching this process, the trial and error method is often practiced, so it is difficult to say which engineers will succeed in this. CAD developers understand the problem and try to include as many features as possible in their systems that automate the process. However, users of such CAD systems must have proper experience to work effectively.

Heat dissipation. The problems of heat removal are familiar to everyone, especially the developers of devices for difficult climatic conditions, power and high-frequency devices. Manufacturers of electronic and mechanical CAD systems have responded to this by adding analysis capabilities to their systems. However, the users themselves should be aware of the processes of heat transfer, and universities should attend to teaching the engineers of the relevant disciplines.

findings

We tried to show that the design of printed circuit boards - this is including the responsibility of designers of electronic devices. There are exceptions, and circuit design engineers are involved in the development of high-complexity boards, but in the general case, the task is quite accessible to designers with basic skills in working with CAD electronics.

In addition, it becomes clear that printed circuit boards are mechatronics, and they need to be designed while developing electrical and mechanical components. And in the future we are waiting for such revolutionary technologies as 3D printing, conductive pastes and embedded components. This means that the ways of production and the requirements for the qualifications of engineers will change. And circuitry, and designers will have to actively interact in the process of developing boards and product layout.

At that time, circuit diagrams were composed of discrete components — resistors, capacitors, diodes, transistors, and so on. However, electronics engineers who designed such circuits were not required to take into account the physical dimensions of the components: they were only interested in technical characteristics.

In universities, the future engineers of this specialty were taught circuitry. In the course of practical training, they modeled their devices on breadboard boards, and only one unit had to deal with the layout of printed circuit boards - those who needed it in their graduation projects.

The second stage of the development process of electronic devices is the implementation of circuits on printed circuit boards. As already mentioned, the circuitry could not do it, and the designers of the boards were connected to the case. The work was carried out mainly by hand, and the boards themselves were made by etching.

In the 70s, the use of integrated circuits (ICs) began to gain momentum. Plus was the miniaturization of devices, but at the same time there was a problem with the trace, as the density of tracks on the board increased.

By the end of the 80s, when IPs were used everywhere, the etching method showed its inefficiency, so the industry headed for multilayer printed circuit boards. Accordingly, both the circuit engineers and the designers of the boards had to take up the development of CAD systems for electronics - otherwise the industry would not recover for a long time from subsequent economic crises.

And now we turn to the results of recent surveys. More than 75 percent of designers of printed circuit boards have already crossed the age of 45 years, and half of them plan to retire in the next 10 years. What does this mean for the industry?

- The designers of the boards experienced three economic crises and are not inclined to share their experience with young people - otherwise they may be dismissed due to staff reductions earlier than they thought.

- Universities and industry cannot find a common language between themselves, and electronics students are still not taught to work with printed circuit boards.

- There is no effective retraining program for the specialty "designer of printed circuit boards."

- In the near future, the industry will not give up printed circuit boards - they have no alternative yet.

- The concept of mechatronic design is gaining popularity, and those who choose to follow it need to understand the advanced methods of designing and manufacturing boards.

In fact, a vacuum has arisen in the electronics industry. Circuit engineers do not plan to design boards - they are more interested in the development of circuit diagrams and writing firmware.

But in reality, boards are just as much a concern for hardware designers. Here the electrical and mechanical components are closed, and what we call mechatronics is formed.

The development of schematic diagrams with power, analog and digital components is still under the jurisdiction of circuit engineers, but we will not exclude that in the future universities will begin to train specialists in mechatronics.

Designers of electronic devices may well take over the baton from the designers of printed circuit boards, and here's why:

Libraries. In the design of boards, one of the main factors is the consideration of the contour of the element. It is also necessary to take into account the location of the findings in order to correctly dissolve the tracks and take into account all the necessary tolerances.

Such nuances are unknown to the circuit design engineer, and the designers of electronic products are very well aware of them. In addition, we should not forget about the height of each particular element, which is important for their proper placement on the board.

Form of payment. The marketing services are becoming more and more actively involved in the process of assembling boards - after all, they have the decisive voice in determining the shape of products, and designers have to take this into account.

In the past, industry and consumers were completely satisfied with rectangular-shaped printed circuit boards that echoed the shape of the product cases. More precisely, the dimensions of the cases were adjusted to the boards that were placed inside. But with the development of design systems, the restrictions have disappeared, and the forms can be arbitrary. Now, on the contrary, the boards are designed to fit into the housing designed by the designers.

Placement of items. Here the design and marketing component is gaining more and more weight. The board, together with the components, is transferred from the design to the circuit design system and back to achieve maximum ergonomics from the product. It should be convenient for the user to press the buttons, set the switch positions, connect the cables and observe the displays and LEDs. Here again we can talk about mechatronics, since in real time there is a parallel development of electronic and mechanical parts. This allows for the correct placement of the board and the components on it, so that conflicts do not occur between them and the body of the product.

Monitoring compliance with the rules. The rules determine, in particular, the gaps between the tracks, the distances between the elements, the width of the tracks, the diameters of the holes and the dimensions of the contact pads. Some of these parameters reflect electrical requirements (primarily in power and high-frequency devices); others proceed from the manufacturability of production. The designer must know the theory of tolerances and be able to apply it in practice.

Layout One of the most serious tasks of the design of printed circuit boards is the routing of tracks, which requires engineers to have experience and qualifications. When teaching this process, the trial and error method is often practiced, so it is difficult to say which engineers will succeed in this. CAD developers understand the problem and try to include as many features as possible in their systems that automate the process. However, users of such CAD systems must have proper experience to work effectively.

Heat dissipation. The problems of heat removal are familiar to everyone, especially the developers of devices for difficult climatic conditions, power and high-frequency devices. Manufacturers of electronic and mechanical CAD systems have responded to this by adding analysis capabilities to their systems. However, the users themselves should be aware of the processes of heat transfer, and universities should attend to teaching the engineers of the relevant disciplines.

findings

We tried to show that the design of printed circuit boards - this is including the responsibility of designers of electronic devices. There are exceptions, and circuit design engineers are involved in the development of high-complexity boards, but in the general case, the task is quite accessible to designers with basic skills in working with CAD electronics.

In addition, it becomes clear that printed circuit boards are mechatronics, and they need to be designed while developing electrical and mechanical components. And in the future we are waiting for such revolutionary technologies as 3D printing, conductive pastes and embedded components. This means that the ways of production and the requirements for the qualifications of engineers will change. And circuitry, and designers will have to actively interact in the process of developing boards and product layout.

Source: https://habr.com/ru/post/437850/