Anisoprint Composer: 3D printing of high strength

Hello! Today you will learn about the advantages and intricacies of working with composite materials, including in 3D printing .

Why ordinary carbon-filled plastics do not give the printed product the properties of carbon? How should the fibers be placed in the material for the greatest strength of the print? What is the novelty of the “Anisoprint” approach to printing with composites and why should you pay attention to it?

The presented material is a lecture by Fyodor Antonov, CEO of Anisoprint , with whom he spoke at the Top 3D Expo.

Video

Performance

What are we talking about

Hello! My name is Fedor, I really like to talk about composites and tell you what composites are used for, what is their advantage; and I’ll tell you a little about where 3D printing is and how it can be combined together.

3D printing, as everyone knows, is related to additive technologies. Manufacturing techniques of composites, which appeared long before 3D printing, were also additive from the very beginning. There are many such technologies. But what we are doing now is a novelty both for the production of composites and for 3D printing, that is, for the additive field in general.

Comparison with metals

I will begin just with a short story about composites, in particular - about carbon fiber, carbon colloquially, which is also called the king of composites. What are its advantages in comparison with metals. For example, you can take some aviation aluminum alloy and look at its characteristics.

It has a density, we will also be interested, for example, temporary resistance or strength.

There is a unidirectional carbon fiber, which is almost two times lighter and five times stronger than aluminum. Thus, it turns out that the specific strength of a unidirectional carbon fiber, as compared with aluminum, is 10 times higher.

If we compare with any steel, even the steepest, the difference will be even greater - because the steel is very heavy. Therefore, all at one time fell in love with carbon fiber and began to make of it highly loaded critical structures - at the beginning in rockets, then in airplanes, now in cars and in a number of consumer goods this unique material is used.

Special features

CFRP is a composite, one of the main features of which is that all these unique properties, all its strength along the reinforcement, along the fibers. In transverse directions, the properties are two orders of magnitude lower.

How carbon engineers “fixed”

For some reason, people decided that the vector nature of carbon fiber is a big drawback, they began to think how to get rid of it. Layers of unidirectional CFRP were laid at each other from different angles to get the so-called quasi-isotropic laminate, which engineers working in this field like to call “black aluminum”.

As we see from the name, by its properties it is like sheet aluminum, it is used in approximately the same structures: aircraft fuselage, wing, rocket body. After the properties of carbon fiber “smeared” in different directions, its strength was about 10 times less. That is - close to the usual aluminum.

And right away we lost all the remarkable advantages that unidirectional CFRP had, but at the same time we got a lot of problems associated with the technology, with impact strength, features of destruction, with connections of such nodes among themselves. There is a whole range of complex problems. Therefore, in the last generation of civil aircraft there were from 50 to 60 percent of composites, and in the next generation, as industry experts say, there will be at least two times less of them. Therefore, the “Dreamliner” program turned out to be absolutely a failure for Boeing. All the hopes that were placed on composites in aviation were not justified precisely because of attempts to make the carbon fiber “omnidirectional”.

Another approach

And there is another approach. It differs from “black aluminum”. From composites it is very effective to make so-called mesh structures, such as the “Shukhov Tower”. Here, above, the payload adapter of the Proton-M rocket is depicted, which is made of carbon fiber, but not of “black aluminum”, but in the form of a mesh structure with edges of a certain direction and a certain density. The part weighs about 50 kilograms and can withstand a load of 200 tons. A similar detail, made under the same needs, made from a CFRP sandwich, weighs 30 percent more and withstands less stress. With aluminum is still worse.

In this design, the composite works only along the fibers. It does not have the ability to work across, so all its anisotropic properties are used as it should.

Fiber steering

There is another interesting direction, in addition to mesh structures, called “Fiber steering”. This is when we lay the fibers not at fixed angles in a straight line, but along curved paths, so that the directions of the fibers at each point correspond to the directions of the main stress vectors in the part.

This is an aircraft fuselage panel with an inspection opening. It was made by the method of automated calculations. Now, some people call it 3D printing, although this technology is several decades old and it has been actively used for the manufacture of parts from composites for a long time. Here on such curvilinear trajectories.

Comparative tests of such parts and “black aluminum” were conducted. This panel, fayber-stiringovaya, with the same weight and nature of the loads, can withstand a greater compressive load by 30 percent. In this case, it is clear that a completely different character of destruction. This panel works much more efficiently.

Tasks

One of our main ideas was to enable design engineers to manufacture, manufacture and design truly effective composite structures. To move away from “black aluminum” and to make the anisotropy of material from a disadvantage, as many believed, became the main advantage of this material. That is, we say that isotopic material is good, because knowing how the part works, knowing the loading conditions, design cases, knowing the internal forces and stress, we can focus the material properties at each point exactly in the direction in which it is needed. Thus, we get a whole additional space for optimization. We can optimize not only the shape of the parts, but also their internal structure.

Why 3D printing

Unfortunately, traditional automated manufacturing techniques for parts made of composites do not allow laying fibers at any point arbitrarily at every point. When we first started to deal with this topic, which grew into the product that we are today, including at this exhibition, it grew out of the idea that we want to make composites, in which you can arbitrarily control the direction of anisotropy and the degree of anisotropy in every point of the material. Old technology did not allow this. Then we decided to look - what can bring us closer to this goal. And here 3D printing technologies turned out to be very useful.

Composite, but not that

What in general in the world of 3D printing is done with composites. The simplest thing everyone knows: when we say that we print with carbon fiber, everyone says that they all print with carbon fiber. No, everyone does not print like this carbon fiber. Usually it is plastic filled with chopped fibers, in fact, it is an ordinary plastic with a filler, an isotropic material in which we do not control any direction of these fibers.

This, of course, is also an interesting thing, but there are no properties here that even come close to the properties of real composites. The material turns out a little more, well - two or three times, more rigid than ordinary plastic. Sometimes it can be a little stronger. It behaves much better when shrinking. These technologies, for example, are successfully used for printing large-sized parts - there are several meters there. But nothing new, precisely from the point of view of design and from the point of view of technology as a whole, this approach does not. This is the usual FDM, or, as in this case, SLS, when we add finely chopped fiber to the polyamide powder.

If we talk about the properties, yes - at OXFAB, this is an SLS machine for printing composites, the claimed strength of prints is 110 megapascals, and for ordinary polyamide, which is not filled, 40-50. Yes, it is better than ordinary plastic, but not an order of magnitude.

In addition to chopped fibers, there is an interesting option with long fibers, for example - lamination technology. I know three or four things, probably, but then I will say one thing. I do not know, to be honest, what is the fate of this project. A couple of years ago, EnvisionTEC showed it as a prototype on FormNext in my opinion. This is not entirely additive technology.

Sheets are taken from carbon fabric pre-impregnated with thermoplastic, so-called “prepregs”. In one zone, this sheet is cut along the contour of the layer, possibly with ultrasound, in the other zone it is then rolled up, laminated, and thus a layer is formed. This is pure black aluminum, only made on a special machine. That is, it is such a quasi-isotropic material, in which there are all the drawbacks of “black aluminum”, such as fiber breakage and, as a result, stress concentration, and edge effects, which lead to holes and joints becoming very weak points. .

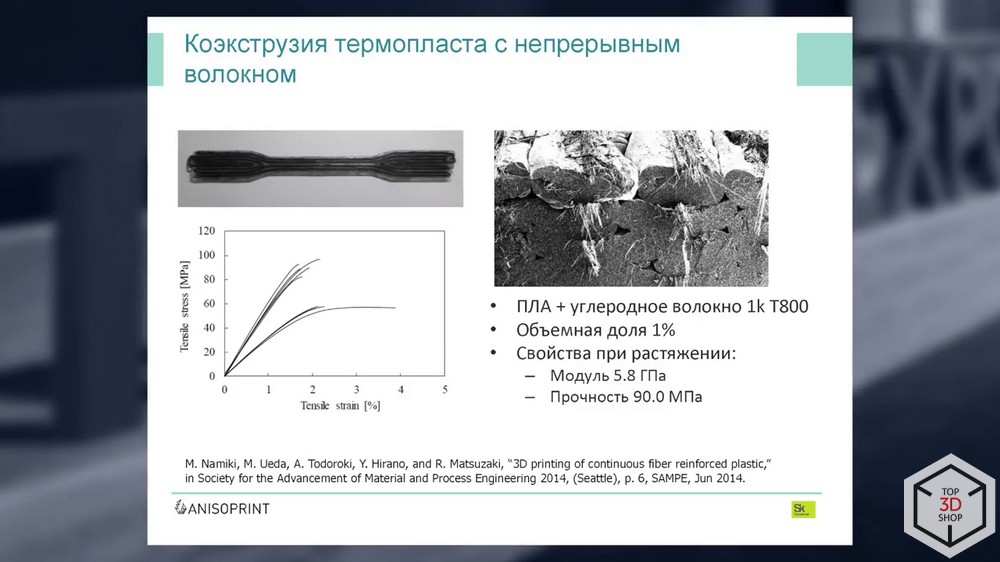

The next step, a little closer to what we started to do, is the extrusion of a continuous fiber thermoplastic. In essence, this is FDM technology, only during the printing process, the reinforcing fiber is continuously added to the nozzle. Quite a lot of research groups around the world are doing this.

The problem here is that the construction fibers are not monofilament, they consist of hundreds or thousands of micron filaments, and if we just add this fiber to the melt of viscous plastic, it does not get inside, does not impregnate the fiber and the composite is not formed. Inside it turns out one big time. A composite does not work, because the composition must have a reinforcing fiber and a binder that connects all the components together, forcing them to work together. In this case, this does not happen. Therefore, although the tensile strength can be quite large, there are no special characteristics for compression in such materials. If you look at microscopy, there are a lot of pores between the fibers inside.

The second approach, a little more successful, I call it “prepreg layout” - this is when we take the same fiber, such as carbon or glass, and beforehand, with a special installation, soak it with a viscous plastic under high pressure, or soak it in a solution and then evaporate and stretch through the spinneret.

That is, we are trying to put this viscous plastic in the fiber beforehand, on a special machine. At the exit, we obtain a soaked thread, which is traditionally called “prepregs” in the composite industry. That is - a semi-finished product for the manufacture of composite. And then we heat this “prepreg” through the nozzle and form the part by extrusion or laying.

The most famous example in the world of 3D printing, when people print in continuous fiber, is the American company Markforged. They have been selling these systems for quite some time. This is also a prepreg calculation. They also have carbon fiber pre-impregnated with nylon and a nozzle in which it is heated and laid out. And there is an additional plastic nozzle, just plastic for printing. Markforged prints have pretty good features. Durability is already over 700 megapascals. There is a choice of types of reinforcing fibers. But, as we see by the number of pores, and there are a lot of articles where the microstructure of these materials is investigated, the number of pores is very large. Either because the impregnation is bad, or because it is nylon and it draws water and boils when printed.

Anisoprint technology

We pre-impregnate the fiber, but not with thermoplastic, but with thermo-plastic, which allows us to provide better, cheaper, more reliable impregnation of this fiber. And we already call such a process co-extrusion. Since such a fiber cannot be melted, we add plastic to it separately during the printing process. And the output is a two-matrix composite, in which inside the fiber we have not melted thermoset plastics, which provides impregnation of the fiber, and between the fibers we have a thermoplastic that binds them together.

In our case, this plastic can be anything. If you need a non-flammable plastic, or colored, or plastic with resistance to certain chemical or thermal effects or the environment - you can choose the plastic that suits you. Because all the main surface properties of the material are determined precisely by the binder - the matrix. And we can, due to the fact that fiber and plastic are fed separately, at each point locally change the volume fraction of fiber and plastic. We can deliver less plastic - then the volume fraction of the fiber increases, we can supply more plastic - then it decreases. In this way, we can control the degree of anisotropy and, more importantly, print mesh designs with fiber intersections within a single layer. That is, we can stack the reinforcing fibers on top of each other, at any angles we need, within each layer individually. At the same time, the thickness of the layer at the intersection does not grow in our country, only the volume fraction of fibers in this very place changes.

There are a lot of advantages. Such an advertising self-confident slide. 20 times stronger than plastic, twice as strong as aluminum, much cheaper than metal printing. All that I have said about optimization, automation, cleanliness - all this is also characteristic of this technology, however, as well as of some competing technologies.

Another advertising slide, which I have long been showing at all conferences. If we take the cost of equipment along the abscissa, according to a logarithmic scale, and along the ordinate, the specific strength of the material, that is, the strength attributed to the specific weight, then all metals printed using the SLM technology turn out to be at the bottom of the graph, and the best of them is titanium.

Equipment and software

Anisoprint composer

- Dimensions, mm: 600x400x375;

- Weight, kg: 25;

- Software: Anisoprint Aura (FFF + CFC), Cura, Slic3r (FFF only);

- Material: PETG; Carbon Fiber; PLA; ABS; Nylon; PC, etc .;

- Heated platform: heated glass;

- Working chamber: 279х210х147 mm;

- The temperature of the printing table: 20-120 ° C;

- Extruder temperature: 250 C;

- Printing technology: FDM; CFC;

- Layer thickness: from 60 microns;

- Thread diameter: 1.75;

- Interfaces: SD, USB;

- Number of print heads: 1;

- Price, rub: 690 000 (approximate, exact price learn on the site ).

We have all this patented, of course, all this technology.

Anisoprint aura

For these printers, we created our own specialized software called “Anisoprint Aura” - this is a slicer, you can manage reinforcement, set plastic perimeter and plastic filling, composite perimeters, composite filling, supports, in general - all the functionality of a regular slicer, plus the functionality for work with the reinforcing fiber.

Here, a closed case, a heated table, the frame is made of milled aluminum plates with rail guides along the z axis. CoreXY scheme.

Prototypes and plans

Anisoprint prom

Our main goal is industrial equipment for 3D printing of composites. We already have a number of prototypes that stand with our partners. Partners successfully work on these prototypes. We have already shown at the metalworking exhibition a prototype of our first industrial printer Anisoprint ProM-PT, which we will show once again in working condition on FormNext, and plan sales from the second half of 2020. The difference is that it has a six-coordinate industrial manipulator instead of a portal scheme, which allows laying the fibers not only in the plane, but also at any angles.

That is, on an ordinary flat pattern, I can print these details, where I have reinforcement inside the plane. As soon as I need to get out of the plane and, let's say, reinforce in the other direction, then I need to have additional degrees of freedom, for which this six-coordinate machine is being developed by us. Apart from the fact that there is an industrial robot, there is still all industrial electronics - no step makers, servo drives, a BOSCH controller, which is integrated into the robot controller. All this ensures reliability, repeatability, redundancy, meets industrial requirements.

Our next planned industrial product is a three-coordinate printer for printing with high-temperature plastics such as PEEK and PSU.

Well, the very top is an additive machine for manufacturing high-temperature parts in six coordinates, but this is our most long-term goal. This technology is intended for the manufacture of parts of complex shape made of composites optimized for a given load and for specified working conditions.

About competitors

In principle, such parts are not made of composites by any means. That is, if you want to make such a part from a composite, our way is the only one existing. Other manufacturing techniques of products from composites are intended mainly for large-sized sheet metal parts or profiles, beams, and here it is possible to manufacture parts of complex shape. But we also want to fight with metals, to win market share from them. Parts of this type, such as brackets, connection elements, enclosures — all loaded parts of complex shape are made by milling or casting. We can ease them at times.

Well, since I’m holding this part in my hands, this is an element of the legs of the aircraft seat, the original aluminum part weighs 1 kilogram and is designed for a load of one and a half tons. Here it is - an optimized composite part made by us, designed for the same loads. It weighs 275 grams - almost four times lighter. And at the cost of this item will also be cheaper than milled aluminum, made on multi-axis milling machine.

Another comparison illustrates the difference. It is that we can ensure reliable impregnation and the absence of pores in the material, which is very important for certification, for critical parts, for critical structures. We call this technology “anisprinting” - it’s not just 3D printing, it’s two different things.

This is a rather important point: there is such a very fashionable trend in the design of engineering products - called topological optimization. I will not go into details. In most cases, the details that are obtained as a result of this generative design have the form of mesh structures. Naturally, we do not have questions in which direction in the rib to lay the fibers. An edge is a one-dimensional structure that works either in tension, or in compression, or in bending. It will not work for transverse separation, because this measurement is very small. It will not work on interlayer shear, only in bending. Thus, the properties in the transverse direction in the edge, the properties of the material across the edge, they are redundant. That is, it does not make sense to make these edges from an isotropic material, because the transverse properties of the material are not needed there. They are not needed the same as they are needed along the edge. Therefore, it is necessary to use isotropic materials. This is the best example that proves the advantages of anisotropic materials over isotropic materials.

Examples and dreams

A few examples of what we did, and a few words about an even more distant future, as we see it.

This airplane in the corner, this is an Airbus concept - called the Airbus 2050, here an artist or designer, probably not an engineer, depicted a fuselage on the plane. I do not know what he put into this picture, but it is this type of product that we want to learn to do in the future. There are edges here - optimal use of composites. This design will work most efficiently. Besides the fact that it is reinforcement along arbitrary anisotropy control paths, during the production process of this type of parts, you can add various functional fibers, functional elements, inserts, electronics. You can make adaptive materials, add any healing agents. Something like this, in our opinion, should look like the future of production in the long term. And, of course, composites should be the basic material.

You can buy a 3D printer for printing with Anisoprint Composer composites or pre-order an industrial model in Top 3D Shop.

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/439062/