Cheaper price of small series of electronics in Russia. Case Internet radio WOLNA

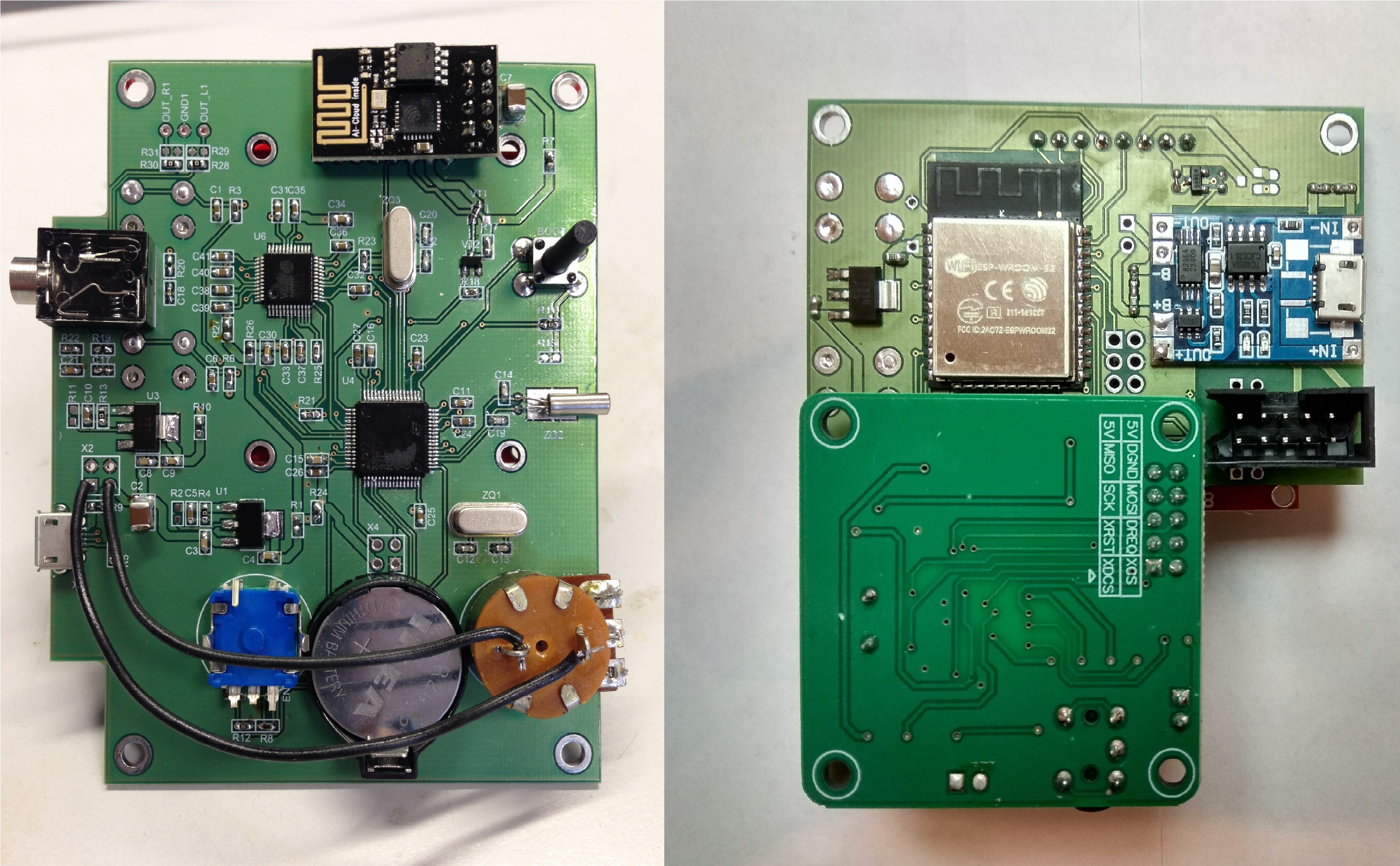

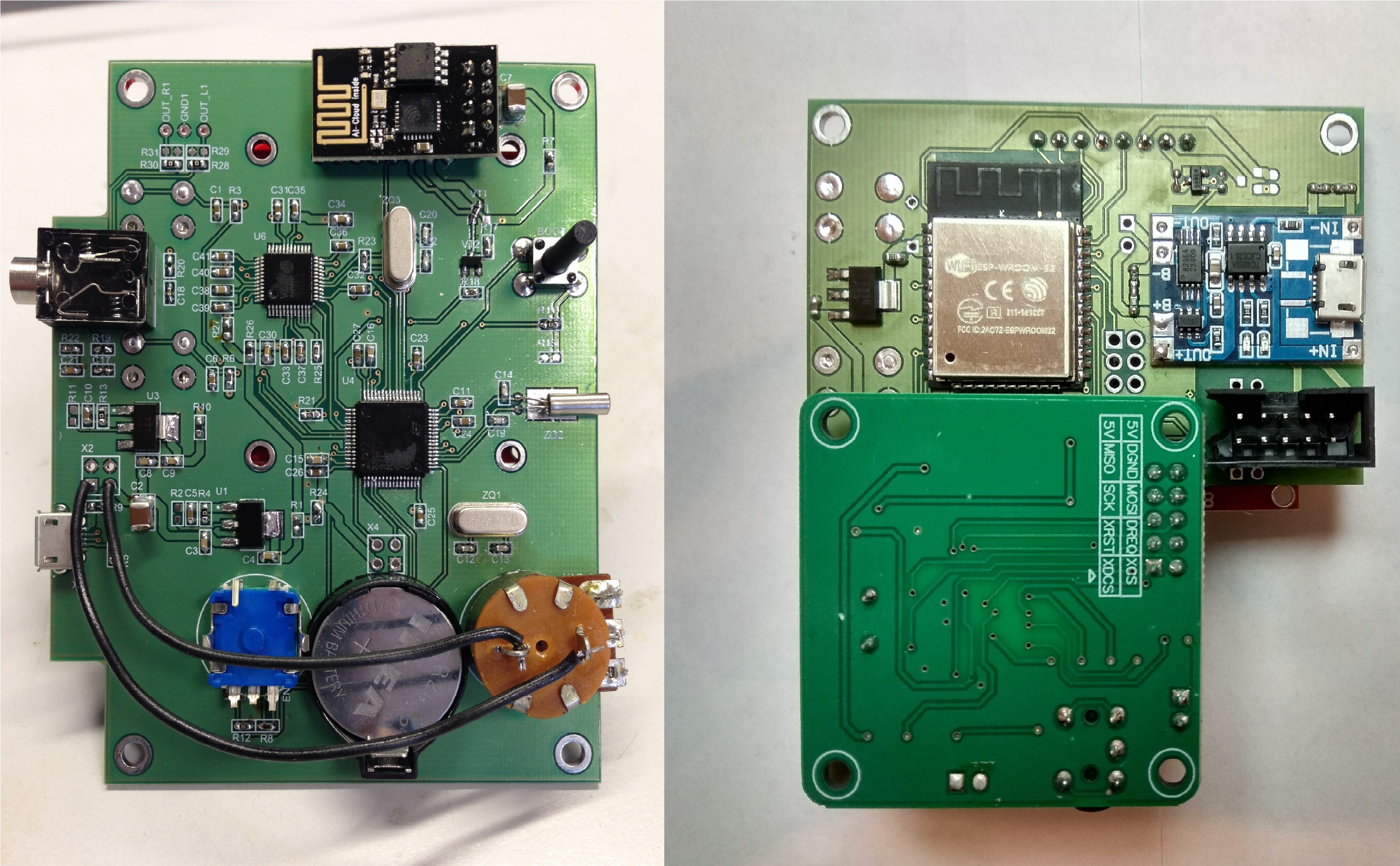

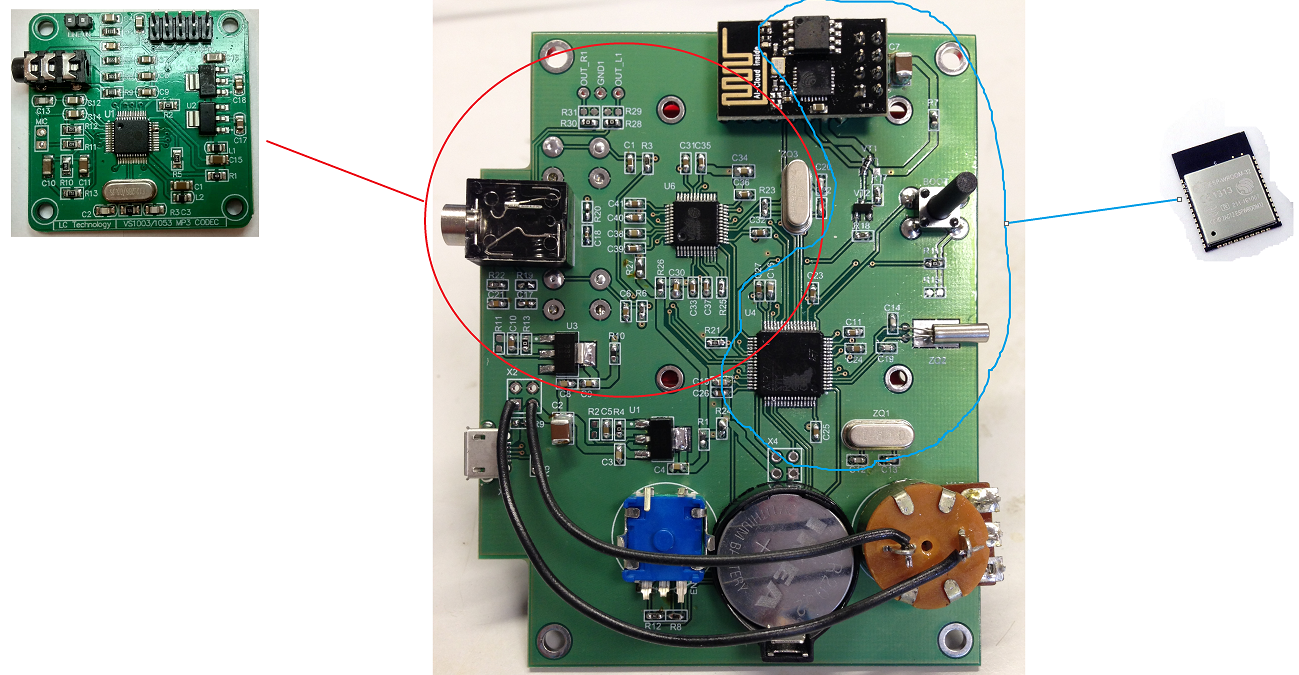

On the picture below is a photo of two versions of the WOLNA-1 Internet radio board. On the left, before I realized how to optimize the cost, and on the right after. For comparison: 120 soldering points against 300 , 20 components against 80 , 14 points in the BOM instead of 31 . And at the same time, the functionality became wider, a lithium battery power controller appeared. Who cares how it happened and how much it helped save, welcome under cat. Also, this material will be useful to inexperienced development customers who contact freelancers.

I'll start from afar. When I was working as an electronics developer, in a large industrial holding company, I heard from my superiors the phrase: “If it works, no matter how much it costs, we will still sell with a wrap of 1000%.” This, of course, was about the state order. And we put the FPGA Xlinx Zynq (~ $ 300) on the boards, which were produced in dozens, and then these boards could never see the light at all. The system worked in such a way that the developer doesn’t see the price of the components at all, the BOM goes to the purchasing department, and there the buyer doesn’t look at the list. And it turns into a habit, and migrates to freelancing and own projects, it happened here.

Of course, this is a colossal technical school, when you can use any state-of-the-art hardware in design, there were no inaccessible technologies for me, accessibility was limited only by my brains, which could not master everything. But it is to some extent discouraging. And if you are a customer, here is the first checklist item for you: see where the engineer works for whom you order the board design. If you are an engineer,you can start to be offended, remember, I am sure that you did not always live so fat :-)

There is another extreme. Also tell an example from my experience. I once had a contract order for the development of a piece of iron that measures distance with the ultrasonic method. We talked with customers on Skype, I voiced the price, time, and at that point he was gone for 4 months. Then he appeared and asked to complete the project that was left unfinished by someone. I began to watch the archive with materials from the previous artist: he went to the bazaar, bought a broken parking sensor, soldered Atmega to him with snot (there was no arduin then), put it all in a shoebox, which I measured in parrots, sketched a diagram in Sprint Layout and stalled further. It turned out that he was a literate amateur, but he didn’t even have experience with ordering printed circuit boards in production. He simply did not know the requirements of serial production of boards. In general, further the prototype in the form of a bundle of wires from recycled materials did not go. So the second point of the checklist for the customer: see the portfolio artist. There must be at least one working piece of hardware.

All that happens next is between these two extremes, and at the same time it requires an understanding of the economics of the emerging project, circuit design, and knowledge of the element base offered on the market. Some of the proposed solutions are not popular among the audience with caps, mainly from the first example. They would prefer that the project died, or was not born, than it will be made not according to the canons or God forbid on Arduin. Once again, most likely this is the opinion of people who have never paid for what they are doing. And yes, this is all true for small series of 100 ± 100 pieces per month in Russia. But 4 out of 5 projects (my statistics) will not pass this line, due to the fact that their economy does not converge.

So, what signs should have an economical project:

1. W. Unification

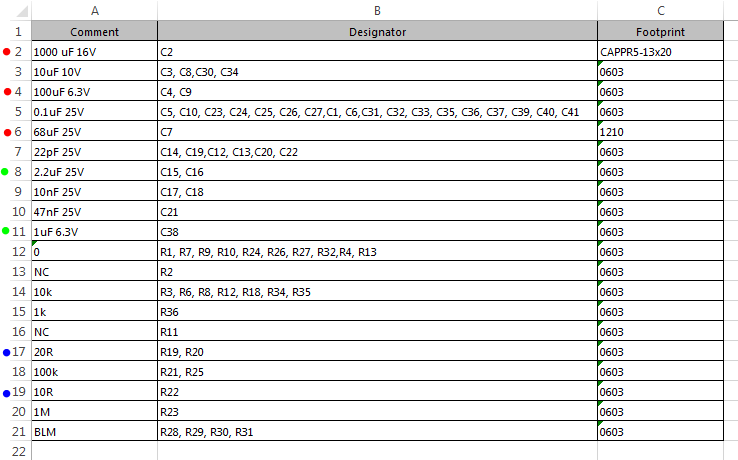

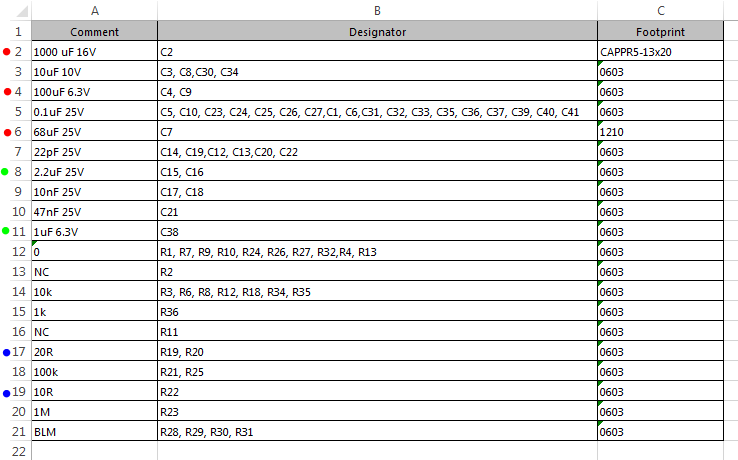

Look at the BOM list of passive components of the first board - this is the first version of the Wave-1 radio. This sheet, by the way, is also not so bad in this sense, but there is still where to work. Points, I noted the components of different denominations, which can most likely be replaced by one medium.

In digital electronics, rarely does the difference between resistors and capacitors matter more than an order of magnitude. Therefore, in my BOM sheets there are rarely resistor values other than 1k, 10k, 100k, 1M, and capacitors 0.01uF, 0.1uF, 1uF, 10uF, 470uF. if intermediate values are needed, sometimes you can put two in parallel or in series.

Why it is so important, and why I prefer not to save on the number of passive components, but rather to their nomenclature. First, they are sold by coils of 1000pcs, and the price of one chip resistor or capacitor is literally a penny. But what really eats money in direct form, and in the form of indirect costs, is the purchase of a larger number of nomenclature. That is, I had to take not 1 coil of 1000 resistors but two. Not one capacitor coil, but three. And God bless them, but then the problem of monitoring the availability of all this zoo in stock comes up. And here I’m just urging you to believe in experience, you’ll surely miss the moment when something is over, and all production will rise due to some one element.

So, the benefit of unification is as huge as it is not obvious. The fewer items on the parts list, the less chance there is to notice how something is over. Calculate how much he eats the day of idle space, installers, and shipment delays, and look at your BOM again :-)

2. W. Enlargement

This is generally otkrytie, revelation, and at the same time the main complaint to me from the capsists. The essence of the enlargement is to take as many ready-made blocks as possible.

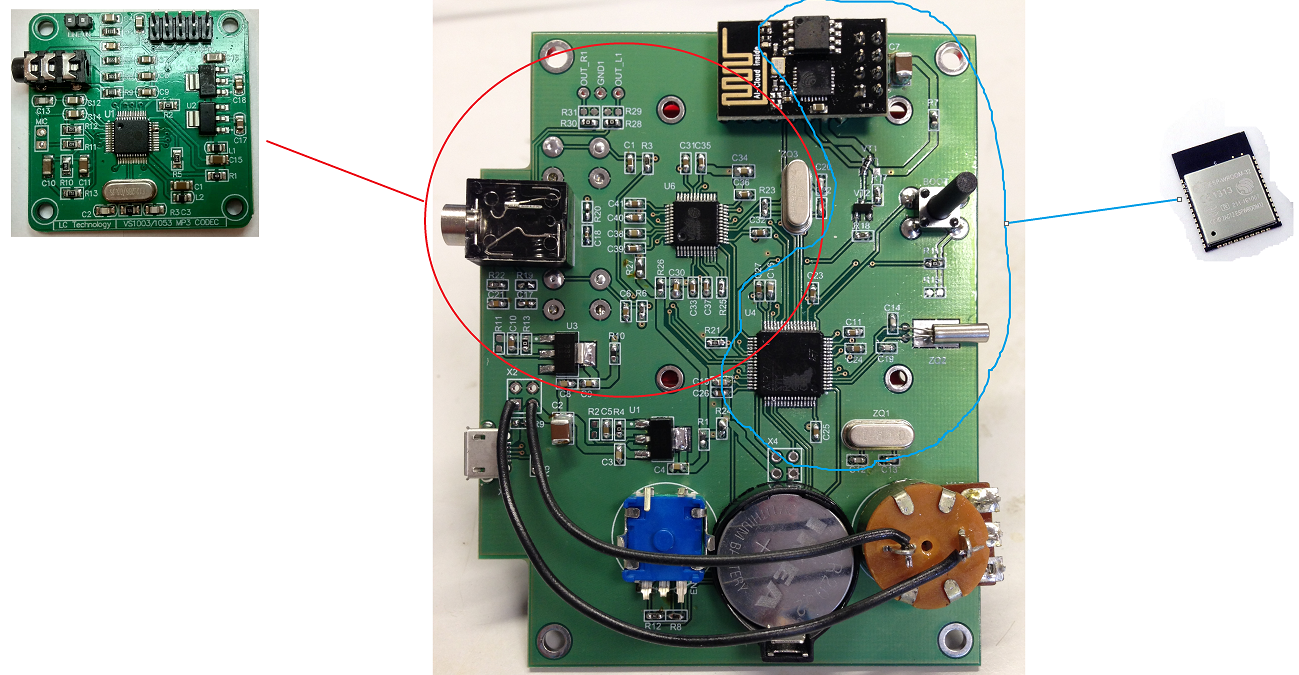

For example, the module of the codec vs1053 (on the left in the picture below) with the whole body kit costs me when ordering wholesale in 340p. All you need is to solder 10 pins PLD2.54. A separate chip in the QFP48 package costs 270r, but it still needs to be under 10 positions of a passive body kit. This is ~ 100 soldering points at 2p = 200r, as well as the increased probability of rejection due to the QFP48 case. Add this to the previous point, and decide that it is easier to organize the purchase and monitoring of 1 large component cheap, or 10 small ones expensive?

Before I calculate how much money the enlargement of the project of the WOLNA Internet radio has saved, I will make a small lyrical digression. One day, the person to whom I refused to make a discount promised to inform the "federal authorities" that in fact the "domestic" Internet radio was not actually domestic, due to the fact that it was made from foreign components. And I meet such comments among the public who know about the existence of arduino: “all this is arduinization, and people have no brain of their own”. You can call this phenomenon as you please, even if it is “arduinization”, I call it the global distribution of labor: the Chinese do a cool and cheap solder, and I order from them not my own board design, but choose from ready-made ones. And you certainly don’t have to go about the general opinion, and refuse this cool life hacking, because the piece of iron looks like an arduino designer. And it may seem that this provides greater margins and profits to greedy businessmen like me, but in fact, this is not about profit, but the viability of the project in general.

So, let's compare 2 versions of the same board by several parameters:

2.1. The number of soldering points and the cost of assembly:

- Version 1 on loose elements - 300 soldering points 2 rubles each ~ 600 rubles.

- Version 2 on enlarged modules - 120 soldering points, 2 rubles each ~ 240 rubles.

2.2. Number of positions in BOM:

- Version 1 on loose elements - 31 position

- Version 2 on integrated modules - 14 positions

Here the difference in money should be considered depending on how the process is organized, the level of wages and other things. But it is tens percent of the cost price. I will simply list which areas besides the assembly itself are affected by the number of positions in the specification sheet:

Regarding the last point I want to stay a little more. It turns out that if you are a manufacturer, then such a thing is obligatory for you - “the rate of consumption of a product”, where you yourself prescribe everything of what it is that you sell. And all this you should have at the time of shipment. That is, yes, even the formal absence of 1 resistor on the balance sheet of the enterprise will not allow you to ship the goods to the buyer. Yes, bookkeepers know how to work with this, make backdating purchases, and so on. But think, you need it, because they take money for it, and all the time? And most importantly, does the developer with whom you work think about this? Do you consider this when developing if you are an engineer?

So how much is it in the money? It depends on how everything is organized with you, but in my particular case it is at least:

And all this is not just greed and loot, but the vitality of an idea, and the opportunity to give the world what you love at the lowest price.

In the end, you can watch the news story about us, and see how the Russian micro electronics manufacturer WOLNA works.

PS: And yes, even though I’m almost no longer doing custom development, if you have interesting projects, you can write to me and discuss. But better just look at the cool internet radio WOLNA :)

I'll start from afar. When I was working as an electronics developer, in a large industrial holding company, I heard from my superiors the phrase: “If it works, no matter how much it costs, we will still sell with a wrap of 1000%.” This, of course, was about the state order. And we put the FPGA Xlinx Zynq (~ $ 300) on the boards, which were produced in dozens, and then these boards could never see the light at all. The system worked in such a way that the developer doesn’t see the price of the components at all, the BOM goes to the purchasing department, and there the buyer doesn’t look at the list. And it turns into a habit, and migrates to freelancing and own projects, it happened here.

Of course, this is a colossal technical school, when you can use any state-of-the-art hardware in design, there were no inaccessible technologies for me, accessibility was limited only by my brains, which could not master everything. But it is to some extent discouraging. And if you are a customer, here is the first checklist item for you: see where the engineer works for whom you order the board design. If you are an engineer,

There is another extreme. Also tell an example from my experience. I once had a contract order for the development of a piece of iron that measures distance with the ultrasonic method. We talked with customers on Skype, I voiced the price, time, and at that point he was gone for 4 months. Then he appeared and asked to complete the project that was left unfinished by someone. I began to watch the archive with materials from the previous artist: he went to the bazaar, bought a broken parking sensor, soldered Atmega to him with snot (there was no arduin then), put it all in a shoebox, which I measured in parrots, sketched a diagram in Sprint Layout and stalled further. It turned out that he was a literate amateur, but he didn’t even have experience with ordering printed circuit boards in production. He simply did not know the requirements of serial production of boards. In general, further the prototype in the form of a bundle of wires from recycled materials did not go. So the second point of the checklist for the customer: see the portfolio artist. There must be at least one working piece of hardware.

All that happens next is between these two extremes, and at the same time it requires an understanding of the economics of the emerging project, circuit design, and knowledge of the element base offered on the market. Some of the proposed solutions are not popular among the audience with caps, mainly from the first example. They would prefer that the project died, or was not born, than it will be made not according to the canons or God forbid on Arduin. Once again, most likely this is the opinion of people who have never paid for what they are doing. And yes, this is all true for small series of 100 ± 100 pieces per month in Russia. But 4 out of 5 projects (my statistics) will not pass this line, due to the fact that their economy does not converge.

So, what signs should have an economical project:

1. W. Unification

Look at the BOM list of passive components of the first board - this is the first version of the Wave-1 radio. This sheet, by the way, is also not so bad in this sense, but there is still where to work. Points, I noted the components of different denominations, which can most likely be replaced by one medium.

In digital electronics, rarely does the difference between resistors and capacitors matter more than an order of magnitude. Therefore, in my BOM sheets there are rarely resistor values other than 1k, 10k, 100k, 1M, and capacitors 0.01uF, 0.1uF, 1uF, 10uF, 470uF. if intermediate values are needed, sometimes you can put two in parallel or in series.

Why it is so important, and why I prefer not to save on the number of passive components, but rather to their nomenclature. First, they are sold by coils of 1000pcs, and the price of one chip resistor or capacitor is literally a penny. But what really eats money in direct form, and in the form of indirect costs, is the purchase of a larger number of nomenclature. That is, I had to take not 1 coil of 1000 resistors but two. Not one capacitor coil, but three. And God bless them, but then the problem of monitoring the availability of all this zoo in stock comes up. And here I’m just urging you to believe in experience, you’ll surely miss the moment when something is over, and all production will rise due to some one element.

So, the benefit of unification is as huge as it is not obvious. The fewer items on the parts list, the less chance there is to notice how something is over. Calculate how much he eats the day of idle space, installers, and shipment delays, and look at your BOM again :-)

2. W. Enlargement

This is generally otkrytie, revelation, and at the same time the main complaint to me from the capsists. The essence of the enlargement is to take as many ready-made blocks as possible.

For example, the module of the codec vs1053 (on the left in the picture below) with the whole body kit costs me when ordering wholesale in 340p. All you need is to solder 10 pins PLD2.54. A separate chip in the QFP48 package costs 270r, but it still needs to be under 10 positions of a passive body kit. This is ~ 100 soldering points at 2p = 200r, as well as the increased probability of rejection due to the QFP48 case. Add this to the previous point, and decide that it is easier to organize the purchase and monitoring of 1 large component cheap, or 10 small ones expensive?

Before I calculate how much money the enlargement of the project of the WOLNA Internet radio has saved, I will make a small lyrical digression. One day, the person to whom I refused to make a discount promised to inform the "federal authorities" that in fact the "domestic" Internet radio was not actually domestic, due to the fact that it was made from foreign components. And I meet such comments among the public who know about the existence of arduino: “all this is arduinization, and people have no brain of their own”. You can call this phenomenon as you please, even if it is “arduinization”, I call it the global distribution of labor: the Chinese do a cool and cheap solder, and I order from them not my own board design, but choose from ready-made ones. And you certainly don’t have to go about the general opinion, and refuse this cool life hacking, because the piece of iron looks like an arduino designer. And it may seem that this provides greater margins and profits to greedy businessmen like me, but in fact, this is not about profit, but the viability of the project in general.

So, let's compare 2 versions of the same board by several parameters:

2.1. The number of soldering points and the cost of assembly:

- Version 1 on loose elements - 300 soldering points 2 rubles each ~ 600 rubles.

- Version 2 on enlarged modules - 120 soldering points, 2 rubles each ~ 240 rubles.

2.2. Number of positions in BOM:

- Version 1 on loose elements - 31 position

- Version 2 on integrated modules - 14 positions

Here the difference in money should be considered depending on how the process is organized, the level of wages and other things. But it is tens percent of the cost price. I will simply list which areas besides the assembly itself are affected by the number of positions in the specification sheet:

- Monitoring of the warehouse (already written 100 times, but I repeat).

- The number of suppliers. The more positions, the less chance of finding everything in one place at a bargain price.

- Preparation of procurement reporting documentation for tax. For each purchase you will have to exchange documents with the supplier, if you are an LLC, or SP in some cases.

- Preparation of reporting documentation on the balance sheet for tax. It turns out that you cannot sell what you did not buy. And if your piece of iron consists of 30 items, then you must report this to the inspection body, and then strictly ensure that the necessary amount of this junk is purchased from you on the balance sheet, otherwise you will not be able to sell the finished product.

Regarding the last point I want to stay a little more. It turns out that if you are a manufacturer, then such a thing is obligatory for you - “the rate of consumption of a product”, where you yourself prescribe everything of what it is that you sell. And all this you should have at the time of shipment. That is, yes, even the formal absence of 1 resistor on the balance sheet of the enterprise will not allow you to ship the goods to the buyer. Yes, bookkeepers know how to work with this, make backdating purchases, and so on. But think, you need it, because they take money for it, and all the time? And most importantly, does the developer with whom you work think about this? Do you consider this when developing if you are an engineer?

So how much is it in the money? It depends on how everything is organized with you, but in my particular case it is at least:

- 20% for accounting (it is outsourced).

- 30% of the cost (less soldering points and less components, less than their price when buying a ready-made module).

- 10% of the wage fund (where the floor rate of the office manager for the maintenance of the processes associated with the purchase, maintenance and documents).

And all this is not just greed and loot, but the vitality of an idea, and the opportunity to give the world what you love at the lowest price.

In the end, you can watch the news story about us, and see how the Russian micro electronics manufacturer WOLNA works.

PS: And yes, even though I’m almost no longer doing custom development, if you have interesting projects, you can write to me and discuss. But better just look at the cool internet radio WOLNA :)

Source: https://habr.com/ru/post/439436/