Experimental production of electronics for the minimum price

Hi, Habr!

I read some previously published articles on how to live a glorious young man, who was faced with the task of soldering 10-50-100 devices from resistors and microchips, and felt sad, because in all of them advice was given if not harmful, then not very useful .

But, for example, the advice to keep the included soldering iron by the handle is useful!

In this regard, I want to tell you how you can easily solve the problem, which is quite typical for a couple of three individual freelance developers, a small electronics development company or an experienced department in a larger company gathered together:

If you can afford - what's on time, what's on money - the services of “Resonit” or “Compala” (cooperating, however, with “Resonit”) in assembling turnkey modules, then the text below is generally not for you. However, in practice, even in fairly large companies, people involved in prototypes often assemble them themselves - because it takes a couple of days instead of a week, because you can always correct something on the go, because you don’t have to run between the bosses and the accounting department. by bills and acts ... The small question simply comes up against money.

Moreover, in our time, the basic equipment that allows you to do such things quickly and fairly cheaply, is available even to an amateur.

I don’t need to tell this to companies, even small ones, but I’ll mention for those who are just starting to seriously engage in electronics.

An important point for understanding is: the ways of acquiring components by amateur radio Vasya, a company of a dozen people and a company of a couple thousand people are three completely different, practically non-intersecting ways.

At the moment when you become an LLC or at least an entrepreneur, you open the doors of offices that do not work with individuals in general or, at best, have another entrance for them, which operates according to different rules. Prices with purely retail companies (even pretending to be wholesale, such as, for example, Chip-and-Dip) can vary by times, sometimes by dozens of times.

As a rule, most of these companies are not very friendly externally, and to work with them, it is desirable to know two or three managers from there, and if you have an online store, register with it and provide information about your legal entity. However, if they feel that you are sane and can come later with a good order, they will be happy to be friends with you.

For example, from those whom we use (below I cite only regularly used suppliers, so I apologize to those from whom we take something, but rarely):

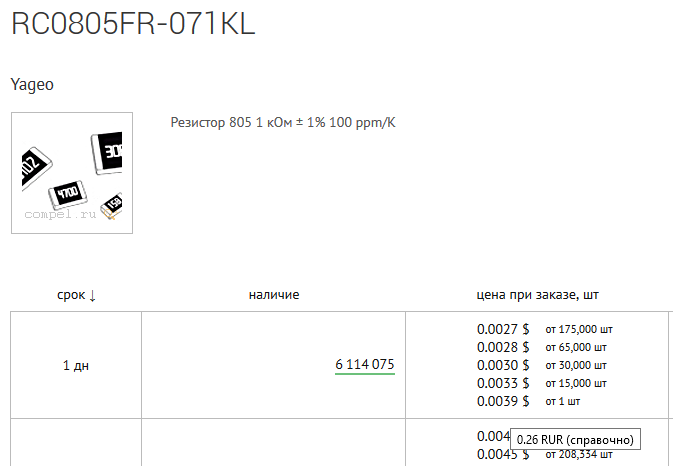

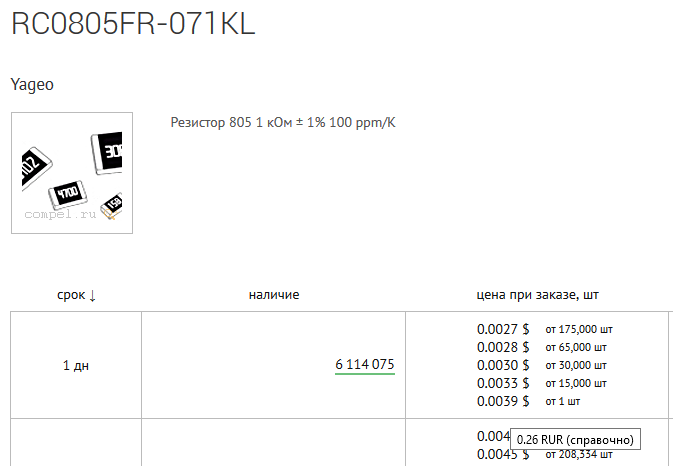

Compal, www.compel.ru is absolutely the largest supplier of components in the CIS countries, has a huge local warehouse and can be supplied from the warehouses of other major Russian distributors and foreign companies. "Terraelectronics", "DKO Electronics" and "Dadzhet" - his daughters to work with individuals in different directions. It has the best ordering system and the best logistics among all Russian suppliers - on sds.compel.ru (available only to registered legal entities) there lives a price and ordering system for local and remote warehouses with a classifier, filters by parameters, datasheets, loading components with a list from a file, automatic selection of analogues and the devil in a mortar. Communication with managers is not required at all, the delivery time from the local warehouse in Moscow is always exactly three days, including the day of ordering and payment, for people with slow bookkeeping there is either a default reservation of the selected product for a week, or a line of credit of several hundred dollars.

In this Compal is very democratic, and any goods from a local warehouse can be purchased in quantities of one piece (even SMD-resistors!).

“Elitan”, www.elitan.ru is an aggregator of suppliers, from Russian (including the same “Compal”) to foreign (Digikey, etc.). It has a poorly maintained directory, so to search you need to know the more or less exact name of the component. Prices and delivery times are available to everyone, the actual delivery time is a little longer, as indicated does not include sending goods from the Elitan office to you.

MT-Systems, www.mt-system.ru is a younger and smaller distributor than Compel, but with much more interesting prices, for example, for the entire line of Simcom communication modules, for some antennas, etc. . Unfortunately, it does not publish prices on the site, but they respond to requests by mail quickly.

“Radiotech-trade”, www.rct.ru - almost any connectors, slots and terminals, Gainta and Sanhe enclosures and other components. They have their own warehouse in Moscow, the website directly indicates the availability on it and prices. Do not like to sell in quantities not multiples of the whole package. Available also through Compal and Elitan with a delivery time of several working days and a price that is not very different from the home one.

“Ecomp”, e-components.ru, formerly known as “Eltech” - there we take NDK quartz resonators (and with good and inexpensive quartz on the Russian market in general is somehow not very good), and sometimes various connectors. The site has a catalog with availability and prices.

“SMP”, www.smd.ru is a unique place where you can buy SMD passive of almost any denomination without registration and SMS, that is, including individuals and including cash, and from either 10 or from 30 pieces and at quite reasonable prices (higher than that of Kompela, but those who are used to Chip-i-dip, the price list of the SMP will make you cry two or three days). Prices are available on site after quick registration.

“Ultran”, www.ultran.ru - here we go for nRF52, when someone again needs a lot of BLE-bicons with pearl buttons, as well as U-blox communication modules. The site has prices and availability, but inaccurate - a party of ten thousand pieces hanging in the “in stock” condition may already be fully reserved for someone else’s project.

And so on and so forth. Although there are a lot of companies in Russia that do not have anything except an office with sales, and are ready to carry everything from outside foreign warehouses to you, but at exorbitant prices, it is not much less than real suppliers of components, as well as adequate aggregators, work with which is available. only legal entities - and which are an order of magnitude more profitable than typical retail stores such as "ChiD", "Volmaster" or "Quartz". However, many of them do not require a dreary correspondence with managers for every sneeze, but have quite developed order systems.

If you have started to engage in electronics for sale and have a legal entity or individual entrepreneur, you should familiarize yourself with these companies.

PS: I will not specifically talk about how to buy in China, as well as how to optimize BoM. It’s better not to do the first in the professional field at all if you don’t know exactly what you are going to, and whether it is possible to change all resistors on the board for three 1-10-100K values, or 0.1-percent Yageo RT0603 is better left as is, even if you have to pay extra - you know better yourself.

Here, to be honest, there is nothing to say, we order everything from Rezonit, from Russian manufacturers they have the best combination of time, price and quality. A two-layer small board in a batch of 10-20 pieces with a production time of 4-5 days will cost you 3-4 thousand rubles per batch.

At the moment, I personally have 177 completed orders there and one in the process. The minimum batch of what we ordered there was 1 piece, the maximum - several thousand pieces.

To estimate the cost of manufacturing, there is a calculator , which is essentially no different from the usual form of ordering boards in your account — well, except for the ability to upload files and send them to the factory.

And here, of course, the most interesting begins - there are boards, components are there, then what?

The main thesis: modern boards are not manually collected with a soldering iron .

Even in pilot production. Even ten pieces. It is simply a chore, long, ineffective and poor quality. Manual soldering violates the main principle of work efficiency - monotony. Manual soldering is a constant, every second tool change in the hands. If it is not your goal to spend too much time, you can’t do that.

On modern boards, the absolute majority of components are SMD, and moreover, when you try minimally decent assembly methods, you will cry every time you have to install a THD component.

SMD components are soldered with a paste - a mixture of flux and micron-sized solder balls (we use Multicore CR36, but this is not necessary).

Paste is applied strictly to the contact pads of the components in one of two ways:

Any options with smearing toothpick, manual pressure from a syringe, etc. Forget immediately - you hang yourself on your very first board.

This part would not be so fun - the stencil piece is quite expensive - if it were not for one wonderful invention of mankind: the Silhouette Curio cutting plotter, designed to cut appliqués for scrapbooks, but also copes well with “ transparencies ” for projectors. The latter are 100 microns thick - do you think this is just a coincidence?

The plotter accepts DXF files as input (in the free version of the software; the paid one adds support for the SVG scrapbooks that are very necessary) and copes with components down to SOIC and 0603 without any problems. Passage 0402 is worse, but still acceptable, and you have to remove any QFN separate legs and make a solid slot.

This, of course, is not a stencil for the production of ten thousand devices. But the ability to make a stencil, which is quite suitable for most simple structures, on equipment for 14 thousand rubles, without wet chemistry and in general any significant waste, as well as for fifteen to twenty minutes of time - is priceless.

After cutting and spreading is the alignment of parts .

Of course, it would be nice to have an automatic balancer, but, firstly, the thing is not quite cheap, and secondly, I will tell you a secret, you will take much more time to set up the aligner for a lot of fifty motherboards than the arrangement itself.

Therefore, the base case is manual placement. The easiest and cheapest option is a vacuum tweezer of the type of this , that is, in fact, a handle with an aquarium compressor. The handle has a replaceable needle at the end and a hole in the side, close the hole with your finger - the needle attracts the parts, release the finger - the air goes through the hole, the part falls off.

Unlike conventional tweezers, this piece allows you to take components of any shape and from any surface, including directly from the bands, and unlike mechanical vacuum tweezers with a button and a rubber bulb inside, does not give a jerk when you release the part. It is worth such a penny tweezers - less than 1,500 rubles from the Chinese, and if desired, you can also make the most natural of an aquarium air compressor. Needles are eventually clogged with solder paste, but without problems, they are bought separately, either in sets of different diameters or in packages of one diameter of 10–20–50–100 pieces.

The usual tweezers will be left to place only the largest components, such as processors in LQFP-cases.

An important point: the XXI century is in the courtyard, nobody already does the layout on a paper printout from CAD .

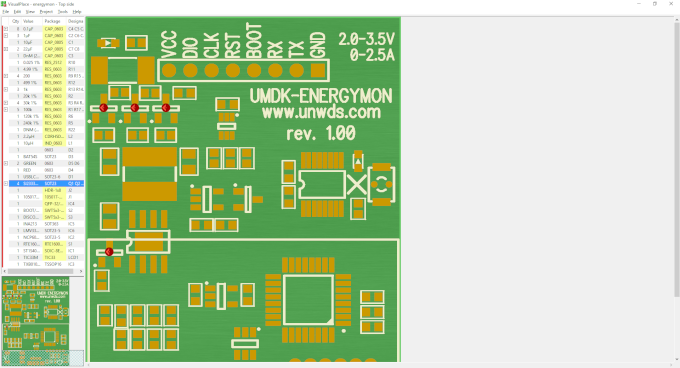

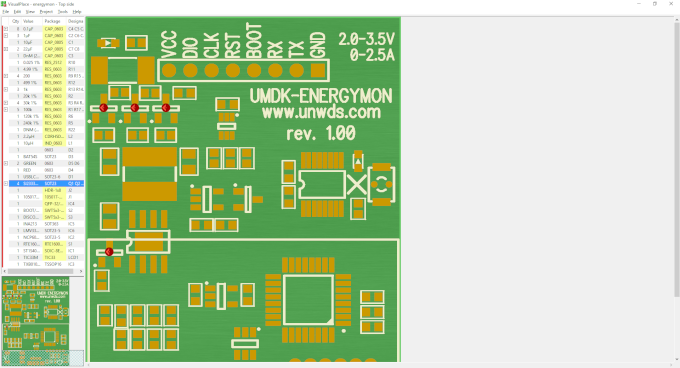

For manual placement, there is a small and extremely useful VisualPlace program that absorbs gerberas, the list of components and their coordinates on the board - and shows you where which component should stand, and also in what orientation:

Moreover, VisualPlace is able to group the components along the value field, so that by picking up the coil of transistors SI2333 and poking the group with them, you will see all the places where they should stand.

The authors wrote the utility explicitly primarily for themselves (and, by the way, they also make a wonderful little Termite ), therefore, on the one hand, it is not overloaded with unnecessary junk and beautiful icons, on the other - there are many rough edges in understanding units of measurement (inches or millimeters), reference points of coordinates in gerberas (I recommend always starting at the bottom left corner of the board), etc. Sometimes, CAD features are superimposed on this — for example, DipTrace on a system with a Russian locale stores numbers with a decimal separator “,”, and VisualPlace waits for “.” Regardless of locale.

However, the CAD exhaust adjustment under VisualPlace takes only a few minutes, and the utility’s utility cannot be overestimated. The utility is officially free for commercial use.

Somewhere around this moment you will feel the beauty of this approach to installation. Compare - soldering iron:

Paste:

Oh yeah. After you have placed the components (it is necessary to put them with a little effort so that they are pressed into the paste), it is time for the stoves .

The stove's task is to heat the paste at a given speed of up to 140-160 degrees (temperature of flux activation and evaporation), then up to 220-230 (melting solder), hold for a short time and cool.

Strictly speaking, it is possible to heat the paste on completely piece products with a hair dryer, but this only works for literally 5-10 copies, and also subjects the components to serious stress due to the large temperature gradients. The stove heats evenly and smoothly.

Again, which is very pleasing - although the Chinese are making quite inexpensive stoves for themselves, you can make a very self-made out of a completely worthless electric oven (I do not recommend this particular model, this is just a link) or aerogrill, adding to them an Arduino temperature controller that can withstand the right one. profile by degrees and by minutes. The cost of such a decision in the knee version will be less than 5 thousand rubles for everything in the amount.

Actually, everything. After baking, it remains on the components with small steps to check the legs for possible sticking (contrary to the statements in numerous manuals - no, the solder paste is not always ideally perfect itself on the leg, if it is slightly larger than necessary, or smeared more strongly than necessary - surface tension is not enough to break the jumper between adjacent legs), all found to remove the usual soldering iron, on chips with long legs and small steps, like LQFP or TSSOP with a step of 0.5 mm, - with braid for soldering.

Well, actually, everything. Products are mounted.

Calculate?

Total - 22 800 rubles for a set of equipment and consumables, which will allow you to mount boards with SMD components several times faster than purely handmade soldering iron. And what's more, it is also of higher quality: if by the results of the soldering iron, it is immediately obvious that the board was assembled by hand (the characteristic nodules on the legs of the components, with a clear excess of solder over what was really needed), then with minimal dexterity even such a primitive set allows you to make products, non-professional point of view is not similar to the serial.

And this is for the amount that many people can afford even as part of a hobby.

And if your wife is also interested in scrapbooks ...

I read some previously published articles on how to live a glorious young man, who was faced with the task of soldering 10-50-100 devices from resistors and microchips, and felt sad, because in all of them advice was given if not harmful, then not very useful .

But, for example, the advice to keep the included soldering iron by the handle is useful!

In this regard, I want to tell you how you can easily solve the problem, which is quite typical for a couple of three individual freelance developers, a small electronics development company or an experienced department in a larger company gathered together:

- regularly you need to do 5-10-50-100 boards with SMD components

- as quickly as possible

- whenever possible cheap

If you can afford - what's on time, what's on money - the services of “Resonit” or “Compala” (cooperating, however, with “Resonit”) in assembling turnkey modules, then the text below is generally not for you. However, in practice, even in fairly large companies, people involved in prototypes often assemble them themselves - because it takes a couple of days instead of a week, because you can always correct something on the go, because you don’t have to run between the bosses and the accounting department. by bills and acts ... The small question simply comes up against money.

Moreover, in our time, the basic equipment that allows you to do such things quickly and fairly cheaply, is available even to an amateur.

Procurement of components

I don’t need to tell this to companies, even small ones, but I’ll mention for those who are just starting to seriously engage in electronics.

An important point for understanding is: the ways of acquiring components by amateur radio Vasya, a company of a dozen people and a company of a couple thousand people are three completely different, practically non-intersecting ways.

At the moment when you become an LLC or at least an entrepreneur, you open the doors of offices that do not work with individuals in general or, at best, have another entrance for them, which operates according to different rules. Prices with purely retail companies (even pretending to be wholesale, such as, for example, Chip-and-Dip) can vary by times, sometimes by dozens of times.

As a rule, most of these companies are not very friendly externally, and to work with them, it is desirable to know two or three managers from there, and if you have an online store, register with it and provide information about your legal entity. However, if they feel that you are sane and can come later with a good order, they will be happy to be friends with you.

For example, from those whom we use (below I cite only regularly used suppliers, so I apologize to those from whom we take something, but rarely):

Compal, www.compel.ru is absolutely the largest supplier of components in the CIS countries, has a huge local warehouse and can be supplied from the warehouses of other major Russian distributors and foreign companies. "Terraelectronics", "DKO Electronics" and "Dadzhet" - his daughters to work with individuals in different directions. It has the best ordering system and the best logistics among all Russian suppliers - on sds.compel.ru (available only to registered legal entities) there lives a price and ordering system for local and remote warehouses with a classifier, filters by parameters, datasheets, loading components with a list from a file, automatic selection of analogues and the devil in a mortar. Communication with managers is not required at all, the delivery time from the local warehouse in Moscow is always exactly three days, including the day of ordering and payment, for people with slow bookkeeping there is either a default reservation of the selected product for a week, or a line of credit of several hundred dollars.

In this Compal is very democratic, and any goods from a local warehouse can be purchased in quantities of one piece (even SMD-resistors!).

“Elitan”, www.elitan.ru is an aggregator of suppliers, from Russian (including the same “Compal”) to foreign (Digikey, etc.). It has a poorly maintained directory, so to search you need to know the more or less exact name of the component. Prices and delivery times are available to everyone, the actual delivery time is a little longer, as indicated does not include sending goods from the Elitan office to you.

MT-Systems, www.mt-system.ru is a younger and smaller distributor than Compel, but with much more interesting prices, for example, for the entire line of Simcom communication modules, for some antennas, etc. . Unfortunately, it does not publish prices on the site, but they respond to requests by mail quickly.

“Radiotech-trade”, www.rct.ru - almost any connectors, slots and terminals, Gainta and Sanhe enclosures and other components. They have their own warehouse in Moscow, the website directly indicates the availability on it and prices. Do not like to sell in quantities not multiples of the whole package. Available also through Compal and Elitan with a delivery time of several working days and a price that is not very different from the home one.

“Ecomp”, e-components.ru, formerly known as “Eltech” - there we take NDK quartz resonators (and with good and inexpensive quartz on the Russian market in general is somehow not very good), and sometimes various connectors. The site has a catalog with availability and prices.

“SMP”, www.smd.ru is a unique place where you can buy SMD passive of almost any denomination without registration and SMS, that is, including individuals and including cash, and from either 10 or from 30 pieces and at quite reasonable prices (higher than that of Kompela, but those who are used to Chip-i-dip, the price list of the SMP will make you cry two or three days). Prices are available on site after quick registration.

“Ultran”, www.ultran.ru - here we go for nRF52, when someone again needs a lot of BLE-bicons with pearl buttons, as well as U-blox communication modules. The site has prices and availability, but inaccurate - a party of ten thousand pieces hanging in the “in stock” condition may already be fully reserved for someone else’s project.

And so on and so forth. Although there are a lot of companies in Russia that do not have anything except an office with sales, and are ready to carry everything from outside foreign warehouses to you, but at exorbitant prices, it is not much less than real suppliers of components, as well as adequate aggregators, work with which is available. only legal entities - and which are an order of magnitude more profitable than typical retail stores such as "ChiD", "Volmaster" or "Quartz". However, many of them do not require a dreary correspondence with managers for every sneeze, but have quite developed order systems.

If you have started to engage in electronics for sale and have a legal entity or individual entrepreneur, you should familiarize yourself with these companies.

PS: I will not specifically talk about how to buy in China, as well as how to optimize BoM. It’s better not to do the first in the professional field at all if you don’t know exactly what you are going to, and whether it is possible to change all resistors on the board for three 1-10-100K values, or 0.1-percent Yageo RT0603 is better left as is, even if you have to pay extra - you know better yourself.

Printed circuit boards

Here, to be honest, there is nothing to say, we order everything from Rezonit, from Russian manufacturers they have the best combination of time, price and quality. A two-layer small board in a batch of 10-20 pieces with a production time of 4-5 days will cost you 3-4 thousand rubles per batch.

At the moment, I personally have 177 completed orders there and one in the process. The minimum batch of what we ordered there was 1 piece, the maximum - several thousand pieces.

To estimate the cost of manufacturing, there is a calculator , which is essentially no different from the usual form of ordering boards in your account — well, except for the ability to upload files and send them to the factory.

Installation

And here, of course, the most interesting begins - there are boards, components are there, then what?

The main thesis: modern boards are not manually collected with a soldering iron .

Even in pilot production. Even ten pieces. It is simply a chore, long, ineffective and poor quality. Manual soldering violates the main principle of work efficiency - monotony. Manual soldering is a constant, every second tool change in the hands. If it is not your goal to spend too much time, you can’t do that.

On modern boards, the absolute majority of components are SMD, and moreover, when you try minimally decent assembly methods, you will cry every time you have to install a THD component.

SMD components are soldered with a paste - a mixture of flux and micron-sized solder balls (we use Multicore CR36, but this is not necessary).

Paste is applied strictly to the contact pads of the components in one of two ways:

- pneumatic - with a compressor for 4-6 atmospheres (any with a receiver is suitable to ensure pressure stability) and a dispenser such as this . The dispenser stands for a hundred bucks for the Chinese and provides a simple thing - when the pedal is pressed, it feeds air into the syringe with the paste under a given pressure for a predetermined time, squeezing the prescribed amount of paste. It’s a bit of a chore, but you’ll sprinkle a medium-sized board in fifteen or twenty minutes, and with a certain skill you can even work with components 0402. Pasta for dispensers is already sold in syringes, we use EFD SolderPlus (or rather, we don’t use it, because the dispenser is at least 364 days in the year just covered with dust).

- on the stencil - a sheet of steel or plastic with holes in the contact pads cut into it, with a thickness of 100-125 microns. The stencil is put on top of the board, a slap of solder paste is thrown onto it and smeared with a spatula or just a plastic card. Ideally, this process requires a manual stencil printer that provides vertical raising and lowering of the stencil, but on a small scale you can simply fix the board and the stencil with masking tape on the table. Processing a single board takes, obviously, just a couple of minutes.

Any options with smearing toothpick, manual pressure from a syringe, etc. Forget immediately - you hang yourself on your very first board.

This part would not be so fun - the stencil piece is quite expensive - if it were not for one wonderful invention of mankind: the Silhouette Curio cutting plotter, designed to cut appliqués for scrapbooks, but also copes well with “ transparencies ” for projectors. The latter are 100 microns thick - do you think this is just a coincidence?

The plotter accepts DXF files as input (in the free version of the software; the paid one adds support for the SVG scrapbooks that are very necessary) and copes with components down to SOIC and 0603 without any problems. Passage 0402 is worse, but still acceptable, and you have to remove any QFN separate legs and make a solid slot.

This, of course, is not a stencil for the production of ten thousand devices. But the ability to make a stencil, which is quite suitable for most simple structures, on equipment for 14 thousand rubles, without wet chemistry and in general any significant waste, as well as for fifteen to twenty minutes of time - is priceless.

After cutting and spreading is the alignment of parts .

Of course, it would be nice to have an automatic balancer, but, firstly, the thing is not quite cheap, and secondly, I will tell you a secret, you will take much more time to set up the aligner for a lot of fifty motherboards than the arrangement itself.

Therefore, the base case is manual placement. The easiest and cheapest option is a vacuum tweezer of the type of this , that is, in fact, a handle with an aquarium compressor. The handle has a replaceable needle at the end and a hole in the side, close the hole with your finger - the needle attracts the parts, release the finger - the air goes through the hole, the part falls off.

Unlike conventional tweezers, this piece allows you to take components of any shape and from any surface, including directly from the bands, and unlike mechanical vacuum tweezers with a button and a rubber bulb inside, does not give a jerk when you release the part. It is worth such a penny tweezers - less than 1,500 rubles from the Chinese, and if desired, you can also make the most natural of an aquarium air compressor. Needles are eventually clogged with solder paste, but without problems, they are bought separately, either in sets of different diameters or in packages of one diameter of 10–20–50–100 pieces.

The usual tweezers will be left to place only the largest components, such as processors in LQFP-cases.

An important point: the XXI century is in the courtyard, nobody already does the layout on a paper printout from CAD .

For manual placement, there is a small and extremely useful VisualPlace program that absorbs gerberas, the list of components and their coordinates on the board - and shows you where which component should stand, and also in what orientation:

Moreover, VisualPlace is able to group the components along the value field, so that by picking up the coil of transistors SI2333 and poking the group with them, you will see all the places where they should stand.

The authors wrote the utility explicitly primarily for themselves (and, by the way, they also make a wonderful little Termite ), therefore, on the one hand, it is not overloaded with unnecessary junk and beautiful icons, on the other - there are many rough edges in understanding units of measurement (inches or millimeters), reference points of coordinates in gerberas (I recommend always starting at the bottom left corner of the board), etc. Sometimes, CAD features are superimposed on this — for example, DipTrace on a system with a Russian locale stores numbers with a decimal separator “,”, and VisualPlace waits for “.” Regardless of locale.

However, the CAD exhaust adjustment under VisualPlace takes only a few minutes, and the utility’s utility cannot be overestimated. The utility is officially free for commercial use.

Somewhere around this moment you will feel the beauty of this approach to installation. Compare - soldering iron:

- soldering iron in the right hand, solder in the left

- put a drop of solder on one resistor pad

- put off the solder, put off the soldering iron

- shake the resistor out of the tape, turn the markings up

- in the left hand tweezers, take the resistor with tweezers, put on board

- without releasing the resistor, take a soldering iron in your right hand, grab the pad onto which the solder was applied

- put away tweezers, take a solder

- grab the second platform

- repeat for the remaining 146 components

Paste:

- spread the whole paste

- take the vacuum tweezers, arrange all the components directly from the tapes and pallets

- put the board in the stove

Oh yeah. After you have placed the components (it is necessary to put them with a little effort so that they are pressed into the paste), it is time for the stoves .

The stove's task is to heat the paste at a given speed of up to 140-160 degrees (temperature of flux activation and evaporation), then up to 220-230 (melting solder), hold for a short time and cool.

Strictly speaking, it is possible to heat the paste on completely piece products with a hair dryer, but this only works for literally 5-10 copies, and also subjects the components to serious stress due to the large temperature gradients. The stove heats evenly and smoothly.

Again, which is very pleasing - although the Chinese are making quite inexpensive stoves for themselves, you can make a very self-made out of a completely worthless electric oven (I do not recommend this particular model, this is just a link) or aerogrill, adding to them an Arduino temperature controller that can withstand the right one. profile by degrees and by minutes. The cost of such a decision in the knee version will be less than 5 thousand rubles for everything in the amount.

Actually, everything. After baking, it remains on the components with small steps to check the legs for possible sticking (contrary to the statements in numerous manuals - no, the solder paste is not always ideally perfect itself on the leg, if it is slightly larger than necessary, or smeared more strongly than necessary - surface tension is not enough to break the jumper between adjacent legs), all found to remove the usual soldering iron, on chips with long legs and small steps, like LQFP or TSSOP with a step of 0.5 mm, - with braid for soldering.

Well, actually, everything. Products are mounted.

Calculate?

- cutting plotter for stencils - 14,000 rubles.

- transparent film - 500 rubles for 50 sheets

- a jar of Multicore CR36 - 500-800 rubles for 30 g (for regular work, take the banks of 500 g, it is around 4500 rubles. now)

- vacuum tweezers - 1500 rub.

- electric oven - 3000 rub.

- Arduino, relay, thermocouple - let it be another 3000 rubles.

Total - 22 800 rubles for a set of equipment and consumables, which will allow you to mount boards with SMD components several times faster than purely handmade soldering iron. And what's more, it is also of higher quality: if by the results of the soldering iron, it is immediately obvious that the board was assembled by hand (the characteristic nodules on the legs of the components, with a clear excess of solder over what was really needed), then with minimal dexterity even such a primitive set allows you to make products, non-professional point of view is not similar to the serial.

And this is for the amount that many people can afford even as part of a hobby.

And if your wife is also interested in scrapbooks ...

Source: https://habr.com/ru/post/439606/