How to make a solar flashlight do it yourself (part 2)

In the previous article, the nuances of the assembly of classic solar lanterns on a column were considered. In this article, I want to share my experience in assembling tabletop solar lanterns — nightlights and single-piece, one can say “pathetic” solar lanterns based on ready-made or crystal ceiling lamps.

Solar powered lanterns - nightlights

The reason for the appearance of these lanterns was the need to highlight the washstand under a spreading apple tree, where it is impossible to put an ordinary solar torch out of the shadows behind the shadows. Of course, as an option, it could have been put there only for the night, but without a column they could not be reliably installed, they always strive to roll away somewhere, so the idea arose to make a small steady flashlight with a flat base. In the morning it is taken out to be charged on the sun, and in the evening it is put in place. In the photo, the progenitor of my Today Solar Desktop Lanterns:

In the evening, they can also light up the table in the open air if the party is delayed, or use it as a night lamp:

The idea took root and “Today” had successors, deprived of its shortcomings in the form of low ceiling position, because for normal lighting of the table it had to constantly put some kind of stand, for example a glass like in the photo above. Flashlights "Jardine" (left) and "Grand" (right):

Due to the height and good “catchiness”, these two flashlights turned out to be much more convenient and practical and sometimes literally save, because according to the law of meanness, electricity in the summer at the dacha is sometimes turned off at the most inopportune moment. The lanterns are made of jars from the instant coffee of the same name (this is not an advertisement for coffee brands, these jars were the first to come in hand and you can use any suitable ones instead):

Slightly heated remove stickers. In the flashlight "Grand" solar panel is pasted on top of a plastic jar lid. Before gluing the knife out of the top cover with a knife, cut off the protruding inscription and thoughtfully, for example with the aid of an awl, scratch it in order to improve the adhesion of the surface to the glue:

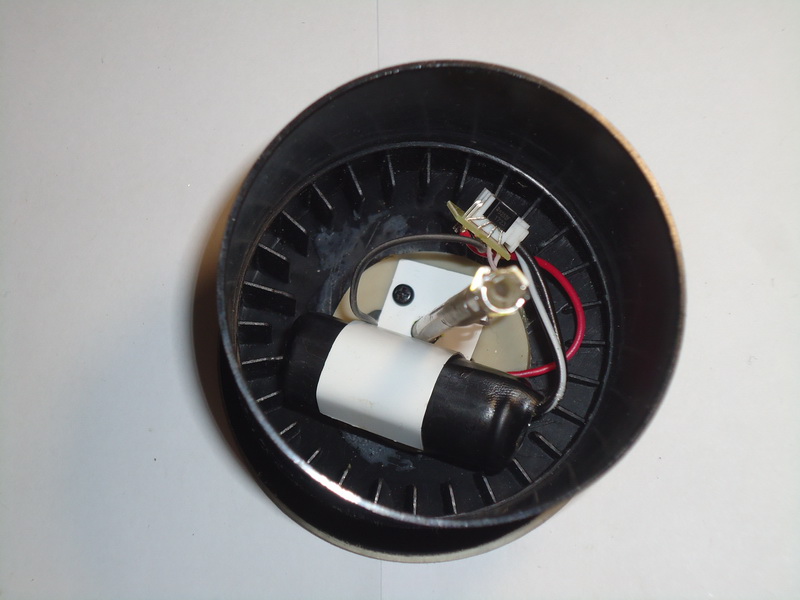

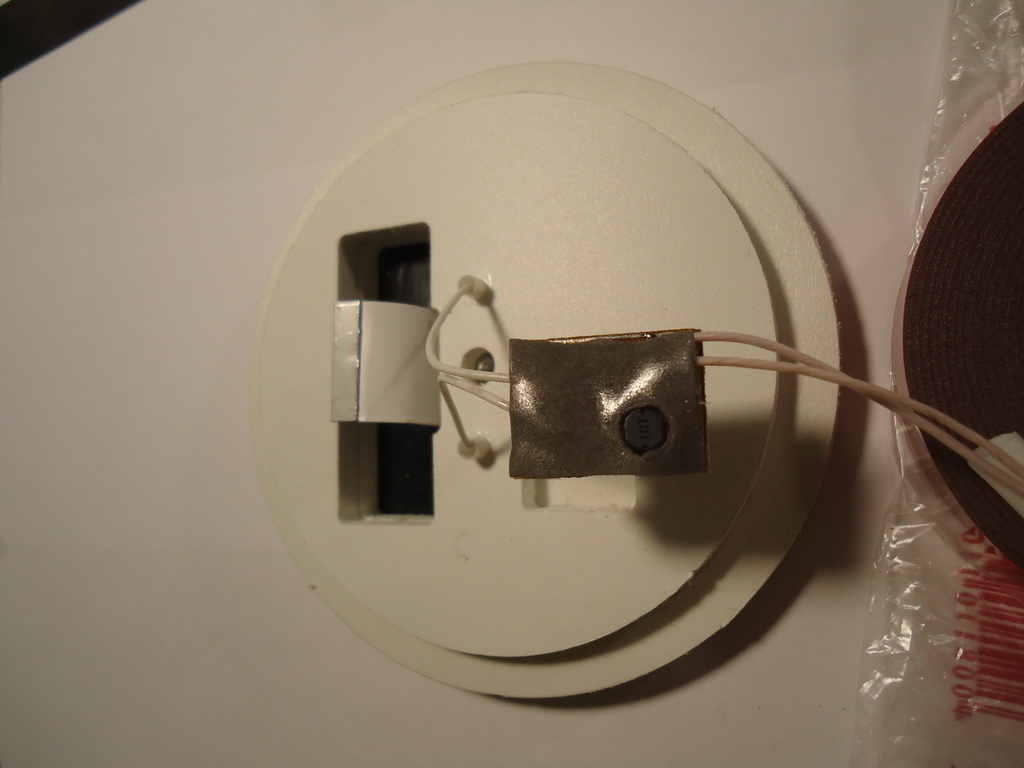

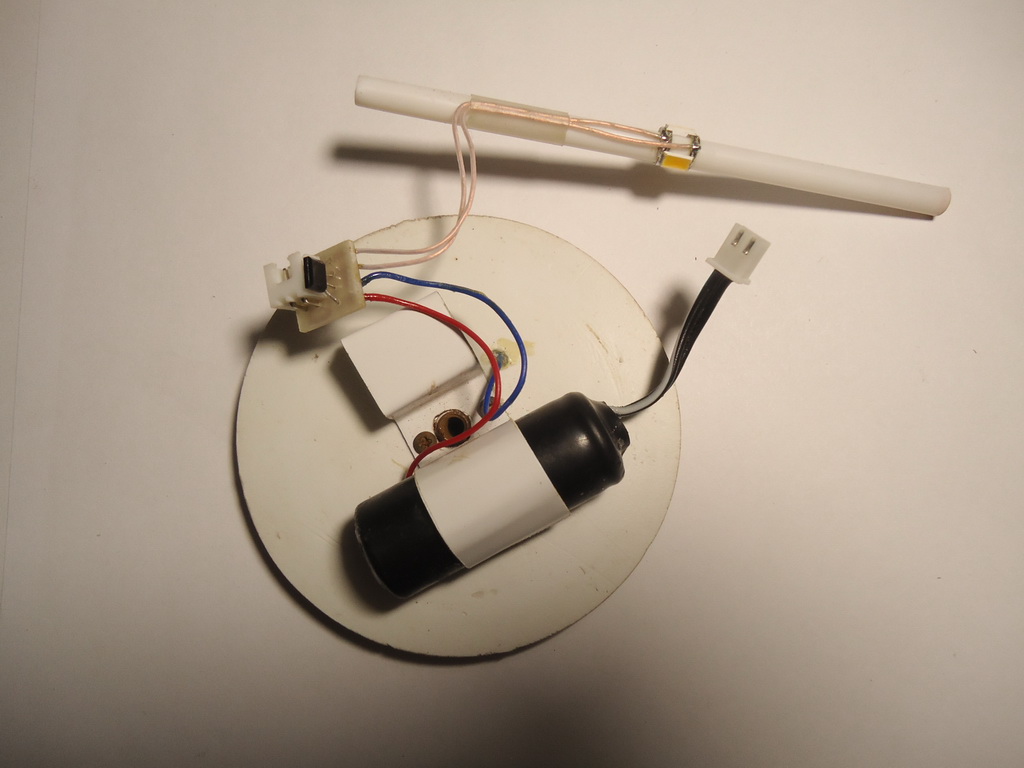

On the reverse side, a plastic base with a diameter of about 35 mm and a thickness of about 5 millimeters is glued to the lid. With the help of small self-tapping screws, an attachment bracket for the battery, cut out of roofing iron, is attached to it, and a plastic PVC tube with a diameter of 4–5 mm with LEDs mounted on it is glued into the hole in the center of the base:

Ceiling lamps are matted with a white matte film rolled up in a ring and fixed with transparent tape:

Flashlight "Jardine" is assembled in a similar way, to the contrary, in the bottom of the ceiling we drill three holes with a diameter of 6 to 8 millimeters:

And with the help of a 4 mm stud and a nut with a washer, we fix the base with the solar battery installed on it to the ceiling. The joint between the base of the solar panel and the canopy is protected from water ingress using a transparent sealant (The process of assembling the base for a solar cell and the technology of drilling holes in glass are completely similar to the one described in the article How to make a solar flashlight with your own hands (part 1) ). A PVC tube with mounted LEDs of 4-5 mm in diameter is attached to the hairpin and fastened with an M4 nut from below. The lid must make holes for draining rainwater and condensate, the electronics board and battery are located on its bottom:

The plafond is matted with a white matte film, similar to the “Grand” torch:

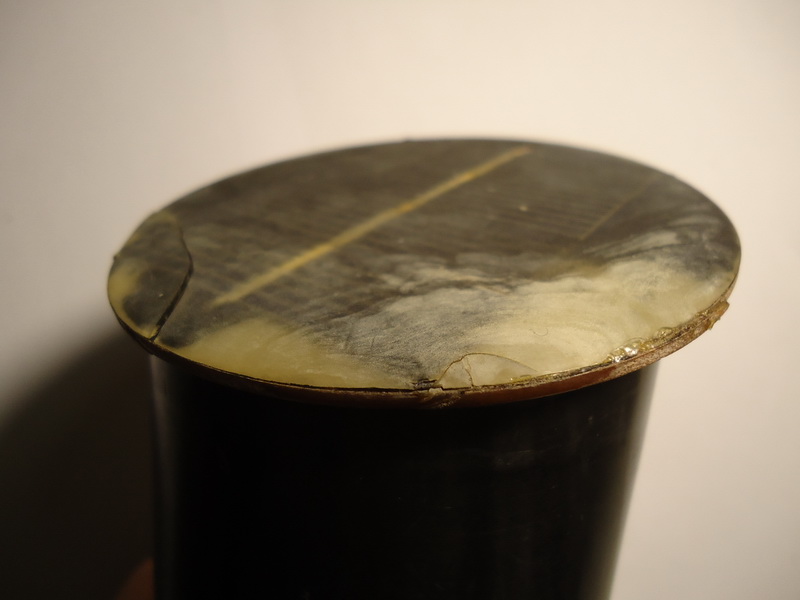

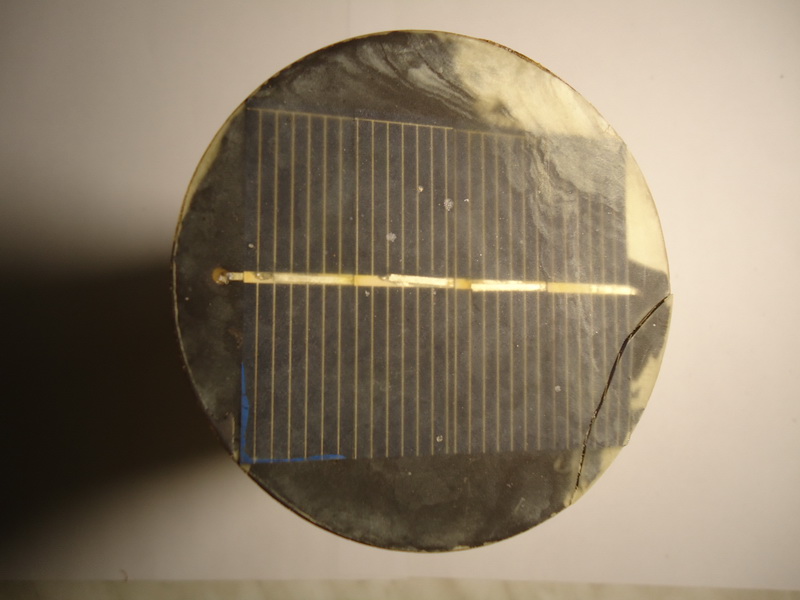

In the process of using these flashlights, it turned out that the solar panels are very sensitive to face impacts, the result in the photographs:

The transparent compound from the blows begins to peel off from the board - the base of the solar panel made of sheet steel, and the corners of the square solar panels are even more defenseless before the blows, which in general are not uncommon, the wind blew off, or someone stumbled without noticing, etc. , actually, that is why plastic protective bases appeared at the solar panels of my flashlights.

"Pathos", or piece solar lanterns on the basis of finished lampshades

Why precisely “pathos”? The fact is that ready-made ceiling lamps for chandeliers, wall lamps cost from 200 rubles and more and this significantly increases the total cost of such solar lanterns and not everyone can afford their mass use. But ... Sometimes you still want to. Let's start with a small photo gallery. On the photo is a flashlight "Chandelier" with LEDs with a color temperature of 3200K, and somewhere in the background a flashlight from the Globus is hiding:

Flashlight "Sphere":

From left to right, lanterns - “Sphere”, a lantern purchased in “Globus” and familiar from previous articles “Caprice”:

Flashlight "Lilia" is probably already familiar to many from the title photo to the article Solar lanterns - we need to be brighter :

Flashlight "Ode":

Flashlight "Ocean":

For the manufacture of solar lanterns from the photos above were used ceiling lamps from the old chandelier ("Chandelier"):

Such plafonds are made of very thin glass and fragile enough, due to the fact that one of them crashed, the chandelier had to be thrown out, and the four surviving plafonds turned into solar torches:

Ceiling lamps purchased in "Leroy" (flashlights "Sphere" and "Lily"):

Plastic and glass cups became the shades for the “Oda” and “Ocean” torches.

Flashlights Ocean and Oda actually turned out to be not entirely successful. Matting glass shades from the inside with white acrylic lacquer in several layers turned out to be time consuming, and this coating turned out to be short-lived, in the photo below you can see flashlights that served only one season and wintered in an unheated garage. It can be seen as on the left flashlight peeling lacquer, and on the right generally curled:

As practice has shown, with the location of electronics and batteries inside the ceiling, the candidate for the ceiling is better to choose moderately matt or translucent, but not to get carried away, because matting will prevent the passage of light. The use of completely transparent plafonds is not always justified from an artistic point of view, it is noticeable and striking as for example with the Bell flashlight:

Actually, because of this, it is usually placed in the far corners of the garden.

The “Ocean” flashlight let down the canopy material, after a couple of seasons of operation under the action of the sun, the plastic became quite fragile and when trying to clean it of dirt it just crumbled in the hands:

And now, using the example of the “Chandelier” flashlight, consider the assembly process:

(For details on the process of making the base of the solar battery with the M4 furniture nut, columns and pegs described in the article How to make a solar flashlight with your own hands (Part 1) . ")

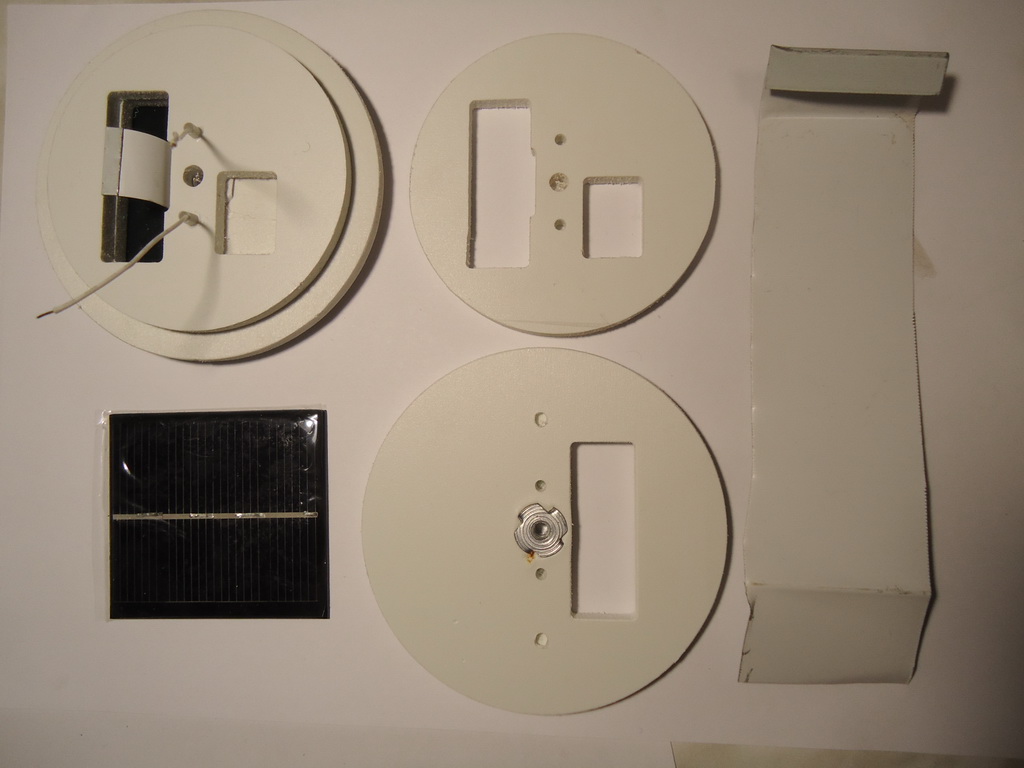

The battery mount is made from trimming roofing gland. You can also use any sheet metal from computer cases, CD-ROM, but at least cans of condensed milk. It can be glued between the base of the solar battery and the insert, as in the photo above, or fastened with two small screws:

If unprotected iron is used as a material for mounting the battery, it is better to varnish it or paint it. Remember - inside the flashlights rust and rot everything!

The electronics board is glued to a 3M double-sided tape in a specially cut niche:

You can fix the board using the battery bracket (in the photo the mount is for the old type of boards, but the general sense is generally understood):

And you can not fix, leaving hanging on the wires as shown in the photo assembly "crystal" flashlight.

In the chandeliers "Chandelier" and "Sphere" the ceiling light is clamped between two plastic inserts, and the base of the solar battery with the battery and the electronics board is wound on top of it. In “Odet” and “Ocean” the plafond is pressed from below with the help of a nut and stud through the flashlight:

As a lazy person, I cut these parts on the CNC, but they can also be made with an electric jigsaw. The photo shows the bases by which the lanterns are inserted into the posts, on the right, an Oda flashlight with an old mounting option made of PVC ceiling panels. This solution is not as reliable and durable as other flashlights, but also quite workable:

As a material of fastenings, almost any PVC sheet plastic 4-6 mm thick, Plexiglas, Winniplast, fragments of old office equipment can be used:

In the flashlight “Lilia”, because of its peculiar open ceiling, which it is impossible to completely cover with a solar panel from splashing with rain, because of which, in the first embodiment, it was filled to the brim with water, it was necessary to redo the plastic inserts between which the ceiling was mounted, making drain holes in them:

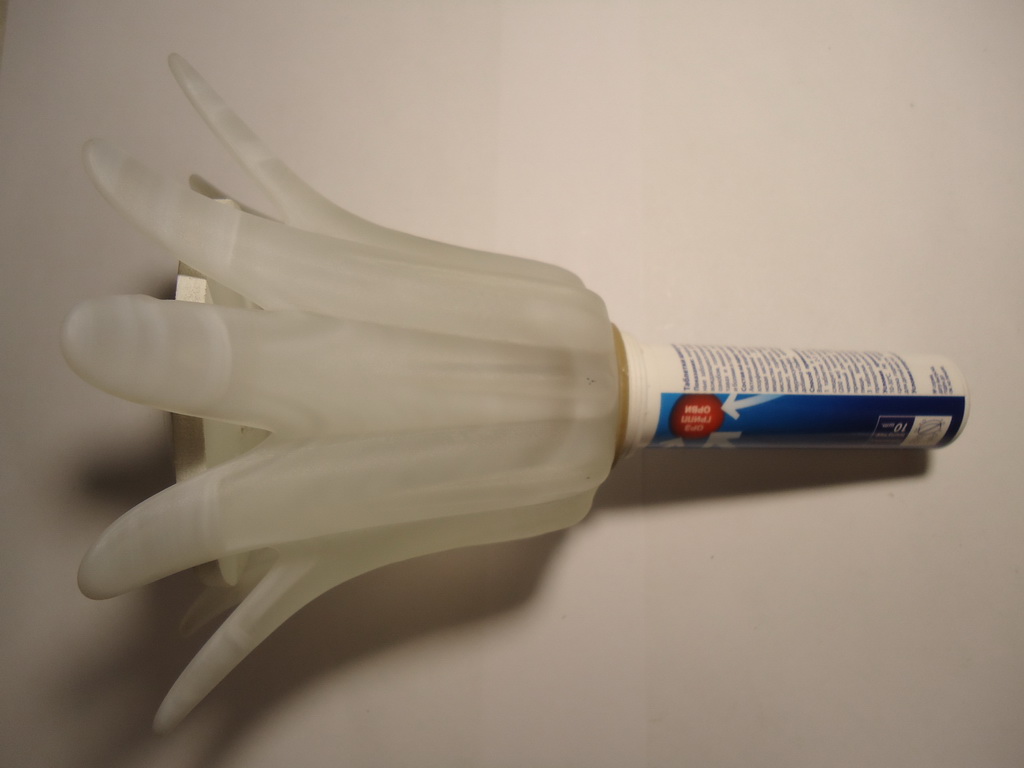

I also had to hide the electronics and battery board in a suitable plastic medicine tube:

Before assembly, a plastic spring is cut off the tube cover and the silica gel is removed:

To prevent water from entering the tube, dock its cover on the sealant:

Wires are drawn through an oval hole in the cap of the tube and a plastic washer with a slit:

The execution of the electronics and battery compartment from the medicine tube is also perfect for flashlights like “Caprice” and the like; I actually made several of my flashlights of this type in this way (until the tubes are out). In the tube it is also necessary to make drainage holes to drain the water, because despite the seeming tightness, it perfectly draws moisture and as a result, the battery and the electronics board float in the water. In just one summer month, the tube without drainage holes is about half filled with water. The result in the photo is a green battery with turned-off wires after the season of operation in a tube without drainage and two batteries with protected caps - lacquer soldering points of the wire after just one season of operation in the Sphere and Oda flashlights, on the left the battery protected by varnish and shrink film:

Crystal lanterns

Once I was sorting out the trash in the garage, I came across a pair of crystal glasses with broken legs left over from previous owners. And I thought, why not?

This is the same flashlight as in the photo above, only at the beginning of the dacha season of 2018, LEDs with a color temperature of 3000K were installed in it:

The family did not approve the replacement, “the crystal flashlight should shine with a bluish-white color,” so I had to subsequently put LEDs in it with a color temperature of 6000K.

The base of the solar battery for crystal lanterns is done in the same way as the Chandelier or Oda lanterns, with the difference that the furniture nut is not installed in the base, and a PVC plastic tube with a diameter of 4 - 5 mm is glued into the hole in the center LEDs mounted on it:

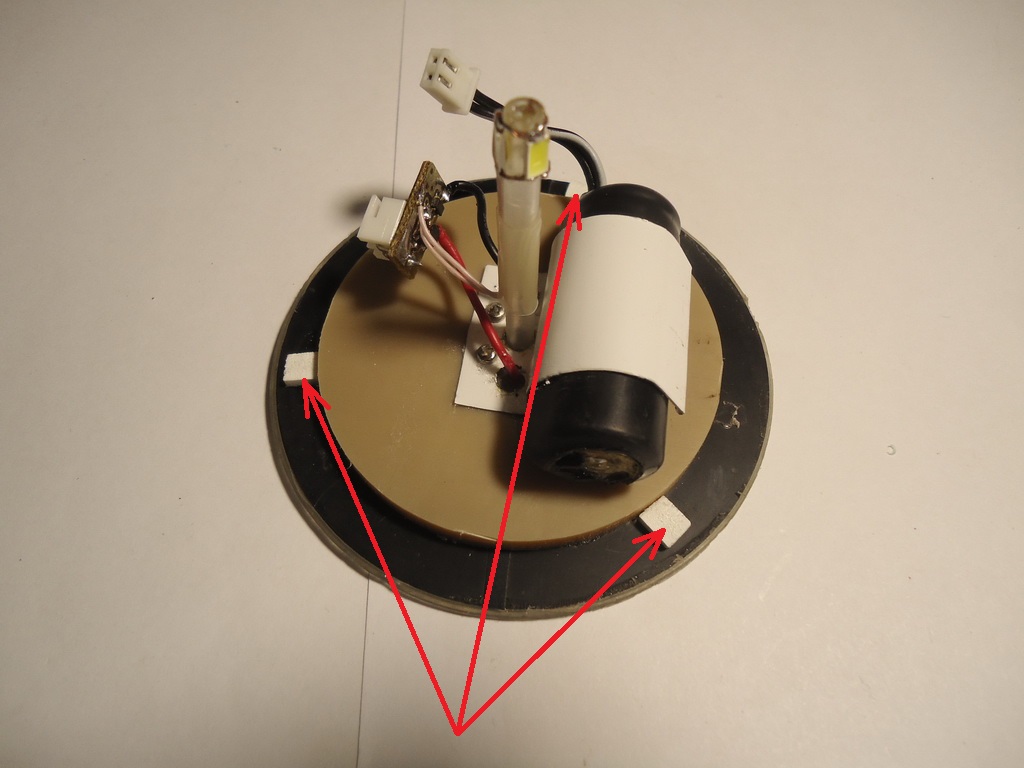

As a stand for LEDs, you can use any plastic tubule, for example, a cocktail tube, or a gel pen stem, and at least a stick from the lash - chups. The red arrows show the plastic stands installed to allow the flashlight to be ventilated. Without them, in the plafond for the month, water was practically collected to the brim, and the connectors on the board and the battery were simply turned off. The bollards to the crystal lanterns perfectly approached from the dead Chinese counterparts, but in order for them to stand exactly, the blue electrical tape must be wound on the end of the leg:

Picking up photos for this article, I was surprised to find that some photos of "crystal" and table lanterns were taken almost five years ago. “Nowadays”, these lanterns practically didn’t change, except that small scratches and sometimes “combat” rust inside were added, and in the process of evolution the electronics managed to change two or three times during this period, eventually coming to the schemes 8 ... 11 published in the article Solar lanterns - we need brighter . So in the end, despite the use of "junk" materials, these homemade products turned out to be not only brighter, but also more durable and reliable than their Chinese counterparts.

Previous Cycle Articles

A small review of solar lanterns

Solar lanterns - we need brighter

How to make a solar flashlight do it yourself (part 1)

Source: https://habr.com/ru/post/440122/